- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CL-26AB

-

Product name:

-

Silicone Sealant Glue

-

Application:

-

Kitchen products baby parts

-

Keywords:

-

Silicone primer

-

Color:

-

Transparent

-

MOQ:

-

2kg

-

Delivery Time:

-

7-15 Days

-

Feature:

-

Temperature resistance

-

Shelf life:

-

6 months

Quick Details

-

Other Names:

-

Silicone Selant

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KLB

-

Model Number:

-

CL-26AB

-

Product name:

-

Silicone Sealant Glue

-

Application:

-

Kitchen products baby parts

-

Keywords:

-

Silicone primer

-

Color:

-

Transparent

-

MOQ:

-

2kg

-

Delivery Time:

-

7-15 Days

-

Feature:

-

Temperature resistance

-

Shelf life:

-

6 months

Product Description

SILICONE PRIMER CL-26AB

CL-26AB, Silicone primer, is mainly to bond platinum curing agent-added HTV /LSR silicone with PA(Nylon), Metallics, Polyester, PET, Bakelite, Epoxy, FRP(Fibre glass) etc.

●

Silicone kitchenware

products

●

Silicone

diving products

●

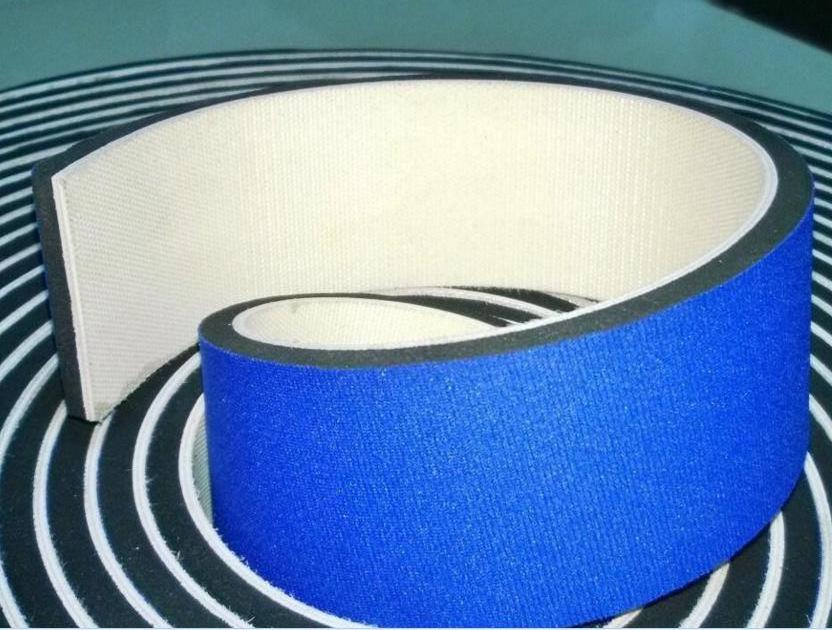

Silicone baby products, silicone parts, silicone rubber rollers

●Good adhesion

●

Long storage for after-primer-coated substrates

●High temperature tolerance for second cure of silicone rubber

|

Appearance

|

|

Transparent liquid or gel

|

|

||

|

Viscosity

|

|

<20mpa.s

|

|

||

|

Temperature Resistance:

|

|

-60~180℃

|

|

||

|

Shear Strength:

|

|

0.95 g/cm3

|

|

||

1. Treat the substrates with solvent like industrial to remove dirts and oils.

2. Mix completely the A and B with ratio 1:1 and apply the primer by dipping, brushing, spraying or silk screen printing method.

3. Leave dry in room temp for 30 minutes or baking at 110-130℃ for 15-20 minutes.

4. The primer treated substrates are processed within that day.

5. Foward the unvulcanized silicone rubber with primer-coated substrates in mouding process or hot air vulcanization.

1. Please cap its cover immediately after use to avoid volatilization.

2. Store the used and unused adhesive in separate way to lengthen the shelf life.

3. After the primer coated on the substrates, leave it volatilize completely before entering the mold, otherwise, there will be bubbles in the finished products.

4. Wash clean the substrates to remove dirts or oil to avoid bad adhesion.

5. The PA substrates is water-absorbent, it must be dried up before overmolding with silicone. Better bake with 150℃ for 1-2 hours.

Package & Storage

1000ml/Bottle or 3KG/Bottle

Keep the product sealed, stored at 20℃-25℃ away from fire, light and heat. Shelf life for 6 months.

Hot Searches