- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CNC machining services

-

Brand Name:

-

Chengmingde

-

Product name:

-

Customized Cnc Machining Parts

-

Material:

-

Stainless steel, metal, aluminum, titanium, brass

-

Process:

-

CNC Milling Turning Part

-

Application:

-

Industrial Equipment

-

Service:

-

OEM ODM

-

Surface treatment:

-

Customer's Request

-

MOQ:

-

Small Orders Accepted

-

QC Control:

-

100% QC Steps Inspection

-

Certification:

-

ISO9001:2015

-

Delivery Time:

-

Mass Production: 7-15 Days

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

CNC machining services

-

Brand Name:

-

Chengmingde

-

Product name:

-

Customized Cnc Machining Parts

-

Material:

-

Stainless steel, metal, aluminum, titanium, brass

-

Process:

-

CNC Milling Turning Part

-

Application:

-

Industrial Equipment

-

Service:

-

OEM ODM

-

Surface treatment:

-

Customer's Request

-

MOQ:

-

Small Orders Accepted

-

QC Control:

-

100% QC Steps Inspection

-

Certification:

-

ISO9001:2015

-

Delivery Time:

-

Mass Production: 7-15 Days

Product Description

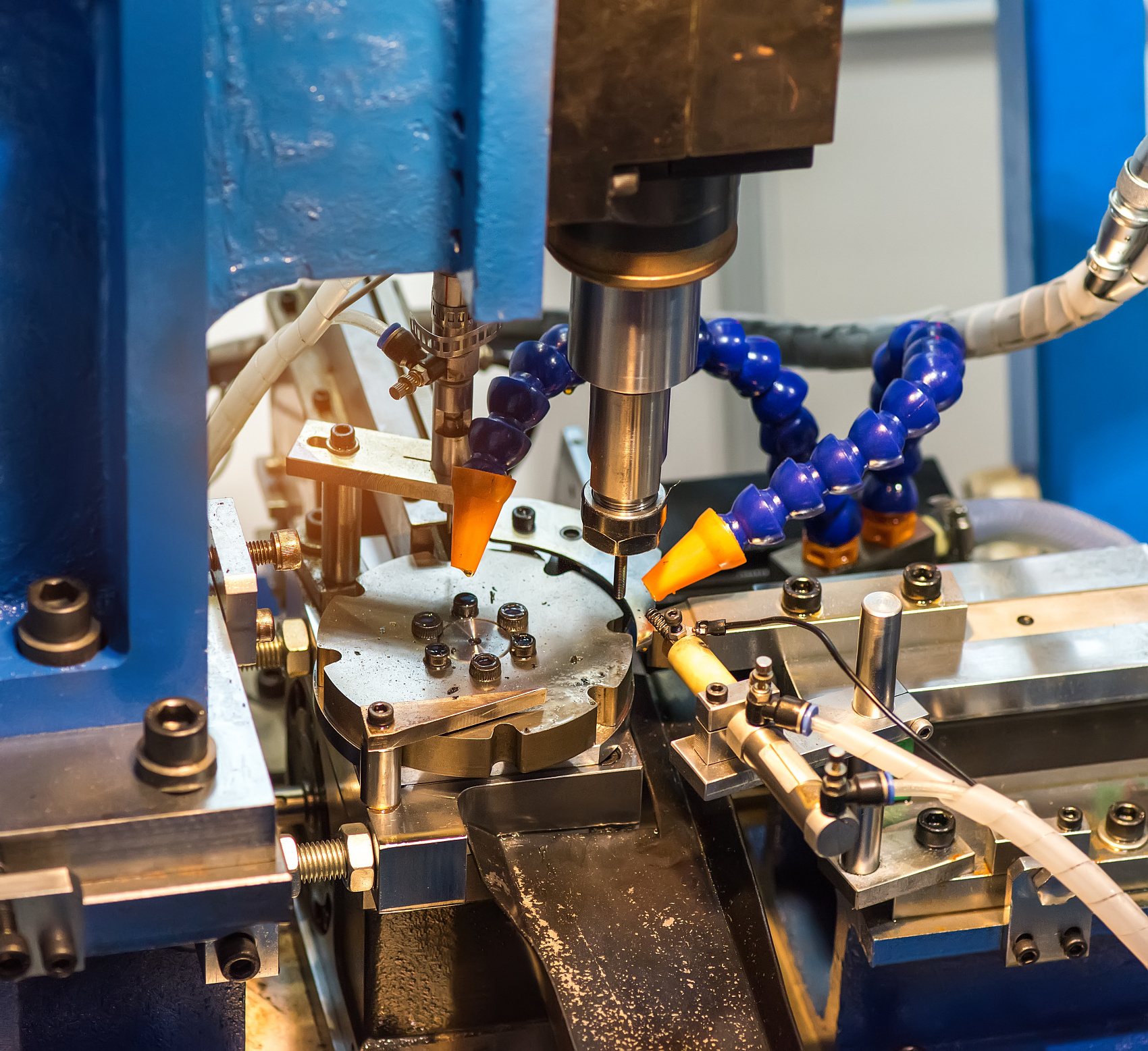

CNC Turning Processing

Our CNC turning and milling services can

produce highly accurate and complex

parts from a variety of materials, including

metals, plastics,and composites.

Samples: 1-3 Day

Lead time:7-14Day

Machinery Axis: 3,4,5,6 Tolerance:+/- 0.01mm

Special Areas : +/-0.002mm

Surface Roughness: Ra 0.1~3.2

Supply Ability:300000Piece/Month

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Specification

|

Main equipment

|

CNC Turning, CNC Milling,CNC lathes, turning and milling compounds, CNC centering machines, automatic lathes, CNC machining centers, screw machines, tooth rubbing machines, laser machine cutting, grinding machines, milling machines, and other equipment

|

|

|

|

|||

|

Materials |

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|

|

|

|||

|

|

Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

|

|

|

|

|||

|

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc.

|

|

|

|

|||

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|

|

|

|||

|

|

Titanium: Grade F1-F5

|

|

|

|

|||

|

|

|

|

|

|

|||

|

Surface Treatment |

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc.

|

|

|

|

|||

|

Tolerance

|

±0.002 ~ ±0.005mm

|

|

|

|

|||

|

Surface Roughness

|

Min Ra 0.1~3.2

|

|

|

|

|||

|

Drawing format

|

Dag, Dirk, Pudf, Solid Vaux, Potte, Stepp, Stepp, Is, etc

|

|

|

|

|||

|

Application

|

Construction industry/new energy/petrochemical industry/shipbuilding industry/railway construction/bridge sleeping

|

|

|

|

|||

Hot Searches