- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

Colorful

-

Name:

-

Masterbatch for 3D printing filament

-

Color:

-

Customized

-

Usage:

-

1%-4%

-

Carrier:

-

PP PE ABS PS PVC PLA

-

Certificate:

-

ISO 9001 ROHS

-

Sun resistance grade:

-

6-8

-

Temperature resistance:

-

170-300℃

-

Other Name:

-

PLA Silk Masterbatch

-

Appearance:

-

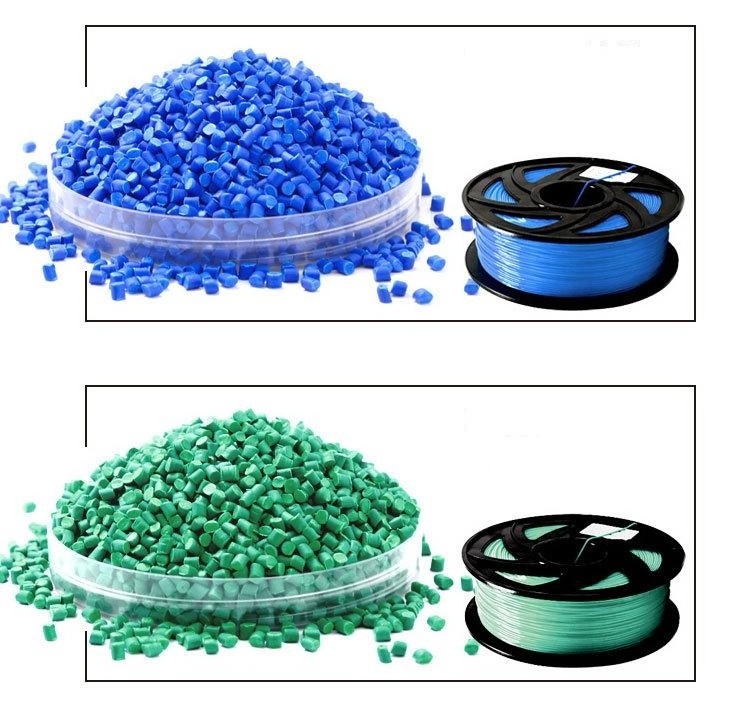

Granule Pellets

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XINYANG

-

color:

-

Red, Blue, Yellow

-

Shape:

-

Colorful

-

Name:

-

Masterbatch for 3D printing filament

-

Color:

-

Customized

-

Usage:

-

1%-4%

-

Carrier:

-

PP PE ABS PS PVC PLA

-

Certificate:

-

ISO 9001 ROHS

-

Sun resistance grade:

-

6-8

-

Temperature resistance:

-

170-300℃

-

Other Name:

-

PLA Silk Masterbatch

-

Appearance:

-

Granule Pellets

Products Description

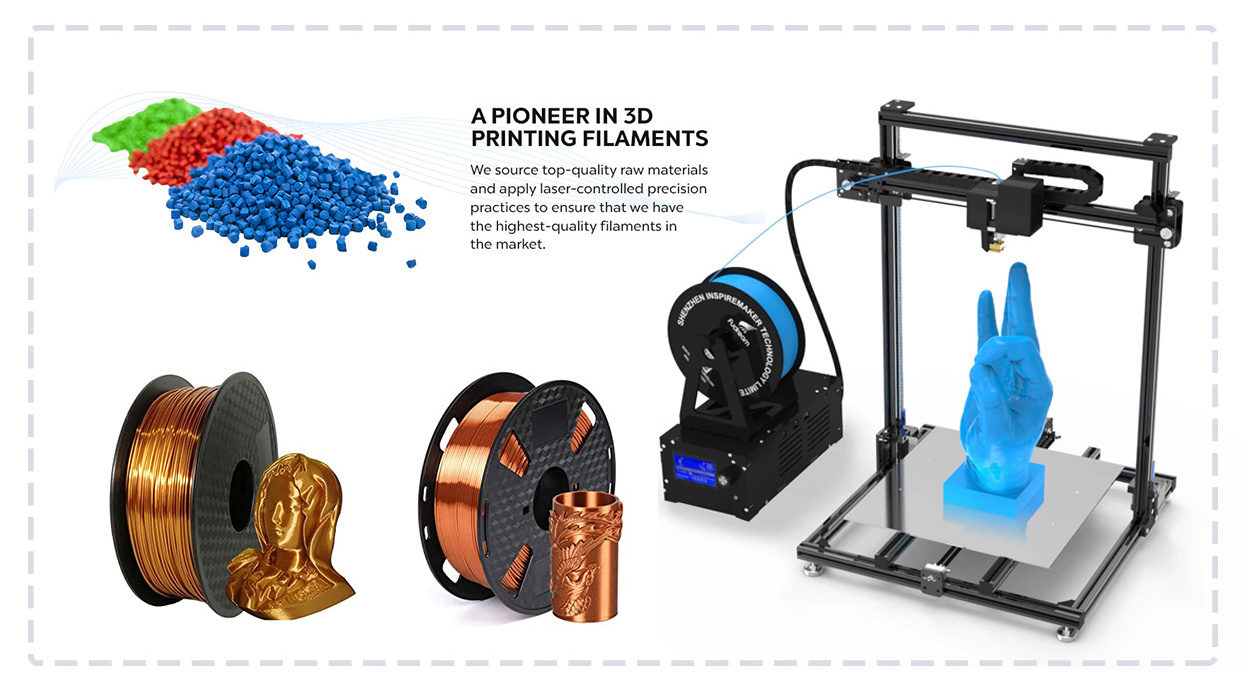

The overall introduction of masterbatch for 3D printing filament

Pigment to create filament for 3D printing. These masterbatch are added to the pellets to achieve the desired colour in the filament or prints. The pigments are suitable for contact with foodstuffs.

Characteristics

The pigments have a high processing spectrum (160 – 280 ºC). High concentration power The recommended additive quantities are between 1% – 3%. Uses of 3D Printing Pigments These pigments are mixed with pellets to achieve a homogeneous colour. The pellet can be used to create 3D printing filaments, but can also be printed directly from an extruder printer such as the v4 Pellet Extruder.

Detailed Introduction

Performance and advantages:

High brightness

High covering

Strong shading

Strong tinting power

Uniform dispersion

Good solubility

Environment-friendly

Application

Production technology:

1. Equipment: conical twin screw extruder

2. Reference production temperature: about 150 ~ 300 ℃

3. Addition rate: 2-4% (according to product requirements, usually 1-4%)

Usage method:

2. Reference production temperature: about 150 ~ 300 ℃

3. Addition rate: 2-4% (according to product requirements, usually 1-4%)

1.One kilogram of Multicolor PLA modified plastic can produce a roll of multicolor 3D Printing filament .

2.If you want a roll of multicolor 3D printing filament to show five colors,They are maybe red, blue, green, purple, yellow.

3.Divide 1 kilogram of multicolor PLA modified plastic into five equal parts, 200 grams each.

4.Mix different toner with 200g multicolor PLA modified plastics.

5 Pour 200 grams of multicolor PLA modified plastic mixed with different toner into the material barrel in turn.

For example, First ,pour 200 grams of Multicolor PLA modified plastic mixed with red color toner , then pour 200 grams of

multicolor PLA modified plastic mixed with green color toner after the 200g Multicolor PLA modified plastic mixed red color toner are used up, and when 200 grams of multicolor PLA modified plastic mixed with green color toner are used up, 200 grams of multicolor PLA modified plastic mixed with yellow color toner are immediately poured ……and so on

6. Toner addition ratio:adding proportion of different toner is different, you can adjust according to your own color

requirements, or you can refer to the proportion of toner and PLA raw materials for 3D printing Filament .

For example :If you usually need 10kg PLA raw material and 50g red toner to produce a roll of red 3D printing filament , when you produce multi-color 3D printing filament ,200g multi-color PLA modified plastic just need to mix with 1g red toner.

2.If you want a roll of multicolor 3D printing filament to show five colors,They are maybe red, blue, green, purple, yellow.

3.Divide 1 kilogram of multicolor PLA modified plastic into five equal parts, 200 grams each.

4.Mix different toner with 200g multicolor PLA modified plastics.

5 Pour 200 grams of multicolor PLA modified plastic mixed with different toner into the material barrel in turn.

For example, First ,pour 200 grams of Multicolor PLA modified plastic mixed with red color toner , then pour 200 grams of

multicolor PLA modified plastic mixed with green color toner after the 200g Multicolor PLA modified plastic mixed red color toner are used up, and when 200 grams of multicolor PLA modified plastic mixed with green color toner are used up, 200 grams of multicolor PLA modified plastic mixed with yellow color toner are immediately poured ……and so on

6. Toner addition ratio:adding proportion of different toner is different, you can adjust according to your own color

requirements, or you can refer to the proportion of toner and PLA raw materials for 3D printing Filament .

For example :If you usually need 10kg PLA raw material and 50g red toner to produce a roll of red 3D printing filament , when you produce multi-color 3D printing filament ,200g multi-color PLA modified plastic just need to mix with 1g red toner.

Packing& Delivery

1.Products are shipped via sea ,air flight .EMS ,DHL ,UPS ,Fedex ,TNT ect .

2. L/C . t/T . escrow. western union ,paypal ,Visa available.

3.1-15 days delivery upon receiving payment.

4. Warranty : 3 years

5. packing : paper-poly pouch ( net weight 25/kg piece .)

2. L/C . t/T . escrow. western union ,paypal ,Visa available.

3.1-15 days delivery upon receiving payment.

4. Warranty : 3 years

5. packing : paper-poly pouch ( net weight 25/kg piece .)

Hot Searches