- Product Details

- {{item.text}}

Quick Details

-

Color:

-

red, brown, green, light grey or customized

-

Brand name:

-

NENGXING

-

Other:

-

OEM service

-

Certification:

-

ISO, GB/T, IEC and etc.

-

Size:

-

Customized Size

-

Product name:

-

electrical composite polymer line post/strain insulator

Quick Details

-

Place of Origin:

-

Jilin, China

-

Brand Name:

-

Nengxing Power

-

Model Number:

-

FSP Series

-

Color:

-

red, brown, green, light grey or customized

-

Brand name:

-

NENGXING

-

Other:

-

OEM service

-

Certification:

-

ISO, GB/T, IEC and etc.

-

Size:

-

Customized Size

-

Product name:

-

electrical composite polymer line post/strain insulator

| No. | Model | Rated voltage | Rated mechanical tensile load | connecting structure sign | Structure height H | Minimum arc distance | Minimum nominal creepage distance | Lightning full impulse withstand voltage (peak) | Switching impulse withstand voltage(wet) | Power frequency withstand voltage (wet) |

| ≥ | ≥ | ≥ | ||||||||

| kV | kN | mm | mm | mm | kV | kV | kV | |||

| 1 | FXBW-10/70 | 10 | 70 | 16 | 310 | 130 | 350 | 75 | - | 42 |

| 2 | FXBW-35/70-1 | 35 | 70 | 16 | 670 | 500 | 810 | 230 | - | 95 |

| 3 | FXBW-35/70-2 | 35 | 70 | 16 | 670 | 500 | 1015 | 230 | - | 95 |

| 4 | FXBW-66/70-1 | 66 | 70 | 16 | 870 | 700 | 1650 | 410 | - | 185 |

| 5 | FXBW-66/70-2 | 66 | 70 | 16 | 940 | 750 | 1920 | 410 | - | 185 |

| 6 | FXBW-66/120-1 | 66 | 120 | 16 | 870 | 700 | 1650 | 410 | - | 185 |

| 7 | FXBW-66/120-2 | 66 | 120 | 16 | 940 | 720 | 1920 | 410 | - | 185 |

| 8 | FXBW-110/70-1 | 110 | 70 | 16 | 1240 | 1050 | 2520 | 550 | - | 230 |

| 9 | FXBW-110/70-2 | 110 | 70 | 16 | 1240 | 1050 | 3150 | 550 | - | 230 |

| 10 | FXBW-110/70-3 | 110 | 70 | 16 | 1440 | 1250 | 3520 | 550 | - | 230 |

| 11 | FXBW-110/120-1 | 110 | 120 | 16 | 1240 | 1010 | 2520 | 550 | - | 230 |

| 12 | FXBW-110/120-2 | 110 | 120 | 16 | 1240 | 1010 | 3150 | 550 | - | 230 |

| 13 | FXBW-110120-3 | 110 | 120 | 16 | 1440 | 1210 | 3520 | 550 | - | 230 |

| 14 | FXBW-110/160-1 | 110 | 160 | 20 | 1340 | 1030 | 3150 | 550 | - | 230 |

| 15 | FXBW-110/160-2 | 110 | 160 | 20 | 1440 | 1130 | 3520 | 550 | - | 230 |

| 16 | FXBW-220/120-1 | 220 | 120 | 16 | 2240 | 2015 | 5040 | 1000 | - | 395 |

| 17 | FXBW-220/120-2 | 220 | 120 | 16 | 2350 | 2125 | 6340 | 1000 | - | 395 |

| 18 | FXBW-220/120-3 | 220 | 120 | 16 | 2470 | 2245 | 7040 | 1000 | - | 395 |

| 19 | FXBW-220/160-1 | 220 | 160 | 20 | 2240 | 1930 | 5040 | 1000 | - | 395 |

| 20 | FXBW-220/160-2 | 220 | 160 | 20 | 2350 | 2040 | 6340 | 1000 | - | 395 |

| 21 | FXBW-220/160-3 | 220 | 160 | 20 | 2470 | 2160 | 7040 | 1000 | - | 395 |

| 22 | FXBW-220/210-1 | 220 | 210 | 20 | 2350 | 2000 | 6340 | 1000 | - | 395 |

| 23 | FXBW-220/210-2 | 220 | 210 | 20 | 2470 | 2120 | 7040 | 1000 | - | 395 |

| 24 | FXBW-330/120-1 | 330 | 120 | 16 | 2930 | 2690 | 7260 | 1420 | 950 | 570 |

| 25 | FXBW-330/120-2 | 330 | 120 | 16 | 3150 | 2910 | 9240 | 1420 | 950 | 570 |

| 26 | FXBW-330/120-3 | 330 | 120 | 16 | 3350 | 3110 | 10560 | 1420 | 950 | 570 |

| 27 | FXBW-330/160-1 | 330 | 160 | 20 | 2930 | 2620 | 7260 | 1420 | 950 | 570 |

| 28 | FXBW-330/160-2 | 330 | 160 | 20 | 3150 | 2840 | 9240 | 1420 | 950 | 570 |

| 29 | FXBW-330/160-3 | 330 | 160 | 20 | 3350 | 3040 | 10560 | 1420 | 950 | 570 |

| 30 | FXBW-330/210-1 | 330 | 210 | 20 | 2930 | 2580 | 7260 | 1420 | 950 | 570 |

| 31 | FXBW-330/210-2 | 330 | 210 | 20 | 3150 | 2800 | 9240 | 1420 | 950 | 570 |

| 32 | FXBW-330/210-3 | 330 | 210 | 20 | 3350 | 3000 | 10560 | 1420 | 950 | 570 |

| 33 | FXBW-500/120-1 | 500 | 120 | 16 | 4050 | 3800 | 11000 | 2050 | 1240 | 740 |

| 34 | FXBW-500/120-2 | 500 | 120 | 16 | 4450 | 4200 | 14000 | 2050 | 1240 | 740 |

| 35 | FXBW-500/120-3 | 500 | 120 | 16 | 4900 | 4650 | 16000 | 2050 | 1240 | 740 |

| 36 | FXBW-500/160-1 | 500 | 160 | 20 | 4050 | 3740 | 11000 | 2050 | 1240 | 740 |

| 37 | FXBW-500/160-2 | 500 | 160 | 20 | 4450 | 4140 | 14000 | 2050 | 1240 | 740 |

| 38 | FXBW-500/160-3 | 500 | 160 | 20 | 4900 | 4590 | 16000 | 2050 | 1240 | 740 |

| 39 | FXBW-500/210-1 | 500 | 210 | 20 | 4050 | 3700 | 11000 | 2050 | 1240 | 740 |

| 40 | FXBW-500/210-2 | 500 | 210 | 20 | 4450 | 4100 | 14000 | 2050 | 1240 | 740 |

| 41 | FXBW-500/210-3 | 500 | 210 | 20 | 4900 | 4550 | 16000 | 2050 | 1240 | 740 |

| 42 | FXBW-500/300-1 | 500 | 300 | 24 | 4450 | 4030 | 14000 | 2050 | 1240 | 740 |

| 43 | FXBW-500/300-2 | 300 | 300 | 24 | 4900 | 4480 | 16000 | 2050 | 1240 | 740 |

| 44 | FXBW-500/420-1 | 500 | 420 | 28 | 4450 | 3960 | 14000 | 2050 | 1240 | 740 |

| 45 | FXBW-500/420-2 | 500 | 420 | 28 | 4900 | 4410 | 16000 | 2050 | 1240 | 740 |

| 46 | FXBW-750/120 | 750 | 120 | 16 | 7150 | 6840 | 23500 | 2700 | 1800 | 1050 |

| 47 | FXBW-750/120-G | 750 | 120 | 16 | 7350 | 7040 | 24150 | 2700 | 1800 | 950 |

| 48 | FXBW-750/210 | 750 | 210 | 20 | 7150 | 6800 | 23500 | 2700 | 1800 | 1050 |

| 49 | FXBW-750/210-G | 750 | 210 | 20 | 7350 | 7000 | 24150 | 2700 | 1800 | 950 |

| 50 | FXBW-750/300 | 750 | 300 | 24 | 7150 | 6730 | 23500 | 2700 | 1800 | 1050 |

| 51 | FXBW-750/300-G | 750 | 300 | 24 | 7350 | 6930 | 24150 | 2700 | 1800 | 950 |

| 52 | FXBW-750/420 | 750 | 420 | 28 | 7150 | 6660 | 23500 | 2700 | 1800 | 1050 |

| 53 | FXBW-750/420-G | 750 | 420 | 28 | 7350 | 6860 | 24150 | 2700 | 1800 | 950 |

| 54 | FXBW-750/550 | 750 | 550 | 32 | 7150 | 6610 | 23500 | 2700 | 1800 | 1050 |

| 55 | FXBW-1000/210 | 1000 | 210 | 20 | 9000 | 8650 | 32000 | 3200 | 1950 | 1300 |

| 56 | FXBW-1000/210 | 1000 | 210 | 20 | 9750 | 9400 | 32000 | 3200 | 1950 | 1300 |

| 57 | FXBW-1000/300 | 1000 | 300 | 24 | 9000 | 8580 | 32000 | 3200 | 1950 | 1300 |

| 58 | FXBW-1000/300 | 1000 | 300 | 24 | 9750 | 9330 | 32000 | 3200 | 1950 | 1300 |

| 59 | FXBW-1000/420 | 1000 | 420 | 28 | 9000 | 8510 | 32000 | 3200 | 1950 | 1300 |

| 60 | FXBW-1000/420 | 1000 | 420 | 28 | 9750 | 9260 | 32000 | 3200 | 1950 | 1300 |

| 61 | FXBW-1000/550 | 1000 | 550 | 32 | 9000 | 8460 | 32000 | 3200 | 1950 | 1300 |

| 62 | FXBW-1000/550 | 1000 | 550 | 32 | 9750 | 9210 | 32000 | 3200 | 1950 | 1300 |

The company now produces all kinds of composite insulators of 1000 kV and lower voltage grades. The products have passed the latest standard IEC61109, GB/T19519- 2014<Certain Definition, Test Method and Acceptance Criteria of Composite Insulators for AC Overhead Lines with Nominal Voltage Above 1000V> by the National Inspection Center of Wuhan High Voltage Research Institute. The mechanical and electrical performances ofthe project test exceed the national standards.

In addition to the good performance of common composite insulators, the composite insulators produced by our company have the following characteristics:

©Silicone rubber shed adopts integral injection technology, which solves the key problem affecting the reliability of composite insulators - interface electrical breakdown.

©High mechanical strength, internal load-bearing epoxy glass fiber diverter rod using ECR acid-resistant mandrel, corrosion resistance is stronger.

©The unique three-way waterproof sealing technology and the use of imported adhesive have fundamentally solved the problems of unsatisfactory sealing at the end of composite insulators and damp internal insulation.

©The thickness of the silicone rubber shed has doubled that of the national standard. The material used is strict. The insulator has strong resistance to electric corrosion. The leakage mark of the shed material reaches TMA4.5 grade. It has better anti-aging and anti-corrosion performance.

The special insulator for 45 kN~120 kN wire drawing is developed and manufactured, which solves the problems of low tensile strength of porcelain insulator and fragile porcelain skirt, and effectively prevents the accidents of live injury of high and low voltage wire drawing.

Our company can provide composite insulators of different specifications and different connection modes according to the needs of users.

Our company can provide composite insulators of different specifications and modes accordingtothe needs of customers.

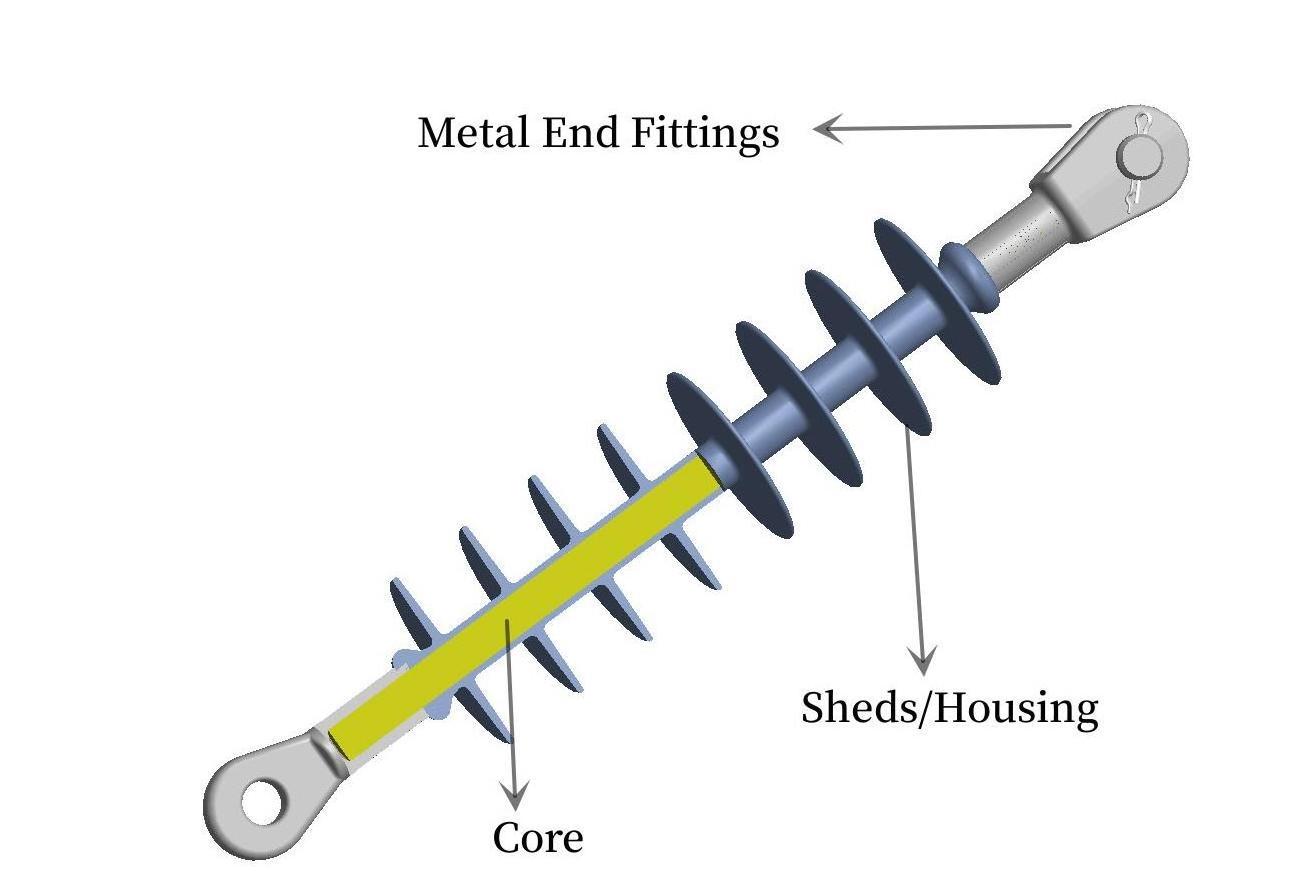

1).Silicon Rubber for sheds/housing.

2).Glass-fiber reinforced epoxy resin rod (ECR type) for core.

3).Hot dip galvanized cast steel for metal fittings.

4).1000hours aging test & Prototype Test & Type Test & Factory Test ( Routine and Sampling Test ).

5).IEC / ANSI / GB standard.