Vibrating knife cutting machine is a commonly used cutting equipment in textile, leather, automobile and other industries.

Itutilizes a rotating blade that oscillates or rotates at high speed to cut a variety of materials, including fabrics.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

cnc cutting machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Realtop

-

Power:

-

11Kw

-

Dimension(L*W*H):

-

2300*3560*1221mm

-

Weight:

-

1200 KG

-

Features:

-

cnc oscillating knife leather cutting machine

-

Product name:

-

Oscillating Knife Cutting Machine

-

Cutting materials:

-

Denim, Fabric, cloth, paper, leather and so on

-

Item Name:

-

Oscillating Vibrating Knife Cloth Cutting Machine

-

Cutting Speed:

-

1000m/s

-

Motor:

-

Delta Servo Motor

-

Cutting precision:

-

≤0.1mm

-

Cutting thickness:

-

50mm

-

Resolution ratio:

-

0.025mm

-

Cutting area:

-

1600*2500mm

-

Size:

-

customizable

Quick Details

-

Production Capacity:

-

50 sets/month

-

Voltage:

-

380v/220v

-

Marketing Type:

-

New Product 2023

-

Application:

-

cnc cutting machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Realtop

-

Power:

-

11Kw

-

Dimension(L*W*H):

-

2300*3560*1221mm

-

Weight:

-

1200 KG

-

Features:

-

cnc oscillating knife leather cutting machine

-

Product name:

-

Oscillating Knife Cutting Machine

-

Cutting materials:

-

Denim, Fabric, cloth, paper, leather and so on

-

Item Name:

-

Oscillating Vibrating Knife Cloth Cutting Machine

-

Cutting Speed:

-

1000m/s

-

Motor:

-

Delta Servo Motor

-

Cutting precision:

-

≤0.1mm

-

Cutting thickness:

-

50mm

-

Resolution ratio:

-

0.025mm

-

Cutting area:

-

1600*2500mm

-

Size:

-

customizable

Product Description

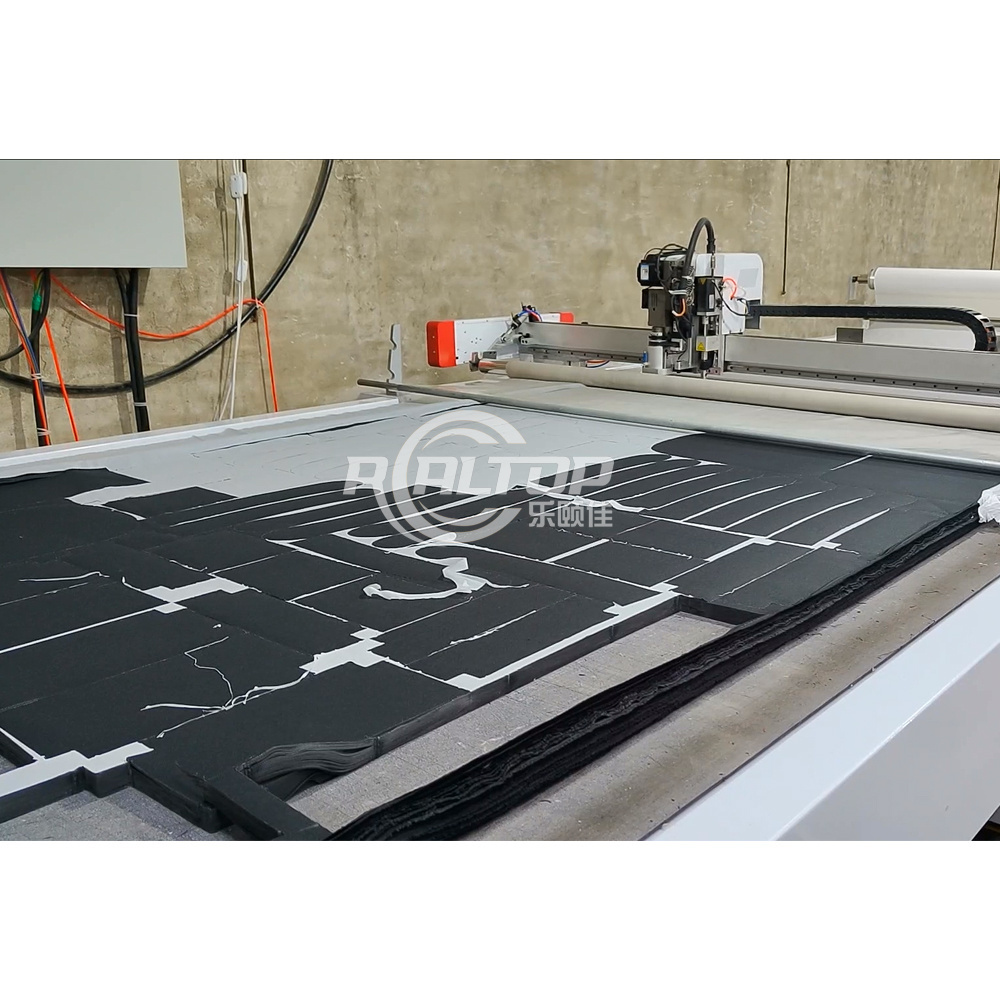

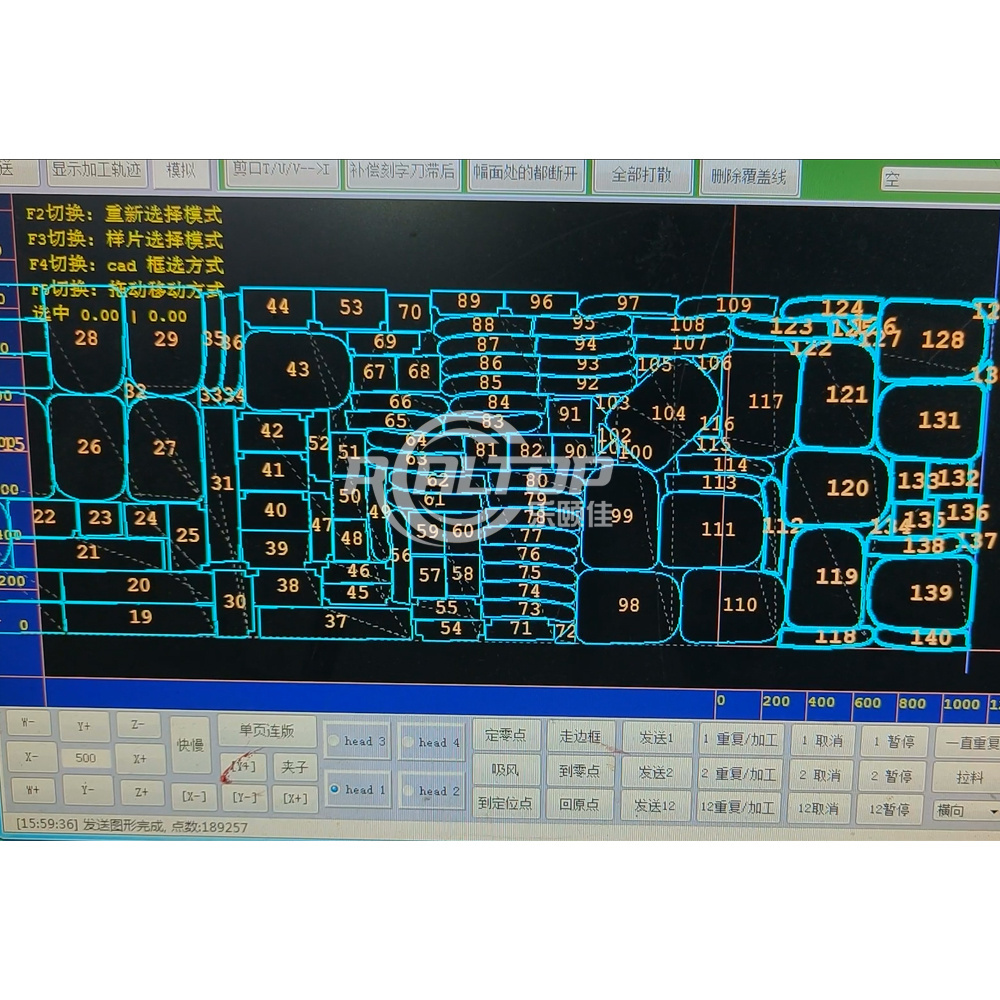

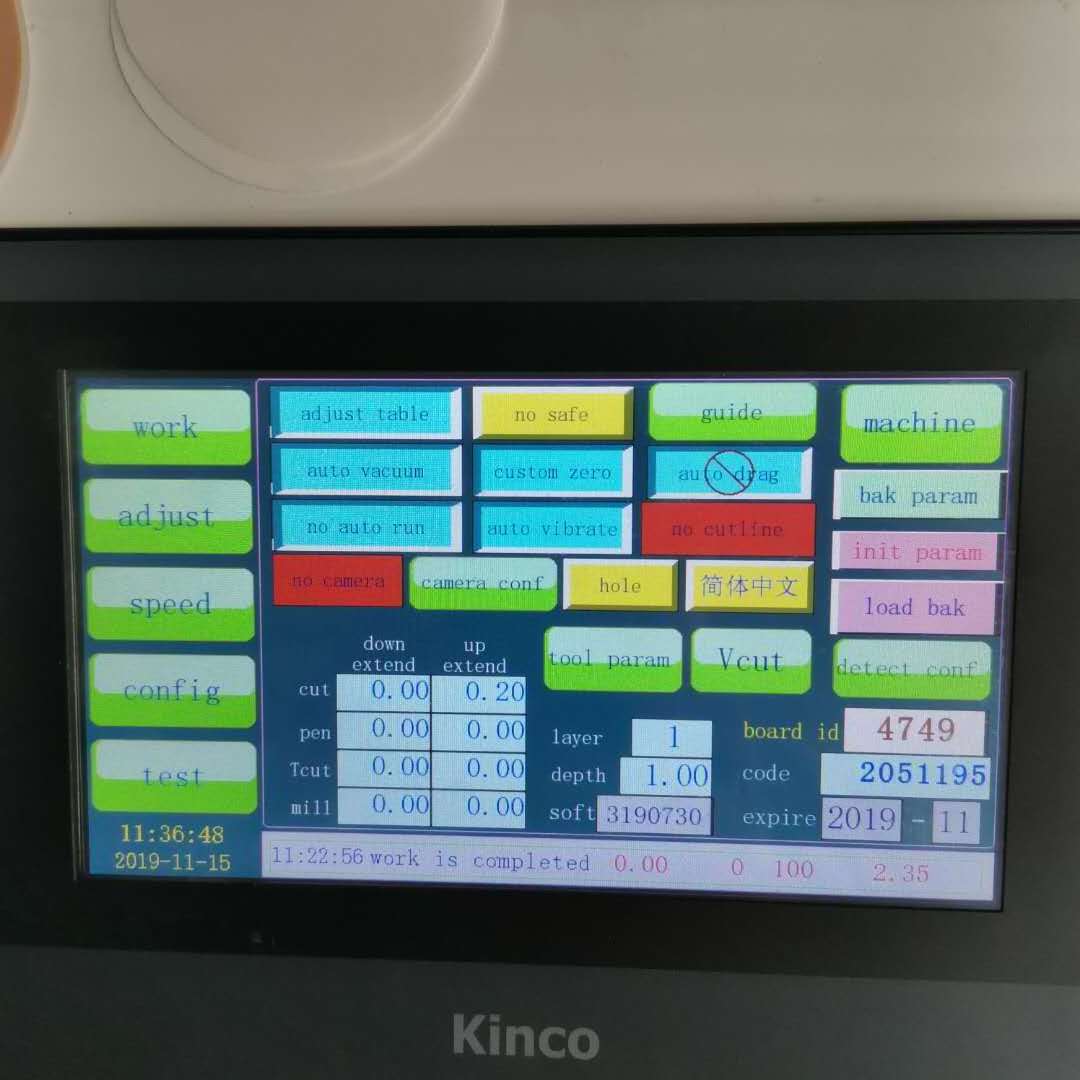

Vibrating knife cutting machines are equipped with advanced features such as computer numerical control (CNC) systems that can automatically cut according to a predetermined pattern or design. This increases productivity and accuracy while reducing manual labor.

1.

Precision: REALTOP CNC fabric cutting machines are known for their precise cutting capabilities, ensuring clean cuts and minimizing material waste through oscillating or rotating blades.

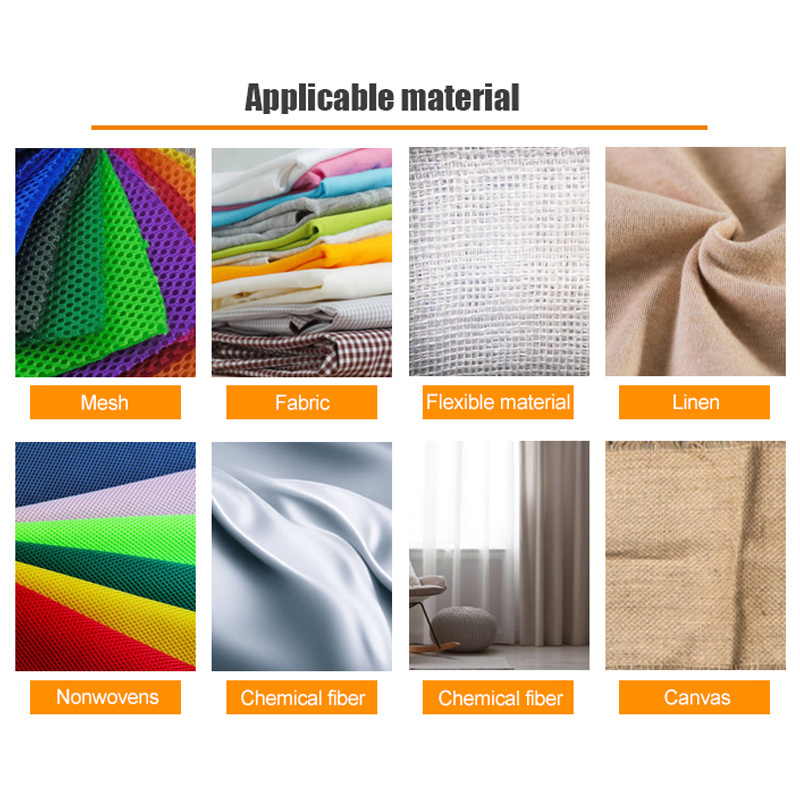

2. Versatility: These machines can handle a variety of fabric types from delicate silks to thick leathers, making them suitable for industries like fashion, automotive, or interior design.

3. High efficiency: With high-frequency oscillation, fabric cutting is fast and accurate, increasing productivity whether working with single or multiple fabric layers.

4. Reduced wear and tear: Rotating blades on fabric CNC cutting machines minimize fabric damage, maintaining structural integrity and reducing the need for extra finishing work.

5. Customization and flexibility: Equipped with CNC systems, these machines allow for automated cutting processes, offering customization options and quick adjustments between cutting tasks.

6. User-friendly: Easy to operate for both skilled and novice users, these machines have a short learning curve with proper

training, simplifying the use of complex cutting equipment.

2. Versatility: These machines can handle a variety of fabric types from delicate silks to thick leathers, making them suitable for industries like fashion, automotive, or interior design.

3. High efficiency: With high-frequency oscillation, fabric cutting is fast and accurate, increasing productivity whether working with single or multiple fabric layers.

4. Reduced wear and tear: Rotating blades on fabric CNC cutting machines minimize fabric damage, maintaining structural integrity and reducing the need for extra finishing work.

5. Customization and flexibility: Equipped with CNC systems, these machines allow for automated cutting processes, offering customization options and quick adjustments between cutting tasks.

6. User-friendly: Easy to operate for both skilled and novice users, these machines have a short learning curve with proper

training, simplifying the use of complex cutting equipment.

Garment Fabric CNC Vibrating Knife Cutting Machine:

Garment Fabric CNC vibrating knifeCutting Machine:

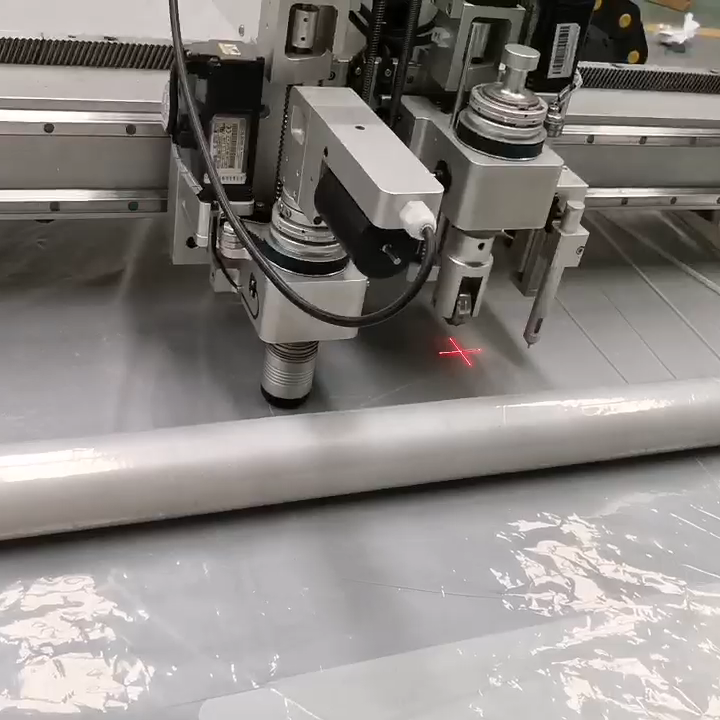

REALTOP Fabric cutting machines are designed to make precise, clean cuts in fabric, ensuring accuracy and reducing wear or damage to the material. The oscillating or rotating motion of the blade minimizes drag and provides a smooth, continuous cutting action for efficient cutting.

This type of fabric CNC cutting machine is often preferred for cutting complex shapes, patterns, or designs in fabrics due to its versatility and ability to handle different fabric types, thicknesses, and densities. It is commonly used in industries that require high quality and precise cutting

Product Parameters

|

Model

|

RT-D2516/RT-S2516

|

|

working area

|

1600*2500MM

|

|

Machine size

|

3450×2300×1250MM

|

|

Rated power

|

9kw

|

|

Fixed model

|

Flated working table

|

|

Multifunctional head

|

Swiss imported knife: with vibration full cutting, vibration half cutting and cursor location function.

|

|

Safety device

|

Using infrared sensors, responsive, safe and reliable.

|

|

translational velocity

|

800-1200mm/s

|

|

Cutting thickness

|

≤50mm(according to different cutting materials)

|

|

Cutting materials

|

Leather, all kinds of clothing flexible material, Sponge composite leather, PVC,

soft glass, Silicon, rubber |

|

Repeated accuracy

|

≤0.1mm

|

|

Transmission system

|

imported (Digital servo motor, linear guide, synchronous belt, ball screw)

|

|

Instruction system

|

HP-GL compatible format

|

|

Voltage

|

380V±10%

|

|

Other configuration

|

Delta servo motor, Germany imported conveyor belt, vacuum table, auto feeding, Taiwan Hiwin rail, 7.5kw vacuum pump

|

Product Details

Program the CNC Machine

* Upload the digital design file to the CNC machine’s control software.

* Configure the cutting parameters, such as cutting depth and speed, to match the fabric and thickness.

* Configure the cutting parameters, such as cutting depth and speed, to match the fabric and thickness.

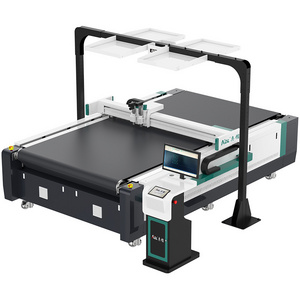

New modular tool holder design

*

Installing tools much more easier, when customers increase product categories, customers only need to buy new needed tools. Provide convenience for customers to upgrade products. Compatible tools: Round Knife, Marking Pen, Auto Feeder, ect..

* Start the CNC machine and initiate the cutting process. The machine will follow the programmed design, cutting the fabric with precision.

High precision aviation aluminum countertops

With the unique inner part of the wind structure, to ensure that each area of the platform suction even, more powerful suction.

Pinion and rack

The equipment adopts rack and pinion transmission compared with belt transmission, which has large bearing capacity, high transmission accuracy, fast transmission speed and long service life.

Distribution box

REALTOP CNC cutting machine fixes the control electrical box on the fuselage to avoid separation and cause line failure. All lines use high-flexibility cables, which have good wear resistance, moisture resistance, cold resistance and high temperature resistance.

Lathe bed structure

Overall welding process, imported milling machine processing, to ensure the smoothness of the guide rail surface and rack surface, greatly improve the stability of the machine running time body.

Table Cloth

High-density felt can offer great maintien for material ensure each positioning is tightly fitted and protect the flatbed while cutting.

Panasonic Servo motor

Stable performance, high precision, low failure rate, high speed performance.

Cutting Effect

Certifications

Our serve

1.

Pre-sales service——professional technical consultation

A. Free sample making For free sample making/testing, please send your samples or product CAD drawings to our company in China. Buy after testing.

B. Perfect solution design According to customers' product processing requirements, we can design unique solutions for customers, supporting higher manufacturing efficiency and better processing quality.

2.

After sales service - professional qualification and training

We will provide some parts for free for the first year. The buyer needs to pay for the shipping cost of the parts. Users need to send us the broken picture, then we will send the parts they need.

B. In the first year, if buyers need our engineers to come to the local area to solve machine problems that they cannot solve by themselves; we will send our engineers for free. The buyer needs to pay for the engineer's local air tickets, accommodation and meals.

C. If buyers need help with any technical issues, we will provide service by email and phone.

3.

Installation and technical training include

If necessary, we will send engineers to the customer's factory for local training and installation, which is free of charge. The buyer shall pay for the accommodation and meals of the local engineer.

Timely gold service, response to technical support within 24 hours, let you feel at ease.

4.

Customer-centric maintenance cost control guide

A. The supply of accessories is timely, we produce according to the order, more than 30 sets of accessories in stock, guarantee the order delivery and repair.

B. Relieve customers' worries about large equipment services; supply parts at bare cost.

5.

Sales service management system

Standardized service management system, including: customer contact management, customer troubleshooting management, regular maintenance of customer equipment, inspection management, customer file management and parts review, etc.

FAQ

1: What professional advice can you give me when I need to buy REALTOP digital cutting machine?

Please tell us what material you are cutting and the dimensions of the material (width and length). We will recommend a suitable model for you based on your material texture and size. If you can send us some trial cutting materials, we will record the cutting video for your reference, welcome to visit our company and factory if possible.

2: What materials can your machine cut?

REALTOP digital cutting machine can cut different kinds of soft materials. Used in different industries such as shoes, bags, clothing, cartons, composite materials, automobiles, and home furnishings.

3: How to use the machine? And what after-sales services can your company provide?

If you purchase our machine, we will provide free installation and training. We provide one year free warranty at home and abroad. We provide machine manual and software manual instructions for each machine, as well as videos for your reference and 24-hour online technical support. All this support is free until you are fluent in operating the machine.

4: What languages does the software system support?

The menu is available in English, Russian, Italian, Chinese, etc. Special languages can be customized.

5: How thick can your machine cut?

Our machine can choose different types of cutting tool heads according to the thickness of your different materials to achieve cutting of various materials with different thicknesses. The cutting thickness of the machine is ≤100mm (varies with the material).

6: This is my first time using this machine. Is it easy to operate?

We will send you English manual and instruction video, which can teach you how to operate the machine. If you're still having trouble learning how to use it, we can chat by phone, email, or other contact method. Problems caused by incorrect operation will also be well solved.

7: Can the machine be customized according to my requirements?

Of course, we have a strong technical team and rich experi

Hot Searches