- Product Details

- {{item.text}}

Quick Details

-

Size(cm):

-

750 x 650 x750

-

weight:

-

85kg

-

matching accuracy:

-

±1%

-

glue dispensing accuracy:

-

±1%

-

motor system:

-

hybrid servo motor

-

A/B raw material pail:

-

304 stainless steel

-

operation mode:

-

point movement and quantitative analysis

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

A/B epoxy resin, polyurethan etc.

-

operation system:

-

PLC+touch screen

-

Size(cm):

-

750 x 650 x750

-

weight:

-

85kg

-

matching accuracy:

-

±1%

-

glue dispensing accuracy:

-

±1%

-

motor system:

-

hybrid servo motor

-

A/B raw material pail:

-

304 stainless steel

-

operation mode:

-

point movement and quantitative analysis

AB High Precision Glue Dispensing Machine

Product Description

|

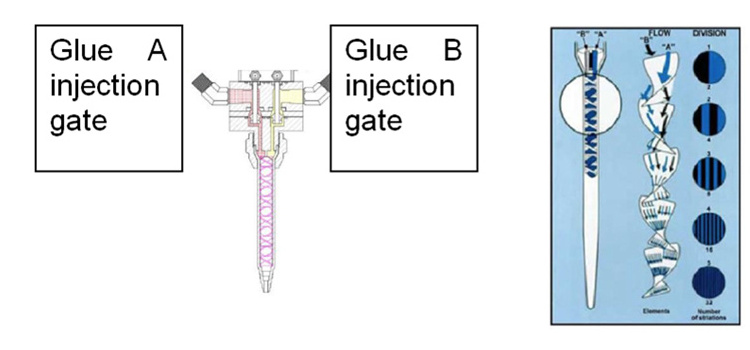

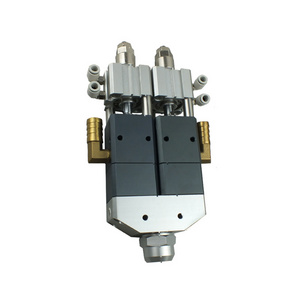

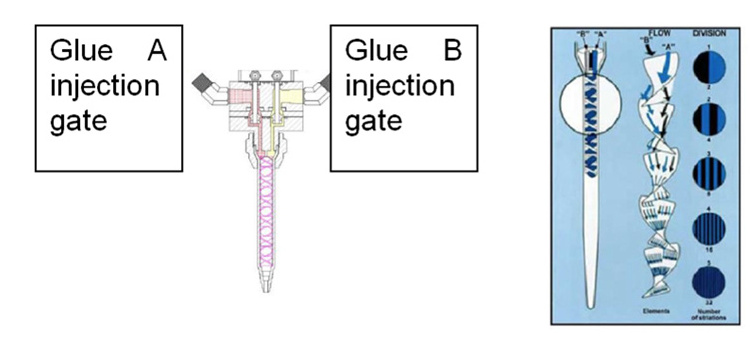

1. American MAC double air valve control and valve core balance design,

suitable for two-component fluid mixer. |

| 2.Good suction function to ensure quick and clean. |

|

3.The A / B component was transported separately before mixing,

avoiding the possibility of mixing during the transportation process. |

|

4.In the process of mixing a single element through a mixing tube, the A /

B component fluid uses the fluid to split, shear, rotate, and converge several times to achieve full mixing effect. |

|

5.The mixed head outlet adopts the standard interface of "TAH" mixing

pipe, which ensures the reliability of installation. |

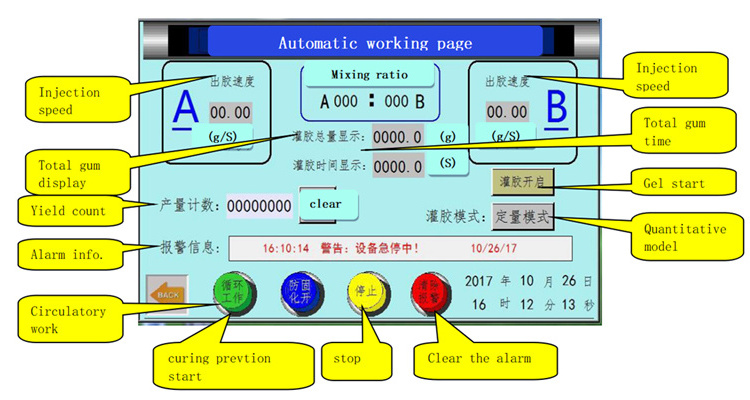

| Control method: | MITSUBISHI PLC control + nylon touch screen |

| Measurement method: |

A component gear metering pump /B component gear

metering pump |

| Hybrid mode: | Static mixing |

| Scope of dispensing: | 1g/sec~5g/sec |

| Proportional precision: |

≤±1%(Taking 5 seconds glue injection time as the

benchmark) |

| Accuracy of dispensing: |

≤±1%(Taking 5 seconds glue injection time as the

benchmark) |

|

Single minimum amount of

gum leakage: |

≥ 1 second injection time |

| Ratio: |

The ratio of 1:1 to 10:1 can be achieved by configuring different

metering pumps and mixing heads |

| Suitable for viscosity range: | 1~20 000mPa.s |

| Operation mode: | quantitative / automatic / continuous |

| Product technical parameters | |

| 1. Specification type: | WD—T050G |

| 2. Motor system: | Hybrid servo motor |

| 3. Operation mode: | Point movement and quantitative analysis. |

| 4. Applicable viscosity | :200~20000CPS. |

| 5. Matching accuracy: |

±1% (Taking 5 seconds glue injection time as the benchmark). |

| 6. Glue dispensing accuracy: |

±1% (Taking 5 seconds glue injection time as the benchmark). |

| 7. Mixing ratio: | 100:100 |

| 8. glue dispensing speed: | 1g/sec~5g/sec |

| 9. Operation system: | PLC+touch screen. |

| 10. Feeding mode: | Manual. |

| 11. Metering mode: |

Precision gear pump / screw pump (according to the formula of glue). |

| 12. Operation mode: | Foot switch / start switch / online communication control |

| 13. Anti setting: | 0-9999Sec |

| 14. Size(cm): | 750 x 650 x750 |

| 15.Body weight: | 85g |

| 16.Related technical requirements |

a) Ambient temperature 20℃~45℃,relative humidity≤80% working

on the condition |

| b) Power:AC220V/50Hz/ 3.5KW | |

|

c) Gas source specification: ≥0.4~0.6Mpa, The gas source is stable and the error is not more than + 0.1 |

|

Packaing&Shiping

Hot Searches