- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinhui

-

Model Number:

-

545

-

Type:

-

Liquid Glue

-

Color:

-

purple

-

Viscosity:

-

14000 mPa.s

-

Sealing presure:

-

69 MPa

-

Temperature:

-

-54~149

-

Fixture time/Full cure time:

-

30 min / 24 h

Quick Details

-

CAS No.:

-

mixture

-

Other Names:

-

pipe sealant

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinhui

-

Model Number:

-

545

-

Type:

-

Liquid Glue

-

Color:

-

purple

-

Viscosity:

-

14000 mPa.s

-

Sealing presure:

-

69 MPa

-

Temperature:

-

-54~149

-

Fixture time/Full cure time:

-

30 min / 24 h

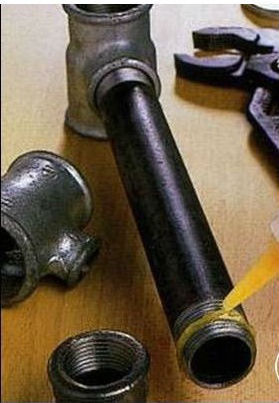

Anaerobic Thread Locking sealant 545 Fast curing Piping thread sealant

Anaerobic Thread Locking sealant 545

1, Fast cure, low strength.

2, No pollution to hydraulic pipe system,

3, Can be appliedon surfaces with light oil.

4, Contains no fillers and will not foul valves or fluidfiltering systems

Product description

|

Appearance (uncured) |

Purple liquid |

|

Chemical Type |

Methacrylate Ester |

|

Components |

One component |

|

Strength |

Low |

|

Viscosity |

Medium |

|

Cure |

Anaerobic |

|

Application |

Pipe threading sealing |

Typical application

JH545 is designed for the locking and sealing of metal pipes and fittings in pneumatic/hydraulic system. No pollution for hydraulic system. It cures when confined in the absence of air between close fitting metal surfaces and prevents loosening and leakage from shock and vibration. This product is specially formulated to offer lubricity for easy assembly. It is also oil resistance.

Typical properties of uncured material

|

Gravity @25°C |

1.02 |

|

Viscosity, 25°C, mPa•s (cP): |

9,000 to 20,000 |

|

Flash point |

>93°C |

|

Cure speed |

Fixture cure time 40 minutes, full cure time is 24 hours |

Typical properties of cured material (M10 steel nut and bolt, @22 °C, after 24hr full cured)

|

Temperature (°C) |

-50 —150 |

|

Type of tension |

The maximum sealing tension is 69Mpa. |

|

Breakaway Torque ISO-10964 (N.m) |

2 — 3 |

|

Breakloose Torque ISO-10964 (N.m) |

2 — 3 |

|

Coefficient of Thermal Expansion, ASTM D 696, K -1 |

80*10 -6 |

|

Coefficient of Thermal Conductivity, ASTM C 177, W/(m•K) |

0.10 |