EXTENDING UNDERCARRIAGE

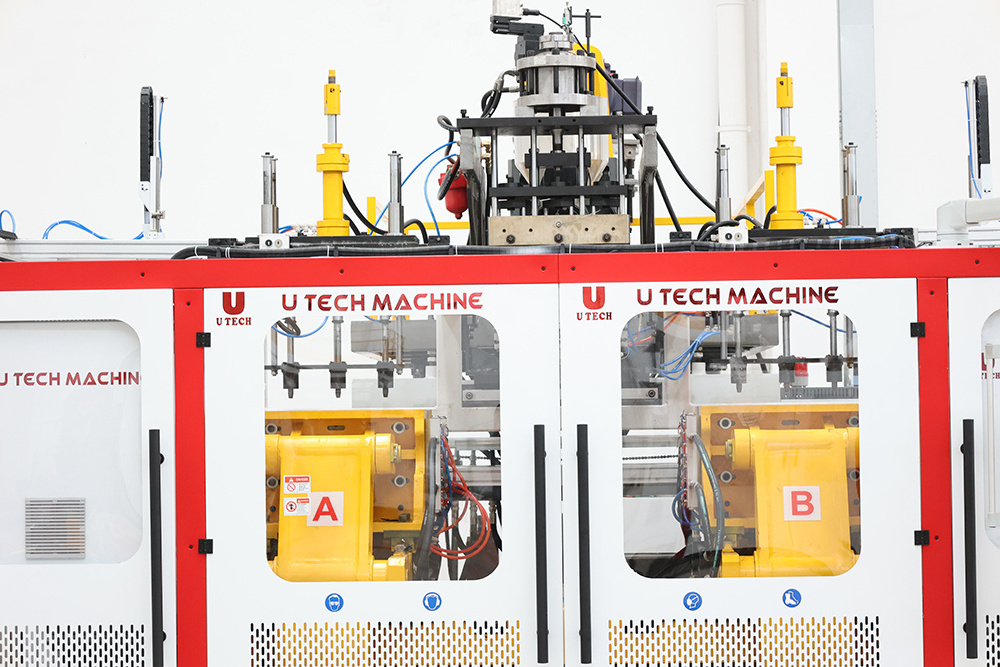

SAFETY FRAME

SIMPLE CONTROL

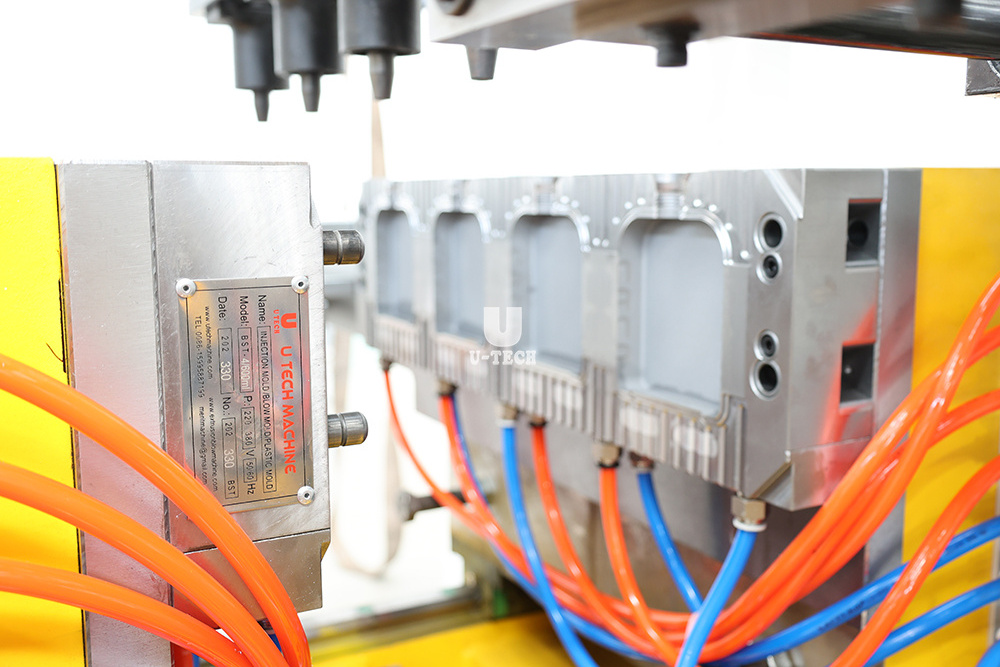

SEASY MAINTENANCE

VERSATILITY

EXTENDING UNDERCARRIAGE