- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

(D)1.6m*2.5m

-

Voltage:

-

220V-10KV

-

Power:

-

15000

-

Weight (KG):

-

5000

-

Product Name:

-

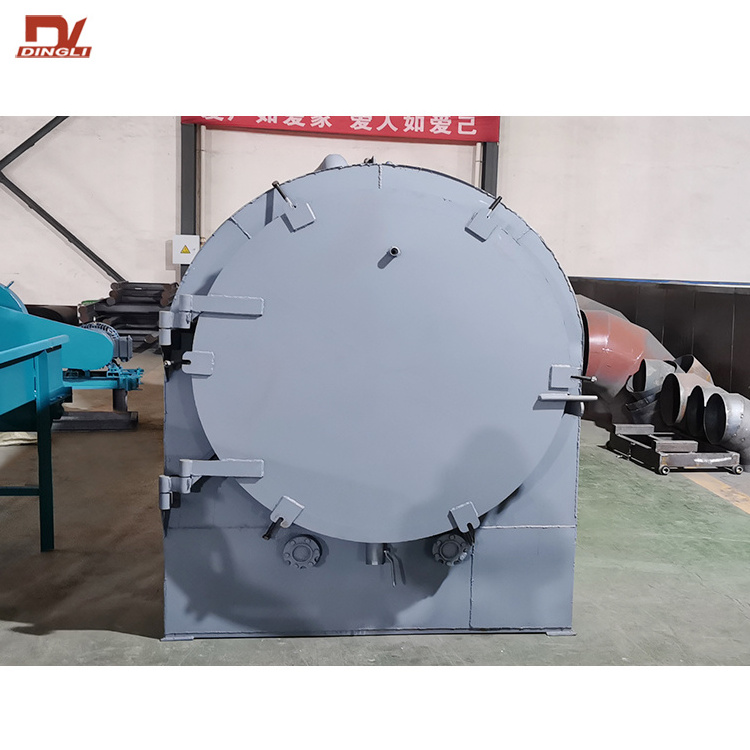

Horizontal Airflow Hard Wood Carbonization Furnace

-

Color:

-

Silver Or Customized

-

Material:

-

Carbon steel, refractory

-

Capacity:

-

4m*m*m

-

Inner Tank Diameter(m):

-

1.6

-

Inner Tank Length(m):

-

2.5

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

With carbonized color display

-

Raw Material:

-

Coconut Shell, Log, Wood Stick, Jute Stick, Bamboo, Wood Branches

-

Usage:

-

Agricultural and forestry biomass charring making

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DINGLI

-

Effective Volume:

-

Customized

-

Dimension(L*W*H):

-

(D)1.6m*2.5m

-

Voltage:

-

220V-10KV

-

Power:

-

15000

-

Weight (KG):

-

5000

-

Product Name:

-

Horizontal Airflow Hard Wood Carbonization Furnace

-

Color:

-

Silver Or Customized

-

Material:

-

Carbon steel, refractory

-

Capacity:

-

4m*m*m

-

Inner Tank Diameter(m):

-

1.6

-

Inner Tank Length(m):

-

2.5

-

Equipped With:

-

Cooling discharging machine

-

Production Status:

-

With carbonized color display

-

Raw Material:

-

Coconut Shell, Log, Wood Stick, Jute Stick, Bamboo, Wood Branches

-

Usage:

-

Agricultural and forestry biomass charring making

Product Introduction

Dingli horizontal dry distillation carbonization furnace is special used for log, wood, jute stick and other long rod-type biomass characteristics, adopts horizontal structure, cart entry and exit raw material and the advanced hot gas dry carbonization process technology, using a unique carbonization flue gas (volatile hydrogen material and tar, etc.) Back Burning Technology, make full use of the flue gas produced by carbonization process, meet the thermal needs of carbonization furnace itself, greatly increase the carbonization rate, the carbonization rate increased from 80% to more than 95%, and easy to operate, safety and environmental protection, high production efficiency, can save a lot of energy, is the ideal equipment for carbonizing the long rod type biomass material. Combination mode of multiple devices, use carbonized flue gas in tandem, can reduce fuel consumption during carbonization production and improve the enterprise benefit.

Below is Carbonizing Process

Dingli horizontal biomass dry distillation carbonization furnace consists of inner tank, insulation, furnace door, rail car , combustible gas reburning pipe, dehumidifying buffer tank, burner, exhaust pipe, and thermometer. The gasifier and flue gas purification device are the optional machine. This furnace using anaerobic dry distillation principle to remove volatile substances in biomass material, to carbonize the biomass material, carbonization process: Feeding raw material and sealing the furnace→Preheating and drying the raw material → Anaerobic carbonization →Cooling and discharging the carbon, total four steps.

|

Model

|

Capacity(m³)

/carbonization process time |

Length (m)

|

Width (m)

|

Internal

length (m) |

Internal

diameter (m) |

Material

|

|

DLWT300

|

1.2/6h

|

1.9

|

1.15

|

1.7

|

0.95

|

|

|

DLWT700

|

3/7h

|

1.9

|

1.7

|

1.7

|

1.5

|

|

|

DLWT1000

|

4.76/7h

|

2.9

|

1.7

|

2.7

|

1.5

|

|

|

DLWT1600

|

7.65/9h

|

2.9

|

2.2

|

2.7

|

1.9

|

|

|

DLWT2000

|

10.48/10h

|

3.9

|

2.2

|

3.7

|

1.9

|

|

|

DLWT3100

|

15.86/12h

|

5.8

|

2.2

|

5.6

|

1.9

|

|

Below is Working Principle

Feeding raw material and sealing the furnace: use the rail car to feed the raw material into the carbonization furnace and lock the furnace door, finaly sealing the furnace. Preheating and drying the raw material: use the wood or other fuel heat the raw material inside the furnace, from room temperature slowly heat up to 220-250℃, this process time is about 1.2 to 2.0 hours (the specific heating-up time is mainly depend on raw material moisture content, density, diameter size,etc), discharge water inside the raw material and the air in the inner tank. Anaerobic carbonization: When the temperature inside the carbonization furnace increase to there is little yellow smoke discharged from the smoke tube ( hydrogen,oxygen and other volatile substances). it means start the carbonization process, then we can recovery of combustible flue gas into furnace ignition, Adjust the intake combustible flue gas amount, keep the temperature in the inner tank about 300-550℃, 2.0-3.5 hours (the specific temperature and carbonization time is mainly depend on raw material moisture content, density, diameter size and carbonization degree,etc). When it stops burning naturally inside the furnace, the carbonization is finished. Cooling and discharging the carbon: when the carbonization is finished, we need to open the cooling water valve to cool the inner tank, when the temperature inside of the inner tank reduce to below 50℃, then we can open the furnace door and discharging the carbon. The heating-up time and carbonization time of this model carbonization furnace is total about 5.5-9.5 hours, so it can finish 3 batches every 24 hours. The exhaust gas is discharged through the dust collector and can meet the environmental protection requirement. 3-5 sets of carbonization furnace used in parallel, peak shifting carbonization process. it can maximize use the combustible flue gas heating carbonization furnace each other, reduce the fuel consumption.