(Optional configuration):Hydraulic decoiler

Capacity:Max.5 Ton\8 Ton\10 Ton\15 Ton or as requirement;

Hydraulic system expand coil inner hole,

Frequency Inverter to regulate turning speed

Link-connect expanding system

Coil Inner-diameter=510±30 mm, Coil width = Max.1250mm or 1650mm;

Automatic stopping device with limited switch as assistance to control stop/start rotation

- Product Details

- {{item.text}}

Quick Details

-

Coil Weight (T):

-

20T

-

Leveling Precision(±mm/m):

-

0.2 ±mm/m

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

ZHENGLIMING

-

Voltage:

-

380v Or customized

-

Weight:

-

7000

-

Product name:

-

coils sllitting machine line

-

Raw material:

-

Steel Coil GI PPGI

-

Keyword:

-

full automatic

-

Coil width:

-

100-1250mm

-

Material:

-

SS,AL,AL-Alloy, CS steel

-

Function:

-

Cutting Coils

-

Coil thickness:

-

0.1-8mm

-

Control system:

-

Full control by PLC touch screen & button

Quick Details

-

Cutting Width (mm):

-

20 - 1850 mm

-

Material Thickness(mm):

-

1 - 8 mm

-

Cutting Speed(m/min):

-

20 - 100 m/min

-

Coil Weight (T):

-

20T

-

Leveling Precision(±mm/m):

-

0.2 ±mm/m

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

ZHENGLIMING

-

Voltage:

-

380v Or customized

-

Weight:

-

7000

-

Product name:

-

coils sllitting machine line

-

Raw material:

-

Steel Coil GI PPGI

-

Keyword:

-

full automatic

-

Coil width:

-

100-1250mm

-

Material:

-

SS,AL,AL-Alloy, CS steel

-

Function:

-

Cutting Coils

-

Coil thickness:

-

0.1-8mm

-

Control system:

-

Full control by PLC touch screen & button

Product Description

Competitive price automatic security slitting line steel coil slitting machine

1. This machine adopts PLC control, easy to operate, reliable performance and beautiful appearance. Set the parameters on the PLC control cabinet, the machine automatically leveling and cutting, easy to operate and save labor cost. The leveling and shearing machine cuts metal plates at fixed lengths according to customer requirements. Set the length on the Plc, and the calibrating and shearing machine cuts automatically, saving labor cost.

2. Maintain the sheet flat feed, the surface of the sheared sheet is smooth without scratches, the cut is flat, no falling material, saving material cost.

3. The slitting roller adopts Cr12Mov, heat treatment, durable material, smooth cut of the slitted sheet.

4. The laminating device can be added according to customers' requirements With push-pull grid guard above the main machine to protect the safety of employees.

Packing list

|

Decoiler

|

1 set

|

|

Shearing and slitting machine

|

1 set

|

|

Automatic conveyor

|

1 set

|

|

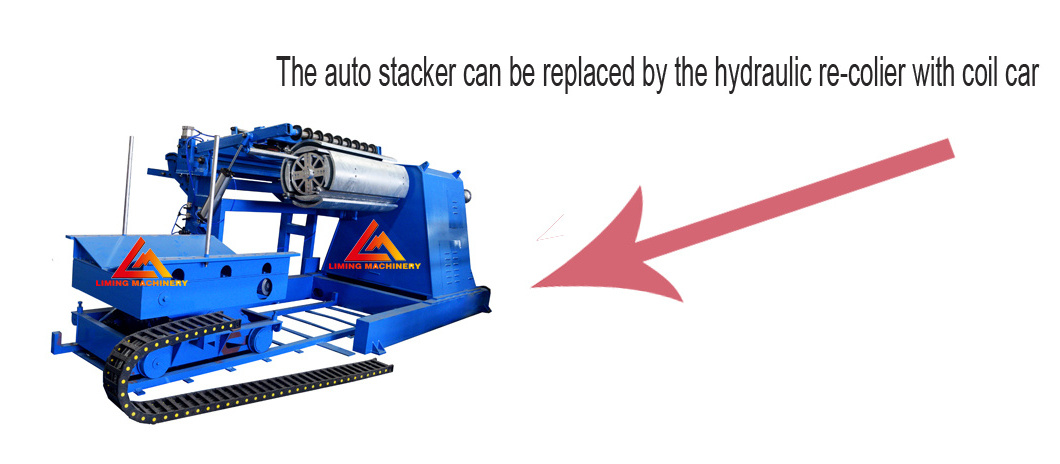

Stacker/Recoiling Line

|

1 set

|

|

Hydraulic oil pump station

|

1 set

|

|

PLC control system

|

1 set

|

Profile Details

Hydraulic Decoiler(Seltectable):one set

Forming station:

Simple Straightening, slitting and shearing machine

Bbody frame made from H450 type steel by welding

Feeding Section with guide device

Rollers manufactured from Cr12 steel,CNC lathes,Heat Treatment,hard Chrome Coated

The warranty for the rollers is 1 years

Real forming speed 20m/min (depending on the number of punching holes)With squareness roller setup

Protection Mesh Cover Above Roll-former To Avoid Hands Go Inside

Bbody frame made from H450 type steel by welding

Feeding Section with guide device

Rollers manufactured from Cr12 steel,CNC lathes,Heat Treatment,hard Chrome Coated

The warranty for the rollers is 1 years

Real forming speed 20m/min (depending on the number of punching holes)With squareness roller setup

Protection Mesh Cover Above Roll-former To Avoid Hands Go Inside

Product Paramenters

|

1.5Ton*1250mm Hydraulic un-coiler

|

|

||

|

Description

|

There are different choices

|

||

|

2. Straightening, slitting and shearing machine

|

|

||

|

Polythene Film-On device, un-powered

|

|

||

|

Straightening Device with 5 over 4 shafts to remove the Coil-set

|

|

||

|

Straightening& slitting motor:

|

11KW

|

||

|

Electric guillotine:

|

Main Motor=5.5KW

|

||

|

Working width:

|

MAX.1650mm

|

||

|

Work thickness

|

0.2-2.5mm

|

||

|

Protection Mesh Cover Above Roll-former To Avoid Hands Go Inside

|

|

||

|

3. PLC control system

|

|

||

|

PLC

|

Siemens brand (ABB brand is available if required)

|

||

|

Touch Screen

|

Siemens brand (ABB brand is available if required)

|

||

|

Inverter

|

Schneider brand (ABB brand is available if required)

|

||

|

Encoder

|

Omron brand

|

||

|

4.Product rack

|

|

||

|

Description(optional)

|

un-powered, 2 meters, 2 units

Reciling Line Auto Stacker |

||

|

5. Serviceafter sell

|

|

||

|

In correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric

elements. Installation: (1) If installation is needed, Liming (the seller) will dispatch technician to the buyer's factory abroad to assist regulating the machine with charge free. The buyer should assist Liming to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation. (2) If installation is needed, the buyer shall make the following preparation before arrival of technicians. a) Position the machine in the buyer's factory. b) Prepare necessary electric wiring. c) Prepare material of trial running. d) Provide labors for assistance and installation during installation. e) If possible, One Chinese-speaking interpreter so that the communication between the buyer and seller's technician will go smoothly. |

|

||

|

6.Terms Of Trade

|

|

||

|

Package & Shipment: Facility water-proof packing, Control cabinet packed in wooden packing.

Payment: 30%payment by T/T is required as deposit within a week since the contract signing date.70% payment by T/T is required before the machine be send out of factory. |

|

||

|

|

|

||

FAQ

1. Are you a factory?

2. How about the strength of your factory?

Our factory was founded in Xiamen in 1989, covering an area of more than 100,000 square meters. We are a national high-tech enterprise, a national standard maker, a municipal-level enterprise technology center, with 18 invention patents, 77 utility model patents and 1 appearance design patent.

4. How do you guarantee that you can make the machine as order?

We have industry-leading technicians, professional teams. We focus on the combination of production, R&D, and studying. We also cooperate with universities and specialize in difficult and feasible solutions for the industry. We have nearly 100 R&D people and production staff to produce light-structured and reasonably designed machines in time to meet our customers' needs.

5. How does your factory do regarding quality control?

Quality is priority. First of all, we have in-house laboratory and scientific quality control department. Secondly, we have 146 sets of high-end professional production equipments, multiple process quality inspection to ensure product quality. Most importantly, Zheng Liming always attach great importance to quality control from the very beginning to the end of the entire production. Every roll forming machine will be fully assembled and carefully tested before it's packed for shipment.

6.Do you sell only standard machines?

No, most of our roll forming machines are built according to customers specifications, using top brand components.

7. How can I visit your factory?

Our address is 187#, No. 2 Zhen Nan Road, Tong’an District, Xiamen, China. We sincerely welcome you to visit our factory!

Yes, we are a factory. Xiamen Zheng Liming Metallurgical Machinery Co., Ltd, founded in 1989, has been in business for more than 30 years and covers an area of more than 100,000 square meters. It is the first manufacturer specializing in the manufacturing industry of various cold rolling mills/ roll forming lines in China.

2. How about the strength of your factory?

Our factory was founded in Xiamen in 1989, covering an area of more than 100,000 square meters. We are a national high-tech enterprise, a national standard maker, a municipal-level enterprise technology center, with 18 invention patents, 77 utility model patents and 1 appearance design patent.

3. Do you have after-sales support?

We will provide technical support for the whole life cycle of the machine. And we also have skilled technicians available on hand. If you need, we can send our technicians to train your staff.

We will provide technical support for the whole life cycle of the machine. And we also have skilled technicians available on hand. If you need, we can send our technicians to train your staff.

4. How do you guarantee that you can make the machine as order?

We have industry-leading technicians, professional teams. We focus on the combination of production, R&D, and studying. We also cooperate with universities and specialize in difficult and feasible solutions for the industry. We have nearly 100 R&D people and production staff to produce light-structured and reasonably designed machines in time to meet our customers' needs.

5. How does your factory do regarding quality control?

Quality is priority. First of all, we have in-house laboratory and scientific quality control department. Secondly, we have 146 sets of high-end professional production equipments, multiple process quality inspection to ensure product quality. Most importantly, Zheng Liming always attach great importance to quality control from the very beginning to the end of the entire production. Every roll forming machine will be fully assembled and carefully tested before it's packed for shipment.

6.Do you sell only standard machines?

No, most of our roll forming machines are built according to customers specifications, using top brand components.

7. How can I visit your factory?

Our address is 187#, No. 2 Zhen Nan Road, Tong’an District, Xiamen, China. We sincerely welcome you to visit our factory!

Hot Searches