- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-160-380

-

Size:

-

Customized Magnet Size

-

Certification:

-

Rohs, MSDS

-

Material:

-

NdFeB magnet

-

MOQ:

-

1set

-

Product Name:

-

Powder Magnetic Separator

-

Sample:

-

Available

-

Advantage:

-

High Performance

-

Package:

-

Customized

-

Usage:

-

Industrial Magnet, Industrial Magnet, Food, Medical

-

Feature:

-

Durable

Quick Details

-

Tolerance:

-

±5%

-

Grade:

-

SUS304 316L Stainless Steel

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-160-380

-

Size:

-

Customized Magnet Size

-

Certification:

-

Rohs, MSDS

-

Material:

-

NdFeB magnet

-

MOQ:

-

1set

-

Product Name:

-

Powder Magnetic Separator

-

Sample:

-

Available

-

Advantage:

-

High Performance

-

Package:

-

Customized

-

Usage:

-

Industrial Magnet, Industrial Magnet, Food, Medical

-

Feature:

-

Durable

Specification

Support all Shape magnets ,

as long as you tell us the size or drawing you need, we can produce it!

Product overview

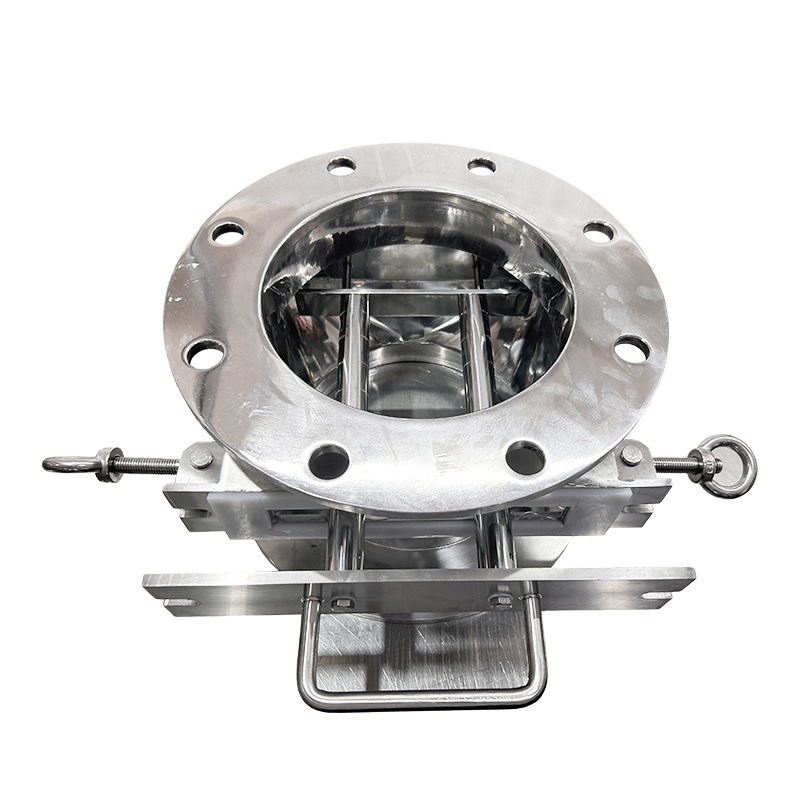

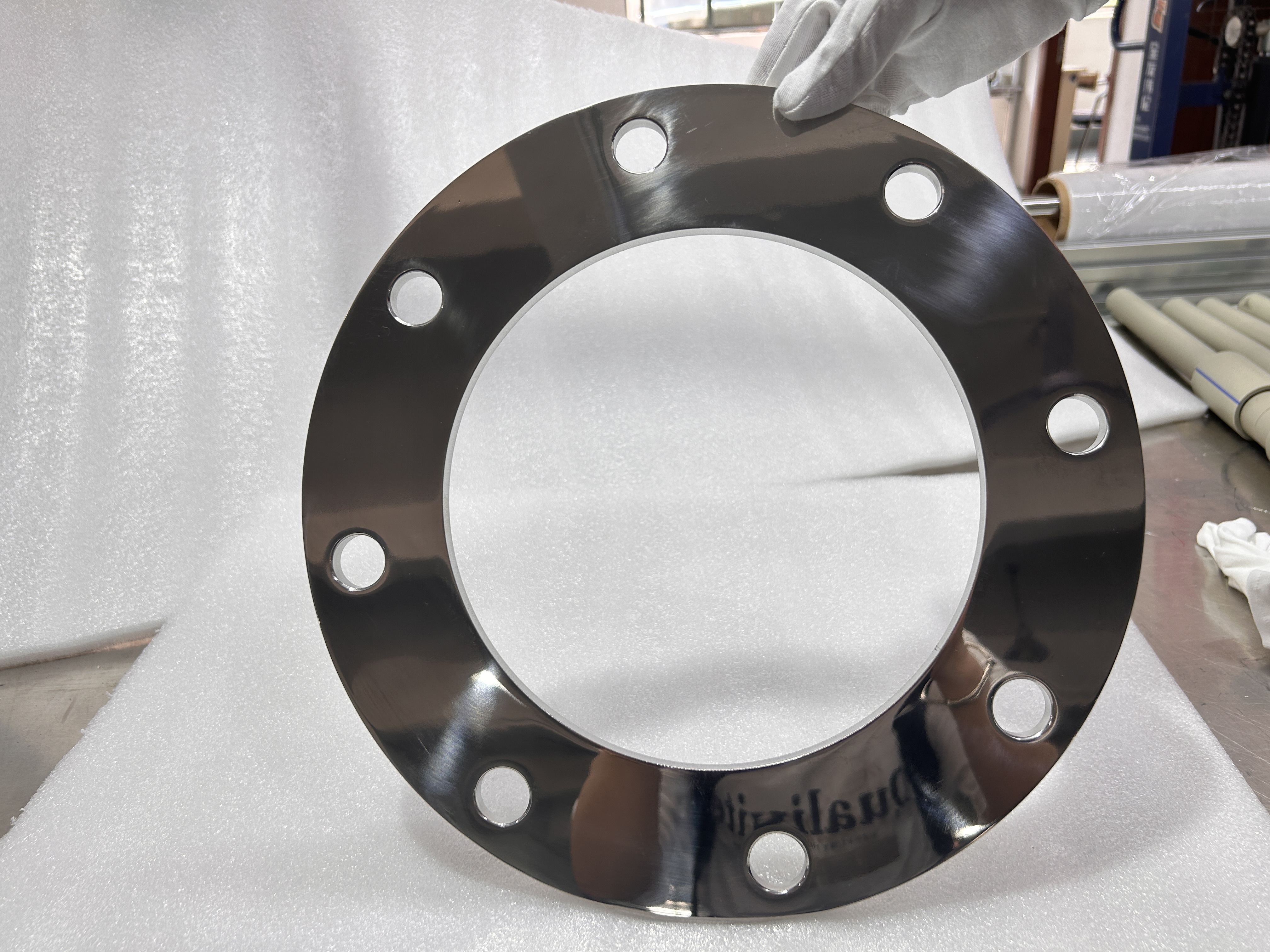

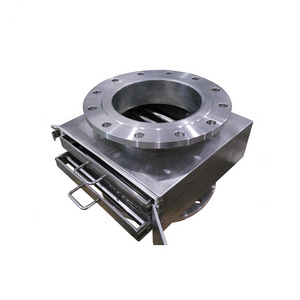

Magnetic Liquid Traps or Magnetic Liquid Filters are designed for liquid or semi-liquid flow systems to remove ferrous contamination from liquid with different viscosity level.

They preserve product purity by removing small contaminants,provide magnetic protection for liquid lines and processing equipments. Magnetic Bars containing high intensity rare earth neodymium iron boron magnets are housed within a 304 stainless steel vessel.

Magnetic configuration ensures maximum exposure of contamination to the high intensity tubes without impeding liquid flow.

The product can work up to 80° C (176° F).

If temperature resistance is required, we can optimize the design to work up to 350° C (662° F).

Our Service:

1. We will offer the suitable iron separator project according your material and working environment for your reference.

2. We can do the test to confirm the iron separation effect for free.

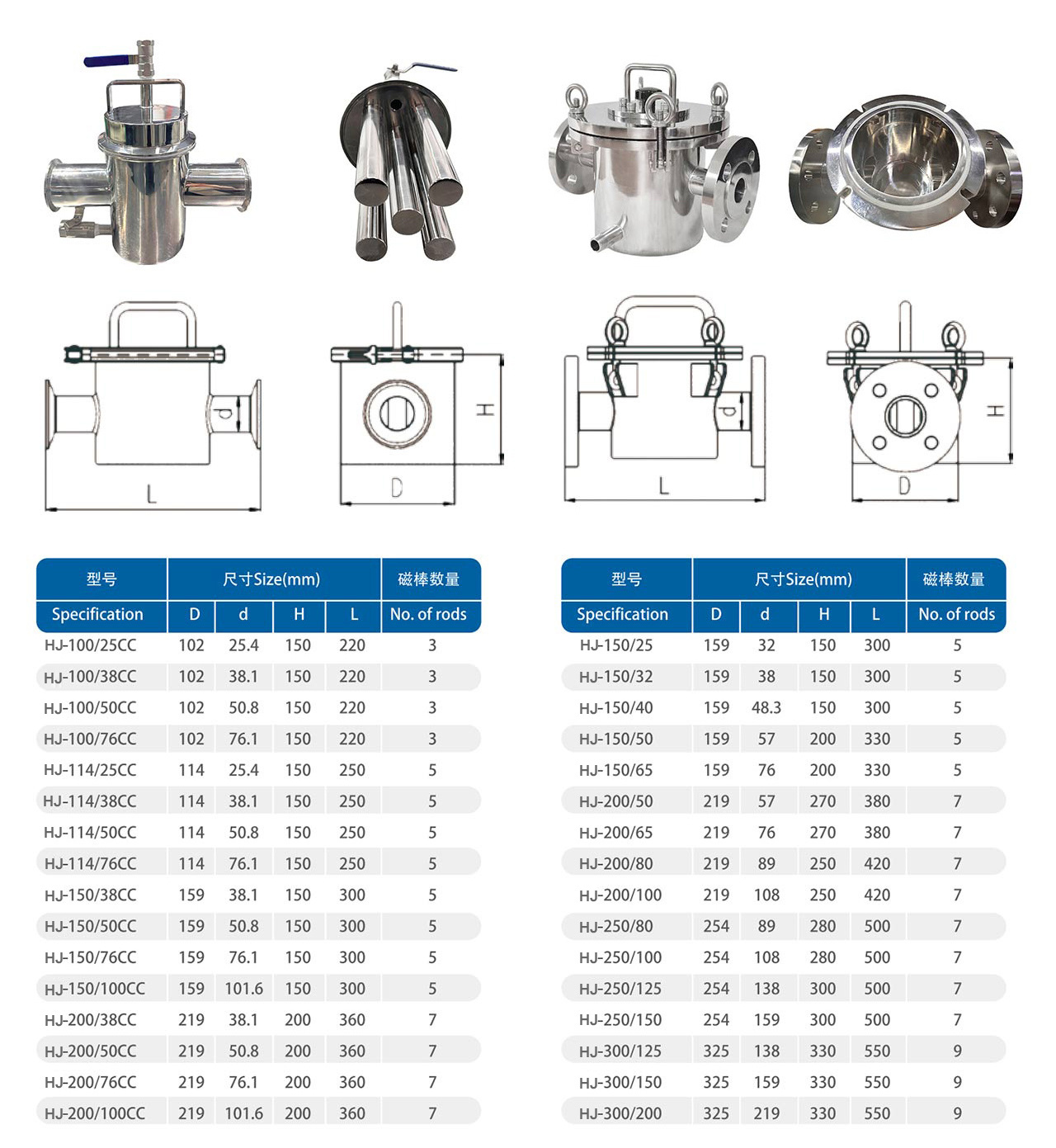

Technical Parameters:

Note: 1. Special sizes available upon request.

2. Dimensions and specifications are subject to change without notice.

Product Details

More products

Product Parameters

|

Grade

|

Remanence

|

|

Coercivity Force

|

|

Intrinsic Coercive Force

|

|

Max. Energy Product

|

|

Working Temp

|

||||

|

|

Br

|

|

Hcb

|

|

Hcj

|

|

(BH)max

|

|

|

||||

|

|

mT

|

kGs

|

kA/m

|

kOe

|

kA/m

|

kOe

|

kJ/m3

|

MGOe

|

|

||||

|

N35

|

1170-1220

|

11.7-12.2

|

≥ 868

|

≥ 10.9

|

≥ 955

|

≥ 12

|

263-287

|

33-36

|

80 ° C

|

||||

|

N38

|

1220-1250

|

12.2-12.5

|

≥ 899

|

≥ 11.3

|

≥ 955

|

≥ 12

|

287-310

|

36-39

|

80 ° C

|

||||

|

N40

|

1250-1280

|

12.5-12.8

|

≥ 907

|

≥ 11.4

|

≥ 955

|

≥ 12

|

302-326

|

38-41

|

80 ° C

|

||||

|

N42

|

1280-1320

|

12.8-13.2

|

≥ 915

|

≥ 11.5

|

≥ 955

|

≥ 12

|

318-342

|

40-43

|

80 ° C

|

||||

|

N45

|

1320-1380

|

13.2-13.8

|

≥ 923

|

≥ 11.6

|

≥ 955

|

≥ 12

|

342-366

|

43-46

|

80 ° C

|

||||

|

N48

|

1380-1420

|

13.8-14.2

|

≥ 923

|

≥ 11.6

|

≥ 876

|

≥ 12

|

366-390

|

46-49

|

80 ° C

|

||||

|

N50

|

1400-1450

|

14.0-14.5

|

≥ 796

|

≥ 10.0

|

≥ 876

|

≥ 11

|

382-406

|

48-51

|

60 ° C

|

||||

|

N52

|

1430-1480

|

14.3-14.8

|

≥ 796

|

≥ 10.0

|

≥ 876

|

≥ 11

|

398-422

|

50-53

|

60 ° C

|

||||

|

35M

|

1170-1220

|

11.7-12.2

|

≥ 868

|

≥ 10.9

|

≥ 1114

|

≥ 14

|

263-287

|

33-36

|

100 ° C

|

||||

|

38M

|

1220-1250

|

12.2-12.5

|

≥ 899

|

≥ 11.3

|

≥ 1114

|

≥ 14

|

287-310

|

36-39

|

100 ° C

|

||||

|

40M

|

1250-1280

|

12.5-12.8

|

≥ 923

|

≥ 11.6

|

≥ 1114

|

≥ 14

|

302-326

|

38-41

|

100 ° C

|

||||

|

42M

|

1280-1320

|

12.8-13.2

|

≥ 955

|

≥ 12.0

|

≥ 1114

|

≥ 14

|

318-342

|

40-43

|

100 ° C

|

||||

|

45M

|

1320-1380

|

13.2-13.8

|

≥ 995

|

≥ 12.5

|

≥ 1114

|

≥ 14

|

342-366

|

43-46

|

100 ° C

|

||||

|

48M

|

1360-1430

|

13.6-14.3

|

≥ 1027

|

≥ 12.9

|

≥ 1114

|

≥ 14

|

366-390

|

46-49

|

100 ° C

|

||||

|

50M

|

1400-1450

|

14.0-14.5

|

≥ 1033

|

≥ 13.0

|

≥ 1114

|

≥ 14

|

382-406

|

48-51

|

100 ° C

|

||||

|

35H

|

1170-1220

|

11.7-12.2

|

≥ 868

|

≥ 10.9

|

≥ 1353

|

≥ 17

|

263-287

|

33-36

|

120 ° C

|

||||

|

38H

|

1220-1250

|

12.2-12.5

|

≥ 899

|

≥ 11.3

|

≥ 1353

|

≥ 17

|

287-310

|

36-39

|

120 ° C

|

||||

|

40H

|

1250-1280

|

12.5-12.8

|

≥ 923

|

≥ 11.6

|

≥ 1353

|

≥ 17

|

302-326

|

38-41

|

120 ° C

|

||||

|

42H

|

1280-1320

|

12.8-13.2

|

≥ 955

|

≥ 12.0

|

≥ 1353

|

≥ 17

|

318-342

|

40-43

|

120 ° C

|

||||

|

45H

|

1300-1360

|

13-13.6

|

≥ 963

|

≥ 12.1

|

≥ 1353

|

≥ 17

|

326-358

|

43-46

|

120 ° C

|

||||

|

48H

|

1370-1430

|

13.7-14.3

|

≥ 995

|

≥ 12.5

|

≥ 1353

|

≥ 17

|

366-390

|

46-49

|

120 ° C

|

||||

|

33SH

|

1130-1170

|

11.3-11.7

|

≥ 844

|

≥ 10.6

|

≥ 1592

|

≥ 20

|

247-271

|

31-34

|

150 ° C

|

||||

|

35SH

|

1170-1220

|

11.7-12.2

|

≥ 876

|

≥ 11.0

|

≥ 1592

|

≥ 20

|

263-287

|

33-36

|

150 ° C

|

||||

|

38SH

|

1220-1250

|

12.2-12.5

|

≥ 907

|

≥ 11.4

|

≥ 1592

|

≥ 20

|

287-310

|

36-39

|

150 ° C

|

||||

|

40SH

|

1240-1280

|

12.5-12.8

|

≥ 939

|

≥ 11.8

|

≥ 1592

|

≥ 20

|

302-326

|

38-41

|

150 ° C

|

||||

|

42SH

|

1280-1320

|

12.8-13.2

|

≥ 987

|

≥ 12.4

|

≥ 1592

|

≥ 20

|

318-342

|

40-43

|

150 ° C

|

||||

|

45SH

|

1320-1380

|

13.2-13.8

|

≥ 1003

|

≥ 12.6

|

≥ 1592

|

≥ 20

|

342-366

|

43-46

|

150 ° C

|

||||

|

30UH

|

1080-1130

|

10.8-11.3

|

≥ 812

|

≥ 10.2

|

≥ 1990

|

≥ 25

|

223-247

|

28-31

|

180 ° C

|

||||

|

33UH

|

1130-1170

|

11.3-11.7

|

≥ 852

|

≥ 10.7

|

≥ 1990

|

≥ 25

|

247-271

|

31-34

|

180 ° C

|

||||

|

35UH

|

1180-1220

|

11.8-12.2

|

≥ 860

|

≥ 10.8

|

≥ 1990

|

≥ 25

|

263-287

|

33-36

|

180 ° C

|

||||

|

38UH

|

1220-1250

|

12.2-12.5

|

≥ 876

|

≥ 11.0

|

≥ 1990

|

≥ 25

|

287-310

|

36-39

|

180 ° C

|

||||

|

40UH

|

1240-1280

|

12.5-12.8

|

≥ 899

|

≥ 11.3

|

≥ 1990

|

≥ 25

|

302-326

|

38-41

|

180 ° C

|

||||

Application

Wide range of applications

Used in ceramics, electric power, mining, plastics, chemical, rubber pharmaceutical, food, pigments, dyes, electronics, metallurgy and other industries.

Packaging Real Shot

Can transport the magnets by Sea, by air, by express,etc

We have long-term cooperative

professional Magnet freight forwarder

, which can provide safe, fast and cost-effective transportation methods

Customer Feedback

Hot Searches