p

ay attention to temperature and humidity, it isrecommended that the indoor temperature is above 5C, the relative humidity does not exceed 60%, and a certain distance (≥300mm) from the ground and the wall. The room should be kept dry, clean, classified and stored, and clearly marked and harmful media should not be stored.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

E9Mo-15

-

Operating Current:

-

AC, DC

-

Application:

-

weld, weld

-

Samples:

-

Freely

-

Certification:

-

ISO9001

-

quality:

-

Excellent

-

inventory:

-

ample

-

wrap:

-

Spools/drums/trays

-

OEM:

-

Accept

-

MOQ:

-

5kg

-

shipments:

-

7-15days

-

Length:

-

350mm

Quick Details

-

Material:

-

Cast Iron, Low Alloy Steels

-

Welding Current:

-

70-110A

-

Operating Temperature:

-

850-900

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

E9Mo-15

-

Operating Current:

-

AC, DC

-

Application:

-

weld, weld

-

Samples:

-

Freely

-

Certification:

-

ISO9001

-

quality:

-

Excellent

-

inventory:

-

ample

-

wrap:

-

Spools/drums/trays

-

OEM:

-

Accept

-

MOQ:

-

5kg

-

shipments:

-

7-15days

-

Length:

-

350mm

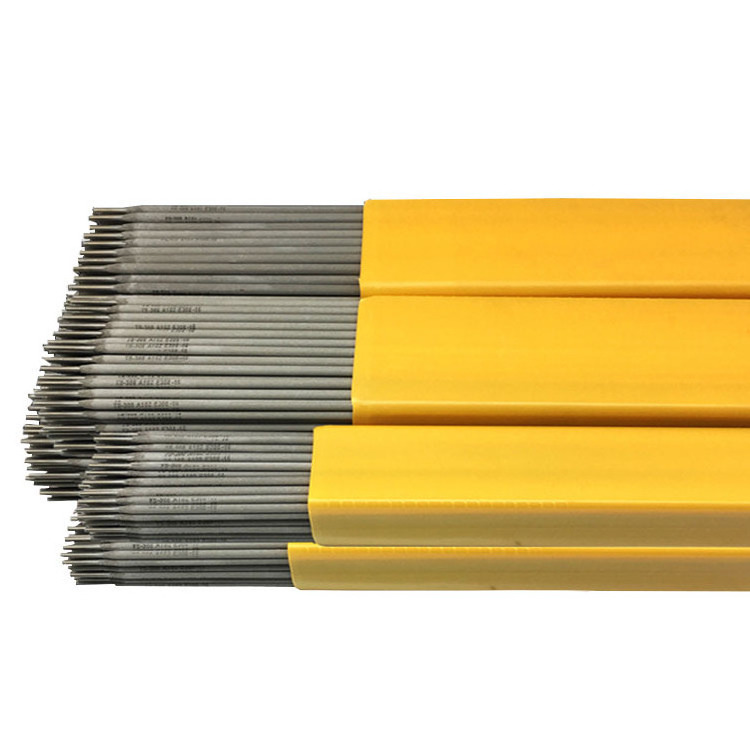

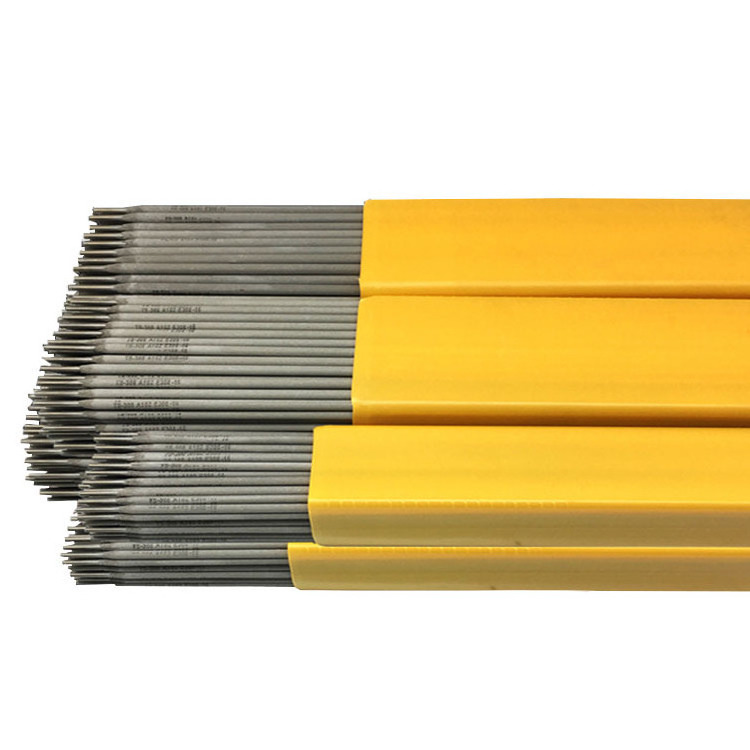

Product introduction

Description:

CHL707R is a low-alloy steel welding rod for low-sodium type chemical coating for pressurized equipment. Using DC reverse connection, it can be welded in all positions, and the deposited metal still has good impact toughness at -70℃.

|

C

|

Ni

|

Si

|

Mn

|

P

|

S

|

|

≤0.05%

|

2.0-2.75

|

≤0.5%

|

≤1.25%

|

≤0.025%

|

≤0.015%

|

|

Diameter(mm)

|

2.5

|

3.2

|

4.0

|

5.0

|

|

|

|

Welding current(A)

|

80-100

|

100-120

|

140-180

|

170-210

|

|

|

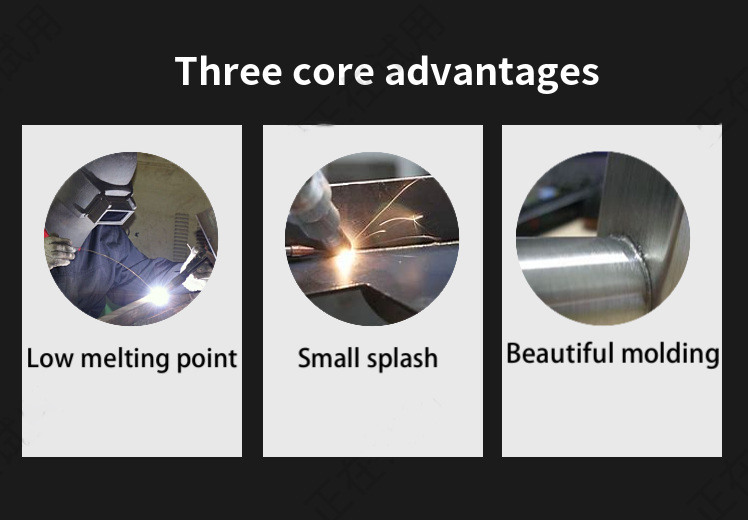

Our Advantages

Storage, storage:

Notes:

1. Before welding, the electrode must be baked at 350~380℃ for 1~2 hours, and the baked electrode should be used up in time, otherwise it must be re-baked.

1. Before welding, the electrode must be baked at 350~380℃ for 1~2 hours, and the baked electrode should be used up in time, otherwise it must be re-baked.

2. The weldment must be preheated at about 150

℃

before welding to prevent cracks .

3. When the weldment needs to be stressed, it can be tempered at 600~650C after welding.

Welding renderings

Factory introduction

Company Introduction

Aogang Lianbo Le Welding (Guangxi) Co., Ltd. is a professional de-velopment and production of electrodes and welding wire production enterprises, relying on the unique geographicallocation andunique conditions, the company has achieved countless aspiringousinessmen.The company's main products are various types otwelding electrodes; Various types of welding wires and variouswelding consumables.The company has strong scale, advancedtechnology, complete

equipment, pays attention to product quali-ty and management system innovation, and has advanced scien-tific and technological development concepts, strict enterprisemanagement system, excellent product quality, satisfactory af-ter-sales service, for Aogang United Bole Welding (Guangxi) CoLtd. has established a good corporate image, won the praise ofcustomers at home and abroad.

FAQ

Q1:What do we do?

A1:Deeply engaged in the welding consumables industry for more than ten years, with ten years of production and research and development experience, the company has strong strength, a variety of styles, to meet customer processing customization needs.

A2:Always a pre-production sample before mass production. Always final Inspection before shipment.

Q3:What canyou buy from us?

A3:Welding wire, welding rod, welding consumables accessories, farming accessories

Q4: can we visit your factory ?

A4: yes you can visit us at your free time; or we support video meeting via online for you.

Hot Searches