- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

10-70bag/min

-

Weight (KG):

-

280

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEST

-

Product name:

-

Small Dry Milk Powder Vertical Form Fill Seal Sachet Packing Machine

-

Keyword:

-

powder sachet packaging machine

-

AuiMeasuring Way:

-

Auger Filler

-

Packaging film materials:

-

Laminate film

-

Bag length:

-

30-200mm

-

Packing speed:

-

10-70bag/min

-

Film width(Bag former):

-

Max.320mm

-

Bag width:

-

Max.150mm

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, COATING, Sealing, SLITTING, counting

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic

-

Production Capacity:

-

10-70bag/min

-

Weight (KG):

-

280

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

MEST

-

Product name:

-

Small Dry Milk Powder Vertical Form Fill Seal Sachet Packing Machine

-

Keyword:

-

powder sachet packaging machine

-

AuiMeasuring Way:

-

Auger Filler

-

Packaging film materials:

-

Laminate film

-

Bag length:

-

30-200mm

-

Packing speed:

-

10-70bag/min

-

Film width(Bag former):

-

Max.320mm

-

Bag width:

-

Max.150mm

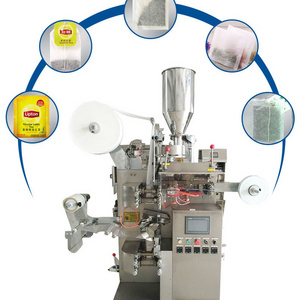

Small Automatic 2g 10g 100g Vertical Powder Coffee Tea Bag Packing Packaging Machine

Product Description

Machine Introduction:

This powder sachet filling packing machine is widely used to pack any loose,non-cohesive, granular products of the food and chemical industries, such as salt, sugar, detergent powder, coffee, rice, washing powder...

package: aesthetically perfect, without any wrinkles, the flush seams are highly resistant and all four sides can be printed on.

Main Function:

1.The

powder sachet filling packing

machine structure is compact, step motor to pull film solid Reliable, stable performance, low noise

2.Using photoelectric eye control system reliable and stable performance

3.The frequency control of motor speed, more stable operation, lower

4.Automatic measuring bagging date printing to finished products output off.

5. Use spring compression principle, pneumatic cutting, five package more stable.

2.Using photoelectric eye control system reliable and stable performance

3.The frequency control of motor speed, more stable operation, lower

4.Automatic measuring bagging date printing to finished products output off.

5. Use spring compression principle, pneumatic cutting, five package more stable.

Bag Type

Bag style for choose

1.three side sealing 2.flour side sealing 3.back sealing(pillow bag) 4.stick bag

1.three side sealing 2.flour side sealing 3.back sealing(pillow bag) 4.stick bag

Specification

|

Model

|

MEST-160

|

MEST-60

|

MEST-200

|

|

Measurment

|

Auger feeding

|

Screw feeding

|

Auger feeding

|

|

Hopper capacity

|

16L

|

10L

|

30L/50L

|

|

Film width(Bag former)

|

Max.320mm

|

40-240mm

|

Max.420mm

|

|

Bag width

|

Max.150mm

|

15-110mm

|

50-200mm

|

|

Bag length

|

30-200mm

|

30-210mm

|

30-300mm

|

|

Measurement range

|

1-5ml/5-15ml/15-50ml/50-150ml/100-500ml

|

1-5ml/5-15ml/15-50ml/50-150ml/100-500ml

|

150-1000ml

|

|

Packing speed

|

10-70bag/min

|

15-60bag/min

|

10-70bag/min

|

|

Packaging film materials

|

Laminate film

|

Laminate film

|

Laminate film

|

Machine Details

Features

1. English and Chinese screen display (other language available)

2. PLC control, function is more stable,adjustment any parameters no need stop machine.

3. Servo motor pulling film, position accurately

4. Temperature independent control system, precision get to ±1℃

5. Horizontal, vertical temperature control, suitable for various of laminated film, PE film packing material

6. Feeding, Weighing, Filling, Bag making,Sealing, Cutting, Packing, Date printing in one operation.

7.Various bag type: pillow sealing, 3 side seal,4 side seal.

8. Work circumstance quite, low noise.

9. Various bag type: pillow bag, gusset bag,stand up bag, etc.

2. PLC control, function is more stable,adjustment any parameters no need stop machine.

3. Servo motor pulling film, position accurately

4. Temperature independent control system, precision get to ±1℃

5. Horizontal, vertical temperature control, suitable for various of laminated film, PE film packing material

6. Feeding, Weighing, Filling, Bag making,Sealing, Cutting, Packing, Date printing in one operation.

7.Various bag type: pillow sealing, 3 side seal,4 side seal.

8. Work circumstance quite, low noise.

9. Various bag type: pillow bag, gusset bag,stand up bag, etc.

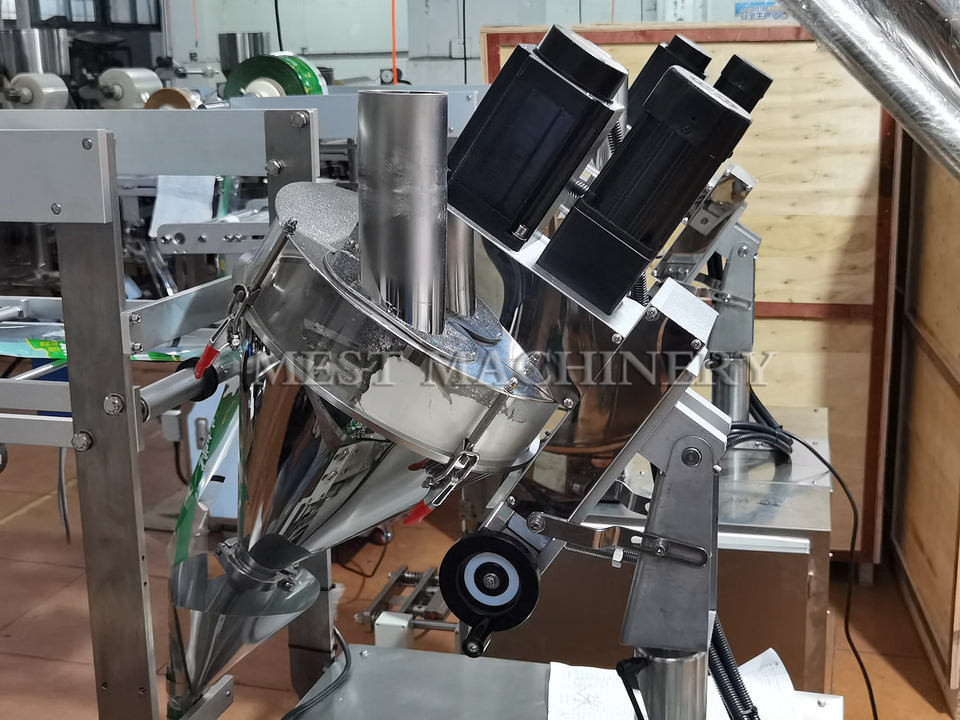

Bag former

Auger Feeding

Sealing Jaw

Ribbon Code Printer (Optional)

Details Images

Suitable For

Suitable for flour, milk powder, spices powder,Protein Powder, coffee powder with out sugar,spices, seasoning powder etc.

Packing & Delivery

Fumigation-free wooden case

Related Products

FAQ

1. Q: Are you trading company or manufacturer ?

A: We are manufacturer since 1995. You can also check this from Alibaba Certified Business Types.

2. Q: What’s the guarantee of the machine?

A: We have 2 year’s guarantee of the machine. We would like to send you new one since we have two years warranty. You also can buy from your market if more convenient. And we will take videos and pictures to teach you how to replace it. Engineers available to service machinery overseas. (You need to pay tickets, food, hotel and salary), but anyway it's up to you. But according to my experience, there's nearly no wearing parts.

3. Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 10-20 days if the goods are not in stock, it is according to quantity.

4. Q: How to install the machine after we received the machine?

A: When you received the machine, just connect it with electric and air compressor then can run it. (It will cost a little more if you need our team to your place (you need to pay tickets, food, hotel and salary), but anyway it's up to you. We’ll test the machine and make sure the machine runs well before shipment. (We’ll send the testing video for your checking)

5. Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

A: We are manufacturer since 1995. You can also check this from Alibaba Certified Business Types.

2. Q: What’s the guarantee of the machine?

A: We have 2 year’s guarantee of the machine. We would like to send you new one since we have two years warranty. You also can buy from your market if more convenient. And we will take videos and pictures to teach you how to replace it. Engineers available to service machinery overseas. (You need to pay tickets, food, hotel and salary), but anyway it's up to you. But according to my experience, there's nearly no wearing parts.

3. Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 10-20 days if the goods are not in stock, it is according to quantity.

4. Q: How to install the machine after we received the machine?

A: When you received the machine, just connect it with electric and air compressor then can run it. (It will cost a little more if you need our team to your place (you need to pay tickets, food, hotel and salary), but anyway it's up to you. We’ll test the machine and make sure the machine runs well before shipment. (We’ll send the testing video for your checking)

5. Q: What is your terms of payment ?

A: 30% T/T in advance ,balance before shippment.

Hot Searches