- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

by tap water

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Huadeyu

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

5005*1790*1830mm

-

Year:

-

2017

-

Power (kW):

-

55

-

Weight (KG):

-

10500 KG

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Type:

-

Open Mixing Mill

-

Name:

-

Two Rolls Open Rubber Mixing Mill

-

Weight:

-

12T

-

Power(W):

-

55KW

-

Certification:

-

ISO9001:2008,CE

Quick Details

-

Diameter of Roll(mm):

-

450 mm

-

Rotation Speed of Front Roll(rpm):

-

21.8 - 31.9 rpm

-

Length of Roll(mm):

-

1200 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

by tap water

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Huadeyu

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

5005*1790*1830mm

-

Year:

-

2017

-

Power (kW):

-

55

-

Weight (KG):

-

10500 KG

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Type:

-

Open Mixing Mill

-

Name:

-

Two Rolls Open Rubber Mixing Mill

-

Weight:

-

12T

-

Power(W):

-

55KW

-

Certification:

-

ISO9001:2008,CE

Application: This machine is mainly used in Rubber & Plastic Product factory for Natural Rubber Mixing(plasticating), Raw Rubber and Compound mixing, rubber warm-up mixing and pressing sheets.

Features:

1.The rolls of machine adopts titanium alloy chilled cast iron,its surface is smooth and hard,and the cavity is processed,water cooling way makes the surface temperature of the rolls be balance;

2.This machine adopts hardened reducer;

3.This machine adopts bearing,lubrication by grease or thin oil;

4.The roll gap adjustment method can be manual or electrical;

5.The electrical system adopts LS Components imported from South Korea;

6.This machine is set emergency stop button,easier operation than the traditional brake method,safety and reliable.

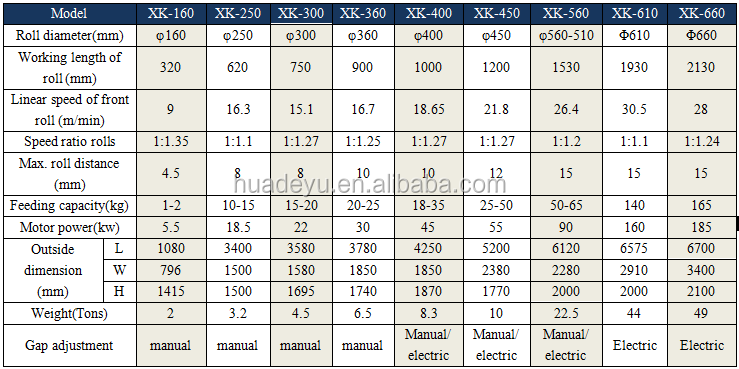

Specification:

Others Details:

1--Arrangement for Cooling and Heating

1)Circulation of steam and cooling water for heating and cooling the rolls is provided through the rolls to control the temperature by Rotating Joint.

2)Display the current temperature of each rollers onto the digital readout thermometer by the sensor.

2--Nip Guard Adjustment: Provision for opening of Nip Guard is provided for the purpose of cleaning of rolls and nip

3--Safety Switch: Hand Operated Safety Switch(Emergency Stop Button) is provided

4-- Overload Safety: Machine will be tripped off if overload to protect valuable electrical circuit

5-- Driving Motor Power: Motor and gear box with sufficient power is provided for smooth running

6-- Noise: Noise is as minimum as possible

7-- Electrical Connection: All electrical connections is that short circuit is not possible by any means

8-- Safety Guard: Safety Guards for all rotating and movable parts of the machine is provided

1. Special manufacturer and exportor who has professional producing team and technical support;

2. Exclusive and unique solution can be provided to our clients by our well-trained and professional engineer;

3--Excellent after-sales service---follow the whole producing situation,provide photos of machines loaded into containers, track the operating and using situation of client in case of any problems being occured;

4. Reasonable price,flexible delievery time and steady quality;

5. More than 10 years' experience of exporting.