- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/415V/460V

-

Dimension(L*W*H):

-

1560x840x1530mm

-

Weight:

-

500 KG

-

Power:

-

11.51kW

-

Working Temperature Range:

-

+5deg C ~ +30deg C

-

Compressor type:

-

Hermetic Scroll Type

-

Compressor Brand:

-

Copeland / Sanyo/ Danfoss

-

Refrigerant:

-

R407c/R410a/R22

-

Evaporator:

-

Shell and tube / Plate / Tank coil

-

Condenser:

-

Finned copper tube

-

Compressor quantity:

-

2 ~4unit

-

Circulation pump:

-

Installed

-

Expansion Valve:

-

Emerson/Danfoss

-

Dry filter:

-

Danfoss

-

Control System:

-

Microcomputer/PLC

Quick Details

-

Condition:

-

NEW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MGREENBELT

-

Voltage:

-

380/415V/460V

-

Dimension(L*W*H):

-

1560x840x1530mm

-

Weight:

-

500 KG

-

Power:

-

11.51kW

-

Working Temperature Range:

-

+5deg C ~ +30deg C

-

Compressor type:

-

Hermetic Scroll Type

-

Compressor Brand:

-

Copeland / Sanyo/ Danfoss

-

Refrigerant:

-

R407c/R410a/R22

-

Evaporator:

-

Shell and tube / Plate / Tank coil

-

Condenser:

-

Finned copper tube

-

Compressor quantity:

-

2 ~4unit

-

Circulation pump:

-

Installed

-

Expansion Valve:

-

Emerson/Danfoss

-

Dry filter:

-

Danfoss

-

Control System:

-

Microcomputer/PLC

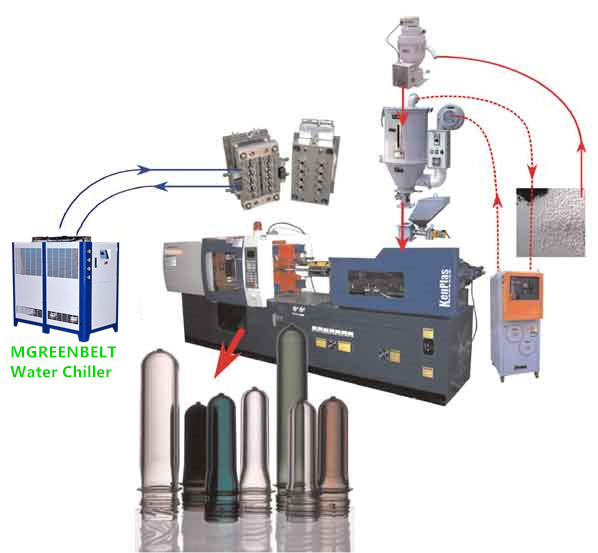

Chiller Factory 10HP 15 HP 20HP Industrial Air Cooled Water Chiller for Plastic Bottle moulding Machine

Chiller Factory 10HP 15 HP 20HP Industrial Air Cooled Water Chiller for Plastic Bottle moulding Machine

Evaporator 1

Evaporator 2

Condenser and Fans

Circulation Water Pump

Compressor

Compressor

Compressor

Plastic Injection Blow Molding Machine Cooling 30Kw 50Kw 70Kw 100Kw Air Cooled Industrial Water Chiller

|

Model

|

|

MG-10C(D)

|

MG-15C(D)

|

MG-20C(D)

|

MG-30C(T)

|

MG-40C(F)

|

||||

|

Cooling Capacity

|

Kw

|

28.5

|

41.8

|

55.3

|

83.6

|

109.6

|

||||

|

|

USRT / Ton

|

8

|

12

|

15.8

|

23

|

31

|

||||

|

|

Kcal/h

|

24510

|

35948

|

47558

|

71896

|

94256

|

||||

|

Power Supply

|

|

3PH-380V-50Hz or according to customer local need

|

|

|

|

|

||||

|

Refrigerant

|

Type

|

R22 / R407c / R404a /R507

|

|

|

|

|

||||

|

|

Control

|

Thermostatic expansion valve

|

|

|

|

|

||||

|

Compressor

|

Type

|

Hermetic scroll type

|

|

|

|

|

||||

|

|

Power (Kw)

|

4.54*2

|

6*2

|

9.05*2

|

9.05*3

|

9.05*4

|

||||

|

|

Start Type

|

Directly

|

|

|

|

|

||||

|

|

Capacity Control

|

25-50-75-100(%)

|

|

|

|

|

||||

|

Evaporator

|

Type

|

Shell and tube

|

|

|

|

|

||||

|

|

Water flow ( m3/h)

|

4.89

|

7.17

|

9.48

|

14.33

|

18.79

|

||||

|

|

Inlet / Outlet

|

DN32

|

DN40

|

DN40

|

DN65

|

DN65

|

||||

|

Condenser

|

Type

|

Air cooled high efficiency hydrophilic aluminum foll finned type

|

|

|

|

|

||||

|

|

air volume(m3/h)

|

10000

|

15000

|

20000

|

30000

|

40000

|

||||

|

Protect System

|

|

Compressor overheat protection, high/low pressure protection, phase missing/sequence protection, flow rate protection, anti-frozen

|

|

|

|

|

||||

|

Dimension

|

L(mm)

|

1560

|

1800

|

2100

|

2200

|

2500

|

||||

|

|

W(mm)

|

850

|

1000

|

1000

|

1160

|

1460

|

||||

|

|

H(mm)

|

1500

|

1600

|

1700

|

1900

|

2000

|

||||

|

N.W

|

KG

|

450

|

750

|

850

|

1150

|

1350

|

||||

Chiller Widely used in many different industries:

Mgreenbelt brand industrial chiller are the perfect solution for any application, in particular for the plastic field, such as : injection molding, extrusion(sheet & profile), blow molding, thermoforming, PET, plastic film, and other industrial field : electroplating (surface treatment), medicine, chemical, hydraulic system, leaser, shoe-making, electronic, print, etc

Professional Team: Engineering team with average 15 years of experience in industrial refrigeration, sales team with average 7 years of experience, Service team with average 10 years of experience.

-Customized solution always supplied according to requirements.

-3 steps quality control: incoming quality control, process quality control, outgoing quality control.

-12 months guarantee for all products. Within warranty, any problem caused by defects of chiller itself, service offered til the problem solved.

Q 1: If you are manufacturer or trader? Reply: We are manufacturer, all product will be factory direct price, and factory one to one directly service. Q 2: How can I choose a right water chiller model? Reply: If you have known the cooling capacity need, can find the suitable model according to our parameter data, or inform us, we choose for you. If you are not sure the cooling capacity, can inform us: (1). Your process line description, such as what's the industry, what's the production capacity, what's the power and etc; (2). What's the water flow in your system? (3). What's the inlet and outlet temperature need? (4). Or any more information you can share us, we will calculate and suggest a suitable water chiller proposal for you. If you are looking for the most suitable Water Chiller, MGREENBELT Chiller is the right choice. Call our sales manager for further guidance on the models, sizes, and configurations, and place your order at a very reasonable price. Jinan Mgreenbelt Machinery Co.,Ltd. Contact: Miss Libra Email: libra(at)mgreenbelt.com Mobile: +86-17686681007 Whatsapp /Wechat: +86-17686681007 Product qualified with CE, Saber, UL, CRN certificate.