- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

4.0 kg

-

Product name:

-

WTY-4040 RO Membrane for Industrial Water Treatment Purifier System

-

Application:

-

Water Filtration/Water Purification/Drinking Water

-

Type:

-

4040/8040

-

Certification:

-

ISO

-

Capacity:

-

250L~10000L

-

Function:

-

Producing Fresh Water

-

Usage:

-

Pure Water Process

Quick Details

-

Core Components:

-

RO Membrane

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

WTY

-

Weight (KG):

-

4.0 kg

-

Product name:

-

WTY-4040 RO Membrane for Industrial Water Treatment Purifier System

-

Application:

-

Water Filtration/Water Purification/Drinking Water

-

Type:

-

4040/8040

-

Certification:

-

ISO

-

Capacity:

-

250L~10000L

-

Function:

-

Producing Fresh Water

-

Usage:

-

Pure Water Process

Product Description

|

Mechanical Vapor Recompression Mvr Evaporator System

The chemical properties and structural materials of the reverse osmosis membrane can reduce the COD and total dissolved solids in landfill leachate wastewater, and can also be used for concentrating high-concentration substances.

|

|

Product Composition

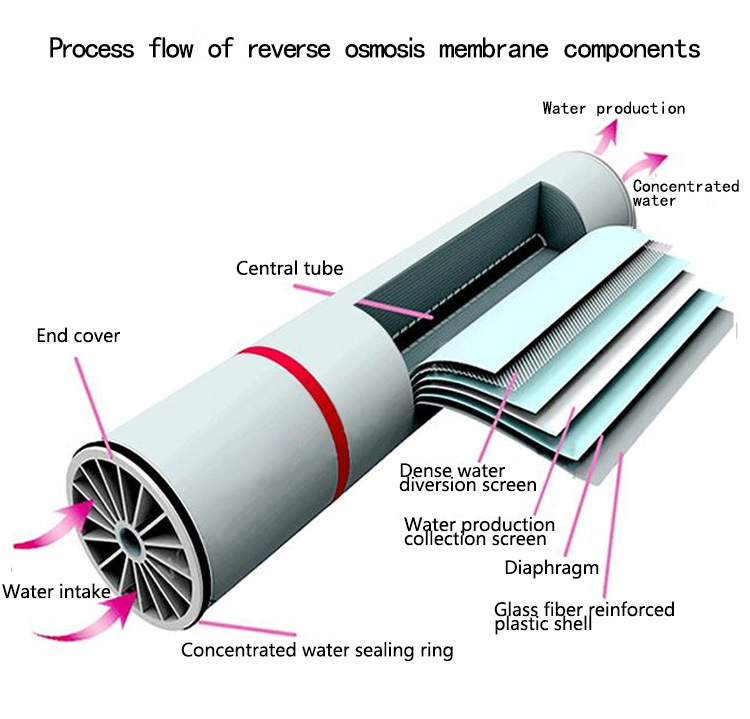

The reverse osmosis membrane is generally composed of three layers: non-woven fabric, polysulfone layer, and desalination layer. For some special performance membrane elements, a functional modification layer will be coated on the surface of the membrane.

|

Details Images

Product Parameters

|

Evaporation Process:

The RO reverse osmosis treatment unit operates on the principle that under pressure, water from the wastewater passes through the reverse osmosis membrane to become reusable water, while salts and a small amount of organic substances that cannot pass through remain in the concentrate. To alleviate the processing pressure of the reverse osmosis unit, an ultrafiltration unit has been added before the reverse osmosis treatment. Ultrafiltration can intercept particles and impurities ranging from 0.002 to 0.1 micrometers, effectively blocking colloidal substances, proteins, microorganisms, and large organic molecules.

|

|

Product Features/Advantages:

Features of reverse osmosis membrane technology:

(1) The reverse osmosis membrane separation process requires high pressure, so the process flow must be equipped with high-pressure pumps and high-pressure pipelines. The energy consumption of the reverse osmosis membrane separation process is low, without phase change, and can be carried out at room temperature, making it suitable for separating and concentrating heat-sensitive substances.

(2) It can effectively remove ions, molecules, organic colloids, bacteria, etc. from water, making it suitable for treating water with high salt content.

(3) It has a high desalination rate and water recovery rate.

(4) The membrane separation device is simple and easy to automate.

(5) During the separation process, membrane fouling may occur, so regular cleaning of the membrane is required.

(6) To prevent membrane fouling, the raw water needs to undergo certain pretreatments, and only after meeting the standards can it enter the reverse osmosis membrane separation device.

|

|

Application Scope:

Application in industrial water supplyThe quality of tap water and groundwater mostly fails to meet the requirements of the chemical, electronics, and textile industries. It needs to be purified before use, and ultrafiltration membrane technology is one of the important technologies for purifying industrial water.

Application in process water treatment (separation, concentration, classification, and purification)

In various industrial production processes, there is often a need to separate, concentrate, classify, and purify certain aqueous solutions. Traditional methods include precipitation, filtration, heating, freezing, distillation, extraction, and crystallization processes.

Application in the food industry

Membrane technology has been adopted in the clarification and concentration of soy sauce and vinegar, fruit juice clarification, dairy product production, and the sugar-making industry.

Applications in various industrial productions

Membrane technology can be used in molecular-level concentration and separation processes. Ultrafiltration membranes are used for the online purification of automotive electrophoretic paints to remove impurities and continuously ensure coating quality; the fuel industry uses ultrafiltration membrane technology to separate and concentrate intermediates. Application in environmental protection and water resource utilizationMembrane technology is widely used in wastewater treatment, pollution prevention, and comprehensive utilization of water resources. In many cases, not only is the wastewater treated, but useful substances and energy can also be recovered.

(1) Treatment of various oily wastewaters and waste oils

① Treatment of oil recovery injection water: Membrane methods can remove emulsified dissolved oil from water, improving the quality of injection water.

② Treatment of oily wastewater: Many industrial productions and transportation businesses generate a large amount of oily wastewater, and membrane filtration technology is an effective method for standard discharge.

③ Purification of waste lubricating oil: Using conventional technology combined with membrane separation, very pure lubricating oil can be obtained, suitable for treating waste engine oil from automobiles, etc.

④ Purification and recovery of machine cutting oil: Membrane methods can remove bacteria and impurities from waste cutting oil for reuse after treatment.

⑤ Purification treatment technology for waste cooking oil: Cooking oil produces carcinogens under continuous high temperatures, which can be removed using membrane methods.

⑥ Purification of edible rapeseed oil: Rapeseed oil contains 15% to 48% of high carbon content erucic acid. Membrane methods can remove it to meet standards (erucic acid <5%).

(2) Treatment and reuse of wastewater

① Treatment and reuse of printing developing wastewater: Membrane technology can achieve standard discharge and recovery.

② Electroplating wastewater can be treated with membrane technology for water reuse and recycling of pollutants.

③ Dyeing and printing wastewater can be treated with membrane separation to remove colored dyes, and the resulting water can be reused. Indigo dye from denim printing wastewater can be recovered.

④ Papermaking wastewater can be treated with membranes to separate out lignin, colorants, etc., and the purified water can be discharged or reused.

Application in water desalination

① Seawater desalination technology: Membrane distillation technology combined with marine engine heat exchangers utilizes waste heat to produce fresh water, suitable for small and medium-sized fishing vessels for long-distance fishing.

② Brackish water desalination technology: Natural brackish water is desalinated to the standard of applicable water quality using membranes.

|

Hot Searches