Support customization of various types of patterns

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

6200mm-7500mm*2600mm-3200mm*1750mm

-

Weight:

-

1000 kg

-

Finished Products:

-

tissue paper making machine

-

Name:

-

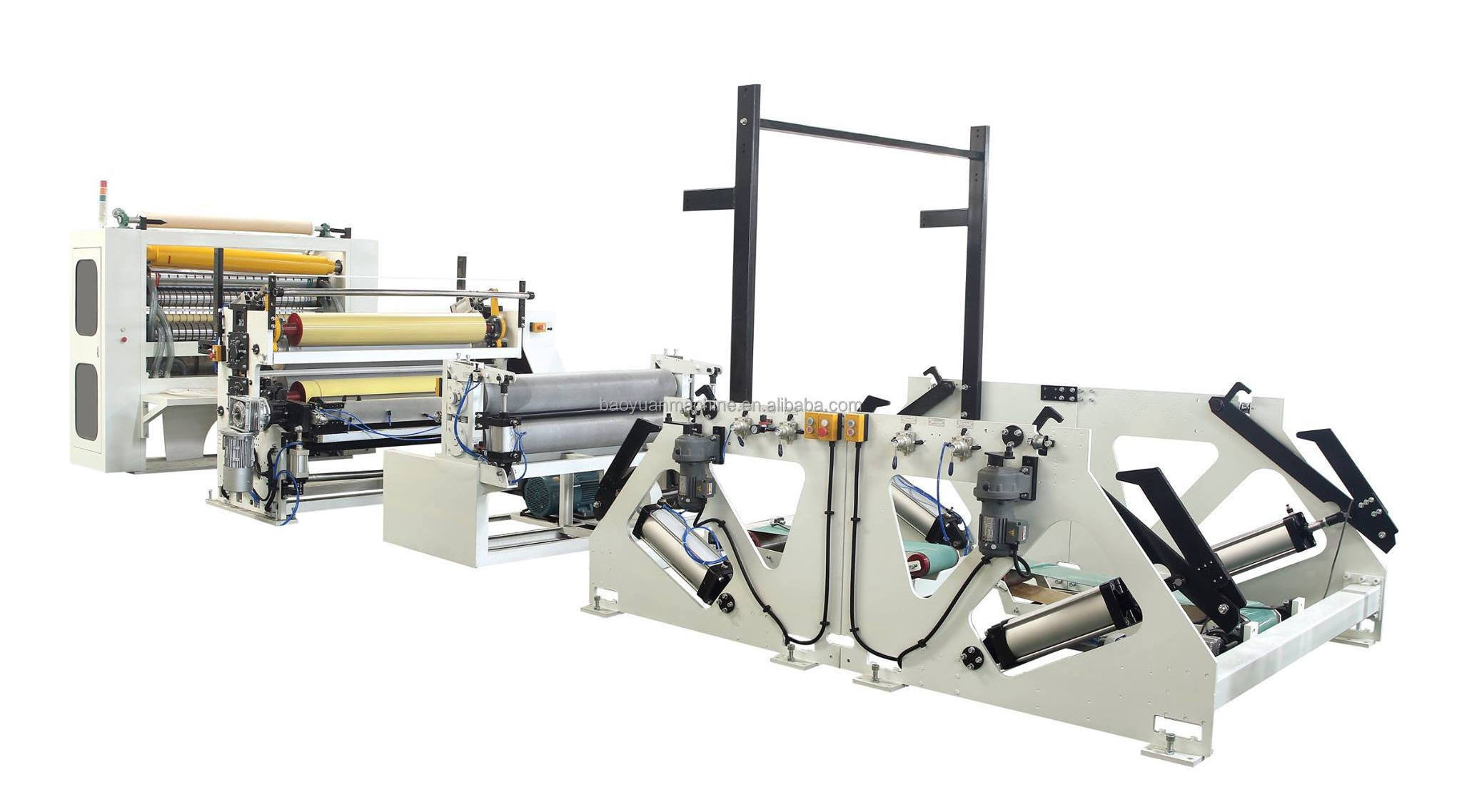

Toilet Paper Rewinding Machine

-

Product name:

-

Tissue Paper Rewinding Machine

-

After Warranty Service:

-

Online Technical Support

-

Raw material:

-

Paper White Shaving

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

Household Tissue Paper Production

-

Speed:

-

150-280M/min

-

Function:

-

Produce Tissue Paper

-

Keyword:

-

toilet paper making machinery

Quick Details

-

Production Capacity:

-

150-280M/min

-

Place of Origin:

-

China

-

Voltage:

-

380V, 50HZ

-

Power:

-

6.5KW

-

Dimension(L*W*H):

-

6200mm-7500mm*2600mm-3200mm*1750mm

-

Weight:

-

1000 kg

-

Finished Products:

-

tissue paper making machine

-

Name:

-

Toilet Paper Rewinding Machine

-

Product name:

-

Tissue Paper Rewinding Machine

-

After Warranty Service:

-

Online Technical Support

-

Raw material:

-

Paper White Shaving

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Application:

-

Household Tissue Paper Production

-

Speed:

-

150-280M/min

-

Function:

-

Produce Tissue Paper

-

Keyword:

-

toilet paper making machinery

Product Overview

Facial tissue production line combined embossing, folding, counting, match with high-speed paper cutting machine, conveying,automatic bag, automatic seal bags. It much save manpower. This machine adopt PLC computer programming technology, frequency control, servo feeding control, match with touch type screen man-machine interface operating system. The whole machine adopts synchronous belt drive. Folding machine can match with automatic tension control system, to suitable various kind of raw material, greatly improve quality and efficiency. This production enjoy with easy operation flow, high production efficiency, perfect product , moreover, it can match with full-automatic heat shrink packaging machine. Full-automatic high-speed soft bag packing machine.

FEATURES AT A GLANCE

Functions and Features:

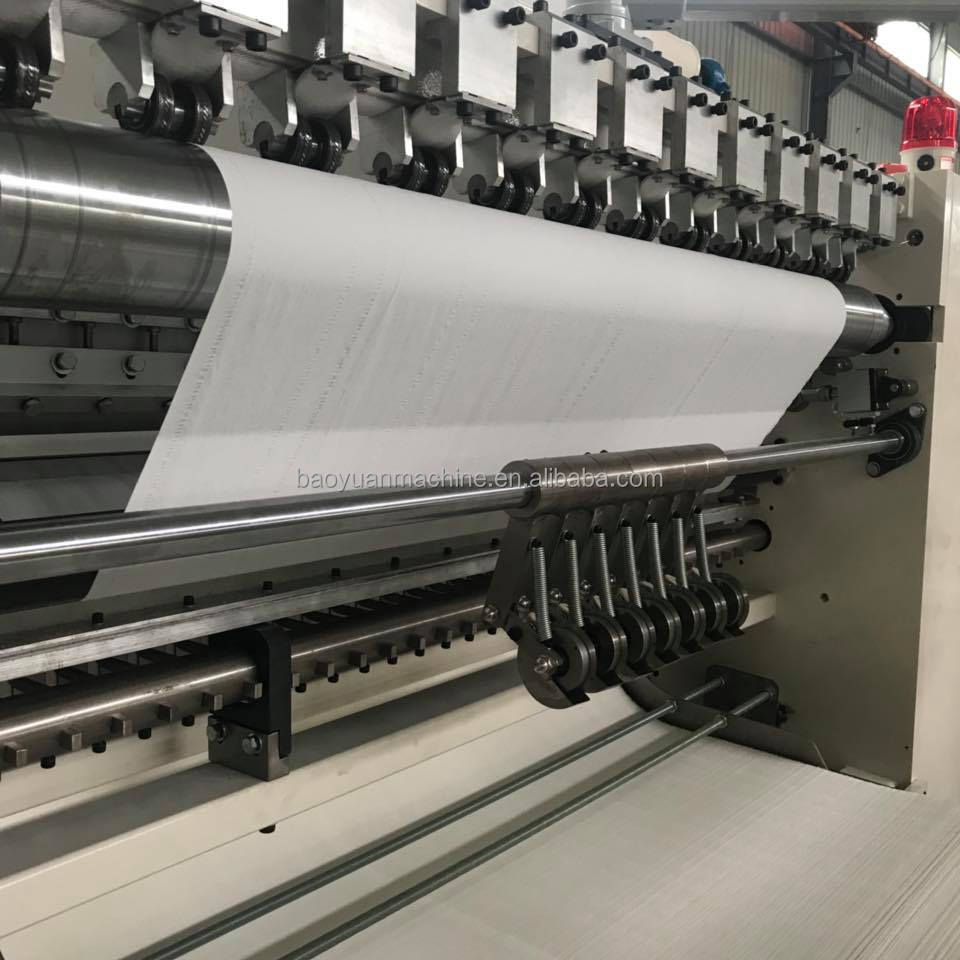

facial tissue making machine working flow :The jumbo rolls which have been slit into the desired width are cut by the slitting cylinders,and then interfolded into interoverlapped rectangular facial tissue sheets.This machine adopts independent servo motor drive ,and automatic paper tension control. It features of high speed ,nice folding and easy operation .

1. Can order steel to rubber embossing rolls,pneumatically separated.

2.Wallboard rack and Machine running stability and extremely good and fast.

3.Pneumatic jumbo roll loading,pneumatic paper driving ,stepless speed additionustment ,and web tension control.

4.Equipped with roots type vacuum pump for stable running of the machine

5.Make various products width as requirement .

6.Equipped with edge embossing unit to keep the two plies together.

7.The machine will stop when the paper broken.It avoid waste caused by no paper or paper broken.

8.The web can be threaded on the machine by the two jog buttons,It's more safety and easier to thread the web.

PRODUCT SPECIFICATIONS

|

Products unfolded size

|

180/190/200/210×(120-210)mm (width is adjustable)

|

|

Products folded size

|

90/95/100/105*(130-210)mm (width is adjustable)

|

|

Jumbo roll specification (mm)

|

width 420mm

13~17g/m2×2 ply Jumbo roll diameter ≤1100mm |

|

Jumbo roll core inner diameter

|

76.2mm (Other sizes can be designated)

|

|

machine speed

|

60-100 m/min*lines

|

|

Embossment unit

|

Steel to rubber roller, steel to steel embossment, steel to paper roller. (standard is steel to paper roller, can be chosen by

customer) |

|

Edge embossment

|

Steel to steel, independent pneumatic adjustment

|

|

Slitting system

|

Pneumatic mode point-cutting

|

|

Vacuum system

|

15KW

|

|

Pneumatic system

|

3Pa air-compressor, minimum pressure 5kg/cm2 Pa (customer should prepare)

|

|

Machine power

|

9kw/11kw/15kw/22kw, (380V, 50Hz)

|

|

Driving system

|

Timing belt driving

|

Successful Project

Project in

Pakistan

Project in

Bangladesh

Project in South Africa

SIMILAR PRODUCTS

FAQ

Pre-Sales Service:

1. Offering comprehensive technical and business consultation services and feasible report according to customers` realsituation.2. Proposing the most suitable scheme and equipment for our clients;

3. Designing and fabricating targeted products according to the special requirements of clients;

4. Detailed design of workshop and whole factory are available.

On-sales:

Provide installation guidance in locale and online.

After-sales Service:

1. Fast & Safe Delivery;

2. All of our products are tested before the delivery.

3. Dispatching engineers to install and test machine;

4. Make a training to clients’engineers and workers is supported.

5. We supply spare part with best price.

6.Our engineer team is always at your disposition to resolve your problems about installation,

operation and maintenance.

1. Offering comprehensive technical and business consultation services and feasible report according to customers` realsituation.2. Proposing the most suitable scheme and equipment for our clients;

3. Designing and fabricating targeted products according to the special requirements of clients;

4. Detailed design of workshop and whole factory are available.

On-sales:

Provide installation guidance in locale and online.

After-sales Service:

1. Fast & Safe Delivery;

2. All of our products are tested before the delivery.

3. Dispatching engineers to install and test machine;

4. Make a training to clients’engineers and workers is supported.

5. We supply spare part with best price.

6.Our engineer team is always at your disposition to resolve your problems about installation,

operation and maintenance.

About us:

Gongyi baoyuan Machinery Co., Ltd With more than 20 years of manufacturing experience. Adhering to the "excellence" concept, JingYi Machinery is committed to providing customers with more professional equipment and better service.

The main products are toilet paper machine, facial tissue machine, napkin paper machine, handkerchief paper machine and other machinery, including toilet paper rewinding and perforating machine, full servo log saw machine, box drawing facial tissue machine, napkin paper machine, handkerchief paper machine and the related packing machine.

In recent years, we have developed new technolocy for toilet paper rewinding machine and facial tissue folding machine, produced fully automatic wallboard structure high speed color glue lamination toilet paper rewinding machine and automatic stacking facial tissue folding machine with color glue lamination.

Our machine have been exported to more than 60 countries, such as United Kindom, Poland, France, Ukraine, Russia and other Europe countries; USA, Canada, Bolivia, Chile, Brazil, Argentina and other South American countries; Nigeria, Ethiopia, South Africa and other African countries, as well as the Middle East, Southeast Asia and other countries. Our machines and services have been unanimously approved by customers.

Hot Searches