- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

zhongyou

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

3 T

-

Model Number:

-

YM

-

Motor Power (kw):

-

7.5 kw

-

Warranty:

-

1 Year, 1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

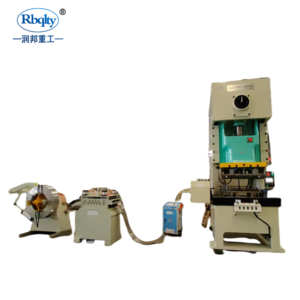

automatic mesin stamping bearing press machine

-

Application:

-

bearing press machine

-

Material:

-

Cast Iron hydraulic press machine

-

Function:

-

mesin stamping hydraulic press machine

-

Port:

-

Qingdao

-

stroke:

-

can be customized automatic press machine

-

Work Table Size:

-

customized

-

Usage:

-

Punching Effectively press machine

-

Certification:

-

CE ISO

Quick Details

-

Machine Type:

-

H Frame Hydraulic Press

-

Return Force (kN):

-

50 kN

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zhongyou

-

Voltage:

-

380V/220V Optional

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

3 T

-

Model Number:

-

YM

-

Motor Power (kw):

-

7.5 kw

-

Warranty:

-

1 Year, 1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

automatic mesin stamping bearing press machine

-

Application:

-

bearing press machine

-

Material:

-

Cast Iron hydraulic press machine

-

Function:

-

mesin stamping hydraulic press machine

-

Port:

-

Qingdao

-

stroke:

-

can be customized automatic press machine

-

Work Table Size:

-

customized

-

Usage:

-

Punching Effectively press machine

-

Certification:

-

CE ISO

automatic mesin stamping bearing press machine

This automatic mesin stamping bearing press machine is suitable for all major, medium and small enterprises, factories, industrial and mining and auto repair shop, heavy machinery, flange, belt plate, shaft bushing, bearing disassembly operations, calibration correction, bending, Punching, blanking, stretching, folding to replace the old spiral hand press for compression operations, the real realization of a multi-purpose machine.

1, the host part: the stamping press machine for the gantry hydraulic press, the cylinder installed in the bottom of the top of the hole, the first card in the bottom of the cylinder plunger, with the role of reciprocating reciprocating motion with the plunger.

2, the hydraulic system: the hydraulic system installed on the right side of the host, the entire hydraulic control system by the motor to drive high-pressure pump input pressure oil, through the relief valve, solenoid valve, pressure gauge, pipe and other input cylinders, movement. The press control device.

The pressure gauge can show system pressure. The use of advanced steel plate welding technology, up and down the activities of large space, easy to suppress the workpiece, can be preset working pressure, can be equipped with electronic digital tonnage display (optional), hydraulic system cooling device (optional). The stamping press machine table can move up and down, greatly expanding the height of the machine opening and closing, it is more convenient to use.

.

safety protection

1, set the emergency stop button, press the emergency stop button, press immediately stop.

2, the trip in the upper and lower limits are located at the limit switch.

3, in the piston cylinder lower chamber set hydraulic support insurance valve circuit to ensure safety. At the same time set the hydraulic interlock circuit to ensure that the support does not open the fuse, the master cylinder can not output pressure on the cavity.

Maintenance:

1. the

small bearing press machine

must be strictly filtered oil can be injected into the tank, the oil level can not be lower than the oil standard instructions.

2.the fuel tank every six months to clean and replace the new oil once, the first time to replace the oil should not be more than three months, the oil can be re-filtered and then once.

3.Check the pressure gauge once every six months.

4.When the

stamping press machine

is deactivated for a long period of time, clean the surface and clean the rust.

The series of automatic mesin stamping bearing press machine rigidity, high precision, anti-partial load capacity. This type of stamping bearing press machine for pressure, correction, stretching, bending, forming, blanking, flanging and other stamping process, but also for powder metallurgy, auto parts, household appliances, kitchen utensils and other compression molding process.

The company is a professional hydraulic press, press, four-column hydraulic machine, single-column hydraulic press, automatic mesin stamping bearing press machine research and development, design and manufacturing and marketing services of private enterprises.The company relies on a strong economic strength, advanced sophisticated professional production equipment, strong technical force, and a standardized enterprise management system model to operate.

The company's products are widely used in automotive, metallurgical, textile machinery, plastics, rubber, ceramic products, powder and refractories and other industries. The company adhere to the integrity-based, the credibility of the first, the user first for the purpose. With reliable quality and sincere service to build the majority of new and old customers of the integrity of cooperation.

- stamping press machine Packaging Details

- Exporting standard wooden case package or as per clients' request

- bearing press machine Delivery Time

- Shipped in 30 days after payment

FAQ:

1.How to control quality?

all equipment include small automatic mesin stamping press machine shall be inspected by the inspection personnel of the manufacturer before they go out.

2.Are we a manufacturer?

Yes, we are engaged in the production of bearing press machine manufacturers.

3.Where is our company?

No.219,Xingye North Road,Economic Development Area,Tengzhou City,Shandong Province.

FAQ:

1.How to control quality?

all equipment include bearing press machine shall be inspected by the inspection personnel of the manufacturer before they go out.

2.Are we a manufacturer?

Yes, we are engaged in the production of mesin stamping press machinery manufacturers.

3.Where is our company?

No.219,Xingye North Road,Economic Development Area,Tengzhou City,Shandong Province.

friendly reminder:

1: all equipment including

automatic bearing press machine

shall be inspected by the inspection personnel of the manufacturer before they go out, The test will be sent out after passing the test.

2: The equipment for example mesin stamping press machine provides a year of free maintenance, lifelong maintenance.

The price of the product is fluctuating, Please consult us for details.