The casting on Clamping increases the grasping force, meanwhile does not scratch the material

- Product Details

- {{item.text}}

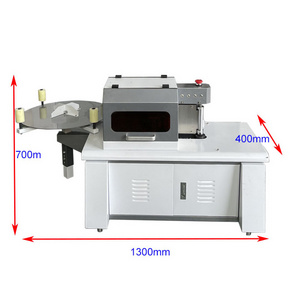

Quick Details

-

Weight (KG):

-

900

-

Product name:

-

ET75 channel letter bending machine

-

Slotting method:

-

Plane cutter

-

Bending method:

-

Beating

-

Working space:

-

6350*1860*2350mm

-

Suitable materials:

-

Stainless steel,galvanized sheet and aluminum plate

-

Slotting trip:

-

400-750mm

-

Material thickness:

-

0.4-1.5mm

-

Control system:

-

4 Servo Axis Control System

-

File Format:

-

Dxf.PIt.Ai

-

Machine weight:

-

3000Kg

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

EJON

-

Marketing Type:

-

New Product 2024

-

Weight (KG):

-

900

-

Product name:

-

ET75 channel letter bending machine

-

Slotting method:

-

Plane cutter

-

Bending method:

-

Beating

-

Working space:

-

6350*1860*2350mm

-

Suitable materials:

-

Stainless steel,galvanized sheet and aluminum plate

-

Slotting trip:

-

400-750mm

-

Material thickness:

-

0.4-1.5mm

-

Control system:

-

4 Servo Axis Control System

-

File Format:

-

Dxf.PIt.Ai

-

Machine weight:

-

3000Kg

|

SPECIFICATIONS

|

|

|

|

|||

|

Feeding system

|

Double ball-screw alternate feeding system

|

|

|

|||

|

Slotting System

|

Milling plane cutter

|

|

|

|||

|

Bending System

|

Double blade alternate bending system

|

|

|

|||

|

Suitable Material

|

Stainless steel, Galvanized steel, Aluminum plate

|

|

|

|||

|

Material Height

|

Stainless steel、Galvanized steel、Aluminum plate:20~750mm

|

|

|

|||

|

Material Thickness

|

0.4~1.2m

|

|

|

|||

|

Accuracy

|

±0.1mm

|

|

|

|||

|

Min. Bending Angle

|

R15

|

|

|

|||

|

File Format

|

Dxf.Plt.

|

|

|

|||

|

Power

|

AC220V、50Hz、4.0Kw

|

|

|

|||

|

Control System

|

4 axis control system (4 axis servo control)

|

|

|

|||

Main Features

1) The bending adopts high power servo motor, high torque, high forming degree, and high-strength ball screw to meet the high load working condition.

2) The bends with wear-resistant surface, adopts high-strength alloy material, high-temperature quenching process, achieves high hardness, high strength, high wear resistance.

3) The slotting mechanism adds a new air blowing and cooling function to extend the service life of the cutter while ensuring smooth slotting.

Machine Parts

Main Features

The double ball screw of feeding design ensure the feeding speed and precision as well as stability

Machine Parts

Double-cutter slotting, using plane cutter for Galvanized sheet, Stainless steel and Aluminum plate.

Main Features

The encoder module is the key component of the the relation equipment precision , and the precision casting is used to ensure the performance of the high precision encoder.

Computer

To use the device, you need to install the control card in your computer and then connect to the bending machine and install the software.Computer configuration :

XP system or window7 32-bit system, and requires a PCI card slot to install the control card.

Pump

The use of equipment should be equipped with

air compressor

, we suggest that the selection of

more than 4kw, the gas flow is 0.6m³/Min.

File Format

The software of bending machine is self-developed. Import file format supports

.Dxf.Plt .AI

We recommend using

Coredraw or adobe illustrator

to complete the file after the export file to.Dxf.Plt.Ai format. Then open the operating software, select the document.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact us

Ivy Liu

Tel: 0086-17526997508

Whatsapp/Wechat: +0086-17526997508