Application:

Specially designed for tire bead and other rubber products needing reinforcing.

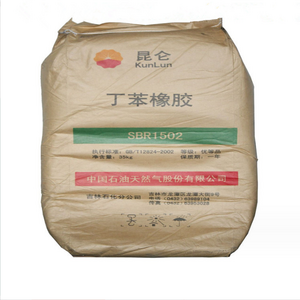

Packing and storage:

Resin is packed in 25kg or 40kg composite kraft paper bag with three layers or PE bag (other packing requirements are subject to customer requirements). To prevent moisture absorption, resin must be stored in a well ventilated, cool and dry place and away from direct sunlight, or rain during transportation. Handle with care and avoid sharp objects to prevent breaking bags. Typical shelf life is 1 year.