- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KSBOND

-

Model Number:

-

Epoxy Resin EP225

-

Type:

-

epoxy resin for glassfiber, high temperature resistant epoxy resin

-

Product name:

-

transparent potting glue, high temperature resistant epoxy resin

-

Item name:

-

epoxy adhesive

-

Certificate:

-

ISO 9001-2008; ROHS; MSDS

-

Color:

-

colorless buff transparent liquid

-

Mixing Ratio:

-

water based, Waterbased

-

Shelf Life:

-

18 Month

-

Advantage:

-

water resistance and chemical corrosion resistance

-

Keywords:

-

transparentr epoxy adhesive

Quick Details

-

CAS No.:

-

Mixed

-

Other Names:

-

Poly Vinyl Acetate

-

MF:

-

Mixture

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

KSBOND

-

Model Number:

-

Epoxy Resin EP225

-

Type:

-

epoxy resin for glassfiber, high temperature resistant epoxy resin

-

Product name:

-

transparent potting glue, high temperature resistant epoxy resin

-

Item name:

-

epoxy adhesive

-

Certificate:

-

ISO 9001-2008; ROHS; MSDS

-

Color:

-

colorless buff transparent liquid

-

Mixing Ratio:

-

water based, Waterbased

-

Shelf Life:

-

18 Month

-

Advantage:

-

water resistance and chemical corrosion resistance

-

Keywords:

-

transparentr epoxy adhesive

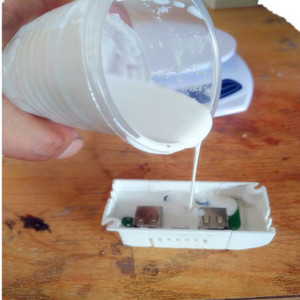

Electronic transparent potting glue, high temperature resistant epoxy resin

Product Description

EP225 can be applied as the bottom coating on the concrete, terrazzo, metal and so on. It has the characters of high penetrability, good adhesion to the substrate, great water resistance after hardening, great corrosion resistance, which has much irreplaceable superiority to many otherproducts.

Properties;

|

Item |

A(resin ) |

B(hardener ) |

|

Appearance |

L ight yellow transparent liquid |

Brown transparent liquid |

|

Mix ratio (weight) |

A:B=4:1 |

|

|

Work time (25℃) |

30min/160g |

|

|

surface drying time(25 ℃ ) |

4-5hr |

|

|

Reference dosage |

0.15kg/m2 ( Smooth surface ) 0.25kg/m2 (rough surface ) |

|

|

cement mortar adhesion |

88 kg/cm2 (JISR5201) |

|

Directions for use:

Firstly, remove the bad hardening layer , grease, rust and dust on the surface.

S econdly, mix A and B with the ratio, evenly stirring, then pull on the construction ground in the working time.

Caution:

1. I n order to get great adhesion , the pretreatment of the substrate must meet the requirements.

2. Pay attention to the accuracy ratio, and it should be evenly stir red after mixing A and B agent

3. when in construction, let the glue infiltrate into The pore of the surface, but should keep the Thickness less then 0.5mm, the thinner the better , to ensure the solvent can be fully evaporate and cure completely.

4. T he amount of the products should be mixed according the working time, different temperature can cause the different working and the amount.

F irst aid

1. If skin contacted in operation, rub with sand or flour quickly to remove the glue firstly, and then wash with soap.

2. Do not use under 5 ℃ .

Package and storage:

20kg/set,keep in cold and dry place, temperature between 5-35℃, 2 years