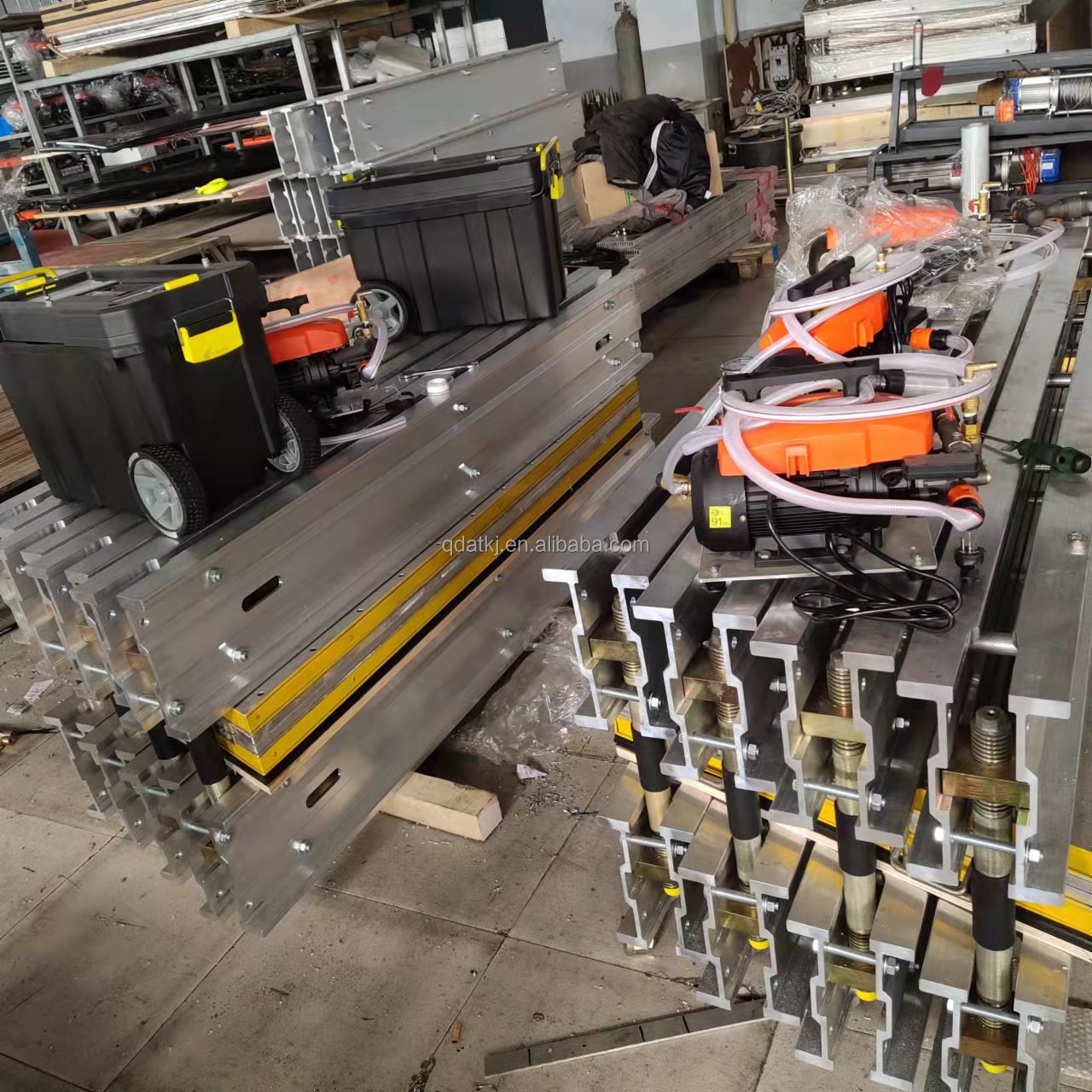

Air bag pressure system for conveyor belt vulcanizer

Special designed cooling system within platens

Innovative "Silicone Element" fast heating system

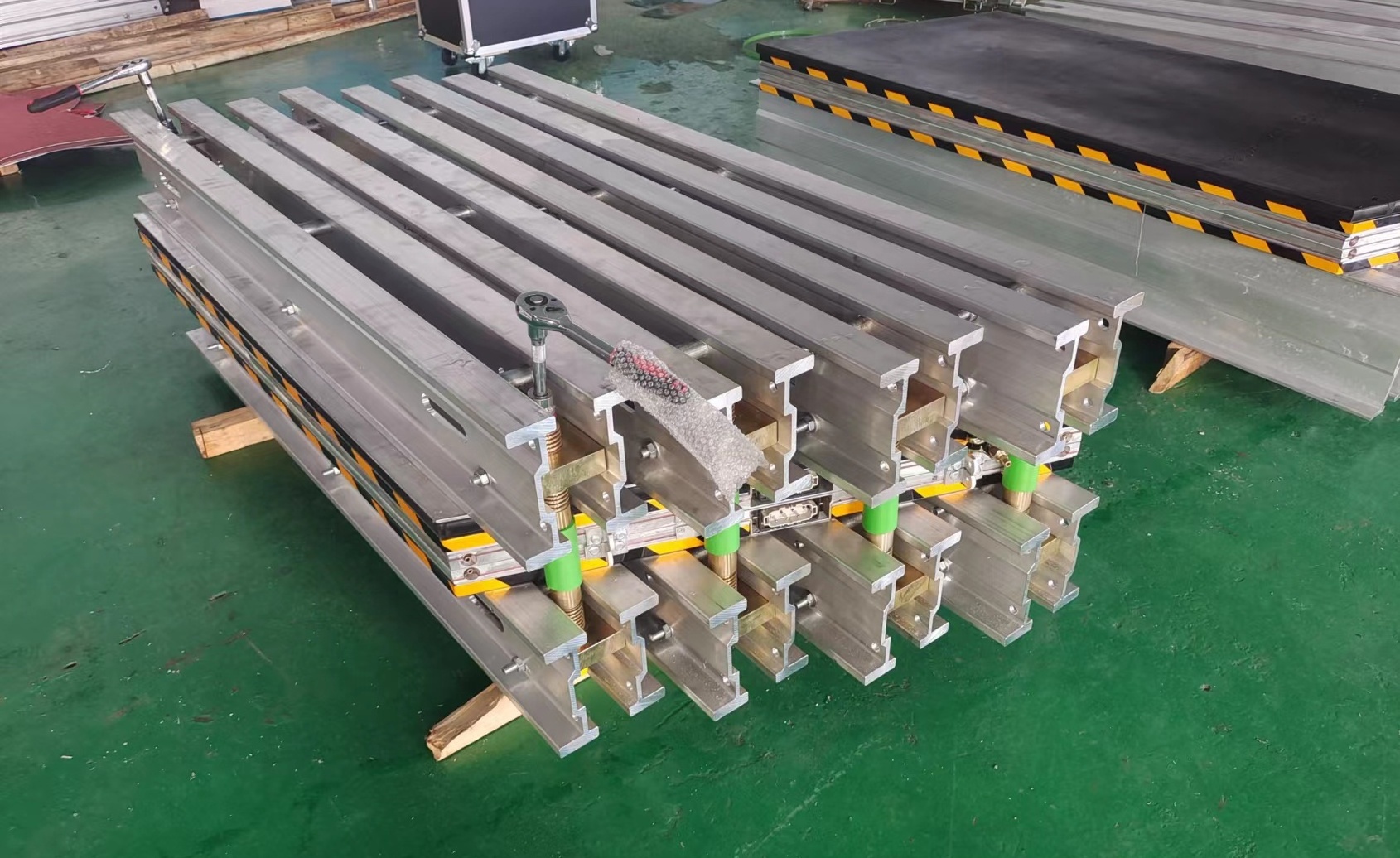

Light but sturdy structure of extruded aluminum alloy traverse beam

Quick connector for high pressure hose

Classic ZLJ control box for reliable control

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

1520*1000*630 MM

-

Year:

-

2023

-

Power (kW):

-

13.5 kW

-

Weight (KG):

-

570 KG

-

Products Name:

-

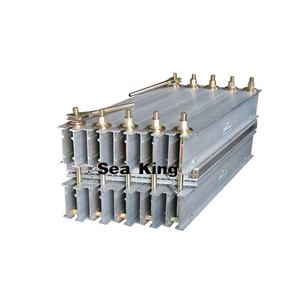

Conveyor Belt Splicing Machine

-

Raw Material:

-

Aluminum Alloy

-

Belt Width:

-

≤800 mm

-

Splice Length:

-

≤1000 mm

-

Model:

-

ZLJ-800*1000

-

Power:

-

13.5 kw

-

Dimensions:

-

1520*1000*630 mm

-

Weight:

-

570 kgs

-

Vulcanizing Temperature:

-

145 Degree

-

Heating Time:

-

≤25 min

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Antai

-

Core Components:

-

Silicone Blanket Heating Element, Hot Plate with Cooling System, Rubber Pressure Bag, Auto Electric Control Box

-

Voltage:

-

Customer Request

-

Dimension(L*W*H):

-

1520*1000*630 MM

-

Year:

-

2023

-

Power (kW):

-

13.5 kW

-

Weight (KG):

-

570 KG

-

Products Name:

-

Conveyor Belt Splicing Machine

-

Raw Material:

-

Aluminum Alloy

-

Belt Width:

-

≤800 mm

-

Splice Length:

-

≤1000 mm

-

Model:

-

ZLJ-800*1000

-

Power:

-

13.5 kw

-

Dimensions:

-

1520*1000*630 mm

-

Weight:

-

570 kgs

-

Vulcanizing Temperature:

-

145 Degree

-

Heating Time:

-

≤25 min

ZLJ CUSTOM SECTIONAL VULCANIZING PRESSES

Engineered by ANTAI Group is the world's preferred heavyweight sectional vulcanizing press. Offering great size versatility with complete coverage of all splice lengths, either fabric ply, PVC/PVG, PU or steel cord. ZLJ PRESS is extremely portable and its expendability makes it the number one industry splice choice. As with all pressing equipment from ANTAI, each unit press is distinguished by the core competencies of ANTAI technology.

Features

• Signature ANTAI "Pressure Bag" uniform pressure system.

• Custom "Extruded Plank" cooling system within platens.

• Innovative "Silicone Element" fast heating system.

• Automatic mute pressure pumps for operating pressures up to 23kg/cm2 (2.3MPa).

• ZLJ platens are built to order with all dimensions offered to accommodate various belt widths.

• DELIXI electrical apparatus element assembled into insulating and waterproof control panel.

• All electrical systems are CE, CSA and UL approved.

Specifications

1. Voltage: 220V 380V 415V 525V 660V 1140V 50HZ/60HZ(Customize available according to your requirement)

2. Quick water cooling device: 15 minutes {From 145 ℃(293℉)down to 80 ℃(176℉ )or even lower}

3.Cooling source: Water/Air

4.Heating source: Electricity

5. Heating time: from room temperature to vulcanization temperature need less than 20 minutes

6. Heating plate surface temperature difference: ± 1 ℃(33.8℉)

7. The temperature adjustment range: 0 ~ 200 ℃/0~392℉ (custom)

8. Vulcanization pressure: Max 2.5MPa.

9. Curing temperature: 0 ~ 99min (according to the thickness of the belt to adjust)

Usually 10mm~25mins, 20mm~35mins

10. Automatic mute pressure pump

11. Automatic control panel: insulating and waterproof, security alarm, Auto power-off when reach the vulcanization temperature.Upgrading explosion proof control box option available.

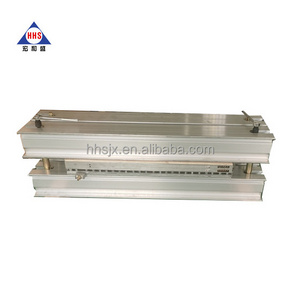

•HEATING PLATEN

Custom extruded plank, silicone heating elements (up to 180°C/356°F), and durable composite insulating packaging are used to construct a flexible platen that contours to belt irregularities.

The heating elements is made up with a whole piece of silicone plate without any splicing point, which ensure the full uniform heating as well as the fast rising of temperature. It takes 15~25mins rise up to vulcanizing temperature (about 145°C).

The flush "quick connect" make smooth profile. Recessed power connections are sealed for moisture resistance.

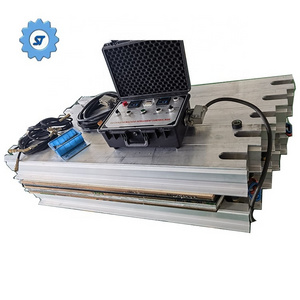

•PRESSURE SYSTEM

Signature ANTAI "Pressure Bag" uniform pressure system was developed by ANTAI Group since 2005, which is an innovation of outdated heavy pressure bag. It is lighter up to 4 times than the outdated pressure bag.

With the one whole piece of vulcanized rubber plate, it is sealed, isolated, rust-proof and without any splicing area, which ensures the safety during the operation.

The pressure bag can reach full expansion in one time and ensure the uniform pressure up to 3.0MPa, fully meet the requirements of belts' vulcanization.

The frame thickness of the pressure bag is only 2cm rather than 5cm for the outdated one, which increases the area of pressure, improve the quality of vulcanized belts.

• PRESSURE PUMP

Automatic mute pressure pump own the features as smaller size, lighter weight, high impact-resistance and twice times faster speed of water injection. Compared with the manual pump, the operating pressure can be 23kg/cm2 (2.3MPa).

The pump includes gauges for fluid level and pressure. Extra reservoirs easily added for larger presses. It can be upgraded to explosion proof as your requirement.

• COOLING SYSTEM (Option Available)

Custom "Extruded Plank" cooling system within platens is made by several cuprum pipelines, it only takes about 20mins to drop the temperature down to 60°C.

•AUTOMATIC CONTROL BOX

The New-Style automatic electric control box is insulating and waterproof. With automatic temperature control, the system will warm up automatically to the setting temperature. When vulcanizing time's up, the control box will ring an alarm and automatically switch off the power. In addition, the control box can monitor the temperature of 3-5 different points on each heating platen at the same time to ensure the result of jointing.

Product advantages

Antai ZLJ Pressure Bag pressure system

Old Type Pressure Platen

Simple structure no splice, long lasting The metal plate and the rubber are mechanically connected by bolts

Save 75% weight than the old type Heavy weight difficult to move

Flexible rubber provide uniform pressure Metal plate strain is limited

60% less ineffective pressure area of old model Bolts connect area have no effective pressure

Antai Heating Plate

* Flexible rubber heating element, provide uniform *temperature

* Sample structure,less failure

* 40% less weight and much thinner than the old model

* Save heating and cooling time

Old Model Heating Plate

*Separate resistance heating element

*Lots wiring, it is difficult to control the failure rate, Leakage hazard*Heavy and thick

*Hard to heat and cool

Machine Details

Host Structure

1. Frame 2.Set bolt 3.Upper heating platen 4.Down heating platen 5. Protecting board for pressure bag 6.Pressure bag 7. Protecting board for pressure bag 8.Insulation board 9. Fast cooling system 10.Customizable socket

ZLJ sectional vulcanizing press can be used by one set or several sets joint together for multiple combinations which is according to the size of the belts. The main parts of a single vulcanizing machine as below:

|

Name

|

Amount

|

|

The whole machine

|

1

|

|

Ratchet wrench

|

2

|

|

steel pad

|

1

|

|

Clamping device

|

1

|

|

Electric control box

|

1

|

|

Power cable

|

1

|

|

Control cable

|

2

|

|

Thermal resistance

|

2

|

|

QL electric water pump

|

1

|

|

SD Hand pressure pump (Optional)

|

1

|

|

Pressure pipe

|

2

|

|

Water cooling system (Optional)

|

1

|

Terms of Payment: TT (30% deposit, 70% balance be paid against the copy of bill of lading), L/C, etc.

Delivery deadline: Usually in 15 days

Package: Fumigation-free wooden case and packaging fumigation proved board for export transportation.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate