- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

5000 - 6000

-

Positioning Accuracy (mm):

-

0.005(XYZ) 0.001RAD(A)

-

Place of Origin:

-

China

-

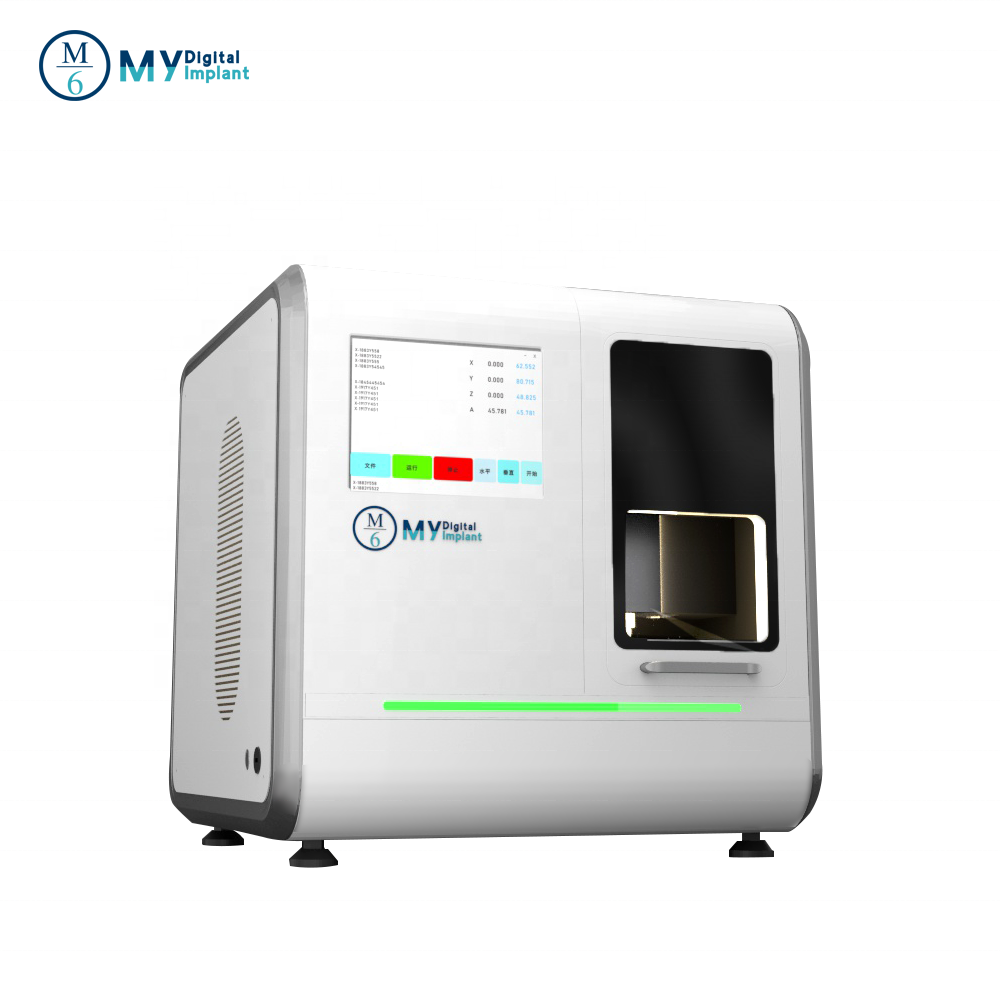

Brand Name:

-

M6

-

Voltage:

-

single phase, AC220V, 50Hz

-

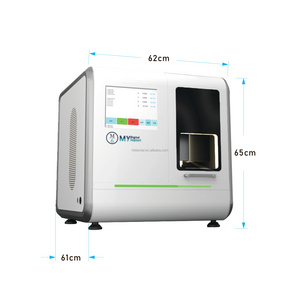

Dimension(L*W*H):

-

600x600x630

-

Weight (KG):

-

135

-

Spindle Motor Power(kW):

-

1.8

-

Max. Table Load(kg):

-

100 kg

-

Product name:

-

Dental Milling Machine

-

Spindle speed:

-

5000-6000rpm

-

Precision:

-

±0.005mm(XYZ),±0.001rad(A)

-

Travel for X, Y, Z axis:

-

110mm(X),135mm(Y),75mm(Z)

-

Processing:

-

customized abutment, emax material

-

machine size:

-

600x600x630mm

-

weight:

-

135kg

-

Model:

-

wet milling only

-

axis number:

-

4axis

-

spindle:

-

1.8kw

Quick Details

-

Table Travel (X) (mm):

-

110

-

Table Travel (Y) (mm):

-

135

-

Table Travel (Z) (mm):

-

75

-

Range of Spindle Speed(r.p.m):

-

5000 - 6000

-

Positioning Accuracy (mm):

-

0.005(XYZ) 0.001RAD(A)

-

Place of Origin:

-

China

-

Brand Name:

-

M6

-

Voltage:

-

single phase, AC220V, 50Hz

-

Dimension(L*W*H):

-

600x600x630

-

Weight (KG):

-

135

-

Spindle Motor Power(kW):

-

1.8

-

Max. Table Load(kg):

-

100 kg

-

Product name:

-

Dental Milling Machine

-

Spindle speed:

-

5000-6000rpm

-

Precision:

-

±0.005mm(XYZ),±0.001rad(A)

-

Travel for X, Y, Z axis:

-

110mm(X),135mm(Y),75mm(Z)

-

Processing:

-

customized abutment, emax material

-

machine size:

-

600x600x630mm

-

weight:

-

135kg

-

Model:

-

wet milling only

-

axis number:

-

4axis

-

spindle:

-

1.8kw

Product Paramenters

|

Size

|

610(W)x610(L)x630(H)mm

|

|

Weight

|

135KG

|

|

Travel

|

110mm(X),135mm(Y),75mm(Z)

|

|

Tilt angle

|

360°(A)

|

|

Power supply

|

Singe phase,AC 220V,50Hz

|

|

Max Power

|

2.8KW

|

|

Air pressure

|

6 bar and above

|

|

Drive motors

|

servo motor

|

|

Position Precision

|

±0.005mm(XYZ),±0.001rad(A)

|

|

Number of axes

|

4

|

|

Spindle power

|

1.8KW

|

|

Spindle speed

|

5000~60000rpm

|

|

Max feeding rate

|

6000mm/min(XYZ)

|

|

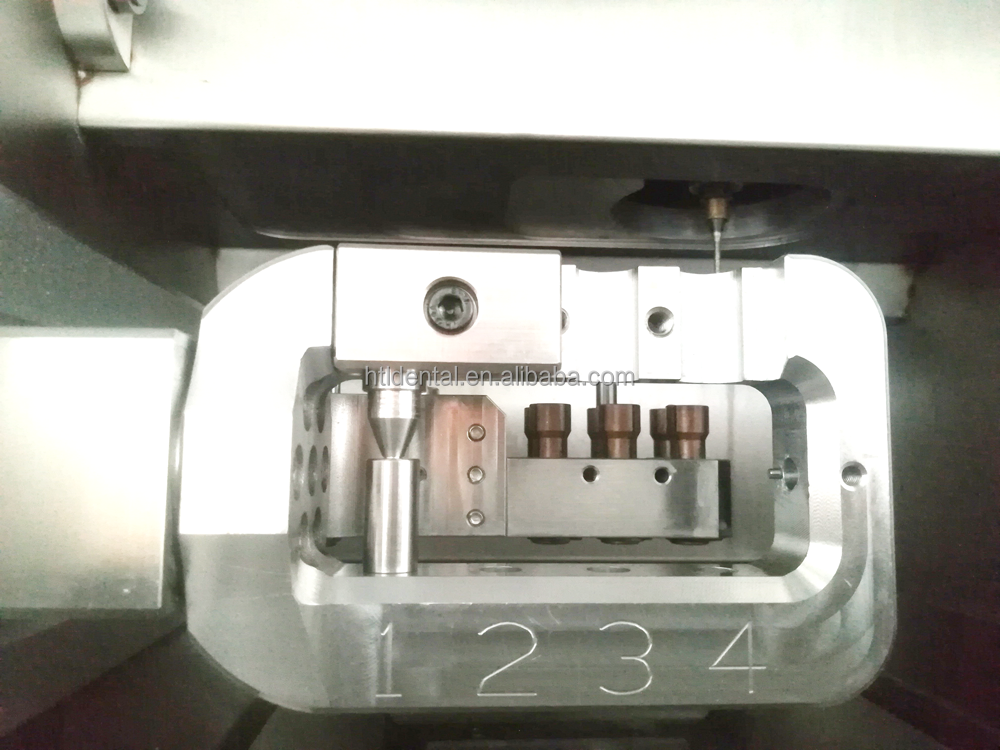

Milling bur positions number

|

6

|

|

Milling bur handle diameter

|

6mm

|

|

Milling bur length

|

50±1mm

|

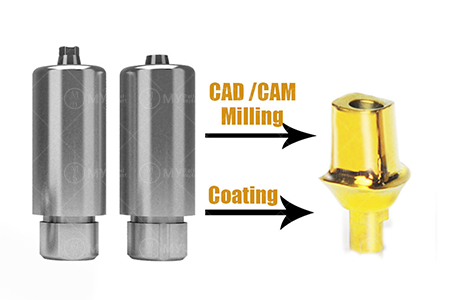

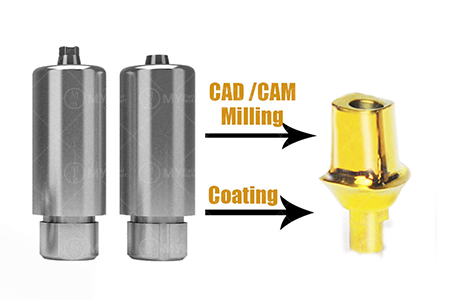

Millable material & products

1. titanium premilled blanks

Customized abutment

2. Emax material

could mill emax crown, veneer,inlays and onlays

Holder for titanium premilled blanks

Holder for Emax block

Two ways to lock the blanks to mill

1. only lock with holder

2. lock with holder and reverse jig

reverse jig

lock the blanks with reverse jig, could get linkage-less custom abutment,no need to rescan to design crown, save time

Precision

Milling bur to process titanium blanks

process the blanks with different size milling bur, make sure to get the most precise customized abutment

Milling bur to process emax material

Three different size milling bur to process emax products

Milling time

it will cost 15~20min to mill a job

Nest software

Millbox nesting software

Original Millbox comes with machine

Nest the designed customized abutment/crown in Millbox

nest in Millbox and get .nc format file

language available

different language available for Millbox

CS

DE

EN-US

EN

ES

FR

HU

IT

JA

KO

PL

PT-BR

RU

CH

Air pressure requirement

Air pressure should be ≥6bar

to make sure the machine could mill, we need to keep the air pressure above 6bar

Methods to send NC file from PC to Mill

Two ways to transfer NC file from computer to milling machine

1. via USB

2. via local area network

Packing and Shipping

After-sales Service

1. Machine installation guide

we will help you to install the machine step by step via video, and will check everything before formal milling

2. Millbox software installation and authorization guide

we will help you to install and authorize Millbox if you dont know how to do that

we will help you to set up right setting and parameter if you don't know how to do that

you could contact us if you meet any problem when using our machine, our team will help

Hot Searches