- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-062

-

Delivery Time:

-

5-7 days

-

MOQ:

-

10 PCS

-

shape:

-

disc

-

size:

-

Customized Magnet Size

-

Casing:

-

Zinc, Color Zinc, Nickel etc

-

Max Working Temperature:

-

80-200C

-

Packing:

-

Magnetic Isolation Package

-

Lead Time:

-

5-7 days

-

Product Name:

-

Ndfeb Neodymium Magnet

-

Coating:

-

NiCuNi

Quick Details

-

Tolerance:

-

±0.05mm

-

Grade:

-

NdFeB Magnet+Zinc, Color Zinc, Nickel etc, N35-N52, 38M-48M, 35H-48H, 33SH-44SH, 30UH-35UH

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huajin

-

Model Number:

-

HJ-062

-

Delivery Time:

-

5-7 days

-

MOQ:

-

10 PCS

-

shape:

-

disc

-

size:

-

Customized Magnet Size

-

Casing:

-

Zinc, Color Zinc, Nickel etc

-

Max Working Temperature:

-

80-200C

-

Packing:

-

Magnetic Isolation Package

-

Lead Time:

-

5-7 days

-

Product Name:

-

Ndfeb Neodymium Magnet

-

Coating:

-

NiCuNi

Specification

Support

ODM / OEM , Free Samples Service

if in stock

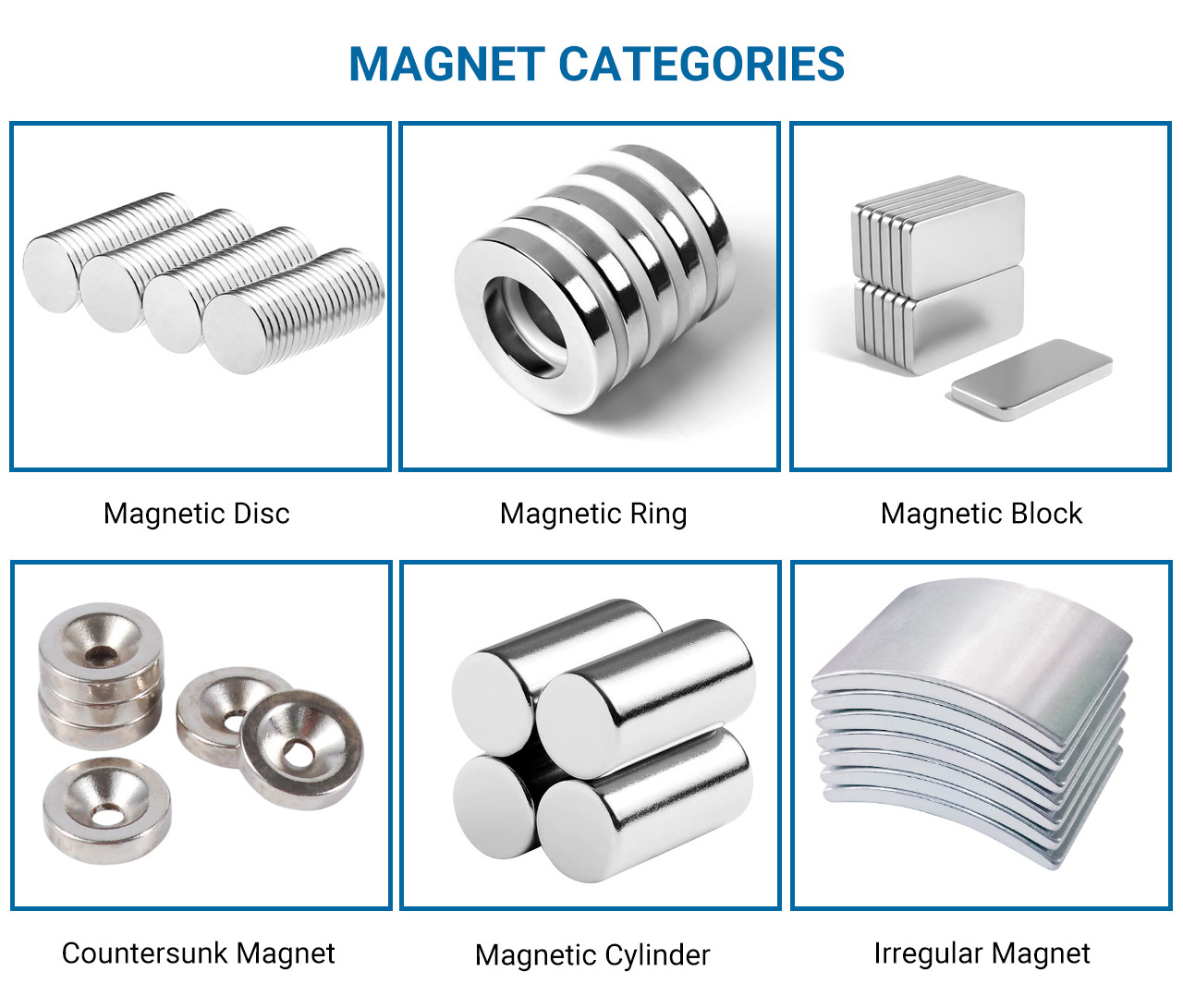

Support all Shape magnets , as long as you tell us the size or drawing you need, we can produce it!

|

Type

|

Permanent Sintered Neodymium Magnets / Rare Earth Magnet

|

|

Material

|

NdFeB

|

|

Shape

|

Block, Bar, Cube, Disc, Ring, Cylinder, Ball, Arc, Trapezoid, etc

|

|

Size

|

Customized according to customers’ requirements

|

|

Coating

|

Ni, Zn, Epoxy, Parylene, Gold, Passivated, etc

|

|

Density

|

7.5-7.6 g / cm³

|

|

Delivery date

|

2-4 days for common samples, 7-10 days for mass produciton

|

|

Magnetic Grade

&

Working Temperature

|

Magnetic Grade

|

Working Temperature

|

|

|

N35-N45

|

80 ℃ (176 ℉)

|

|

|

N48-N52

|

60 ℃ (160 ℉)

|

|

|

35M-52M

|

100 ℃ (212 ℉)

|

|

|

33H-50H

|

120℃ (248 ℉)

|

|

|

33SH-45SH

|

150 ℃ (302 ℉)

|

|

|

30UH-40UH

|

180 ℃ (356 ℉)

|

|

|

28EH-38EH

|

200℃ (392 ℉)

|

|

|

28AH-33AH

|

220 ℃ (428 ℉)

|

Magnet Categories

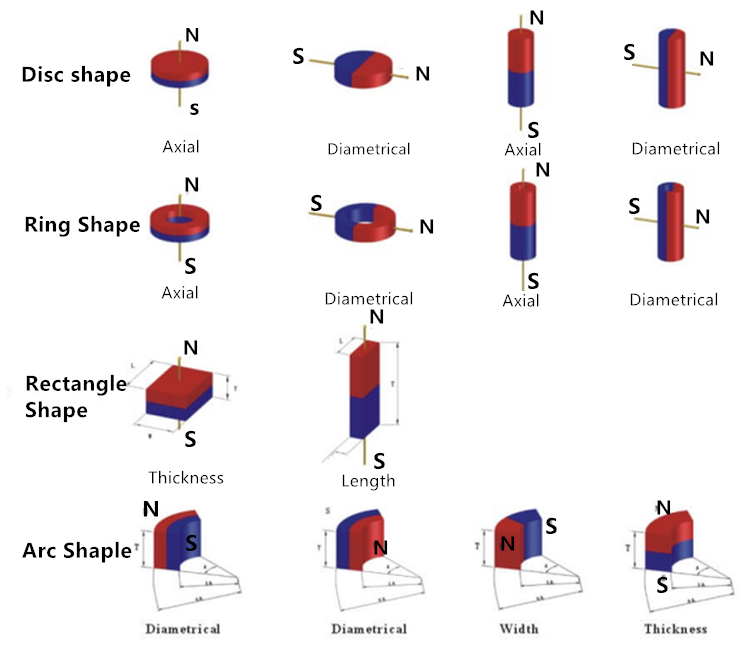

Magnetization Direction

Common direction of magnetization showed in picture bellow:

1> Disc, cylinder and Ring shape magnet can be magnetized Axially or Diametrically.

2> Rectangle magnets can be magnetized through Thickness, Length or Width.

3> Arc shape magnets can be magnetized Diametrically, through Width or Thickness.

Special direction of magnetization can be customized as required.

Grade/Coating

Support all magnet plating , like Ni-Cu-Ni, Zn, Epoxy , Gold, Silver etc.

2>

There are a variety of options for coatings, but nickel is the most common and usually preferred.

Our nickel plated magnets are actually triple plated with layers of nickel, copper, and nickel again. This triple coating makes magnets much more durable than the more common single nickel plated magnets.

3>

Other options of coating are zinc, tin, copper, epoxy,silver and gold.

Customer Feedback

Application

1). Electronics – Sensors, hard disk drives, sophisticated switches, electro-mechanical devices etc.;

2). Auto Industry – DC motors (hybrid and electric), small high-performance motors, power steering;

3). Medical – MRI equipment and scanners;

4). Clean Tech Energy – Water flow enhancement, wind turbines;

5). Magnetic Separators – Used for recycling, food and liquids QC, waste removal;

6). Magnetic Bearing – Used for highly sensitive and delicate procedures in various heavy industries.

Hot Searches