- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Customize

-

Working Width:

-

250mm

-

Function:

-

Finger Joint Assembler

-

Type:

-

Semi- Automatic

-

Delivery:

-

45 days

-

Blade diameter:

-

150

-

Working Hight:

-

250

-

Usage:

-

Wood Finger Jointing Shaper

-

Max assembled length:

-

no limit

-

Application:

-

Wood Process

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

customer requirement

-

Weight (KG):

-

3500 KG

-

Color:

-

Customize

-

Working Width:

-

250mm

-

Function:

-

Finger Joint Assembler

-

Type:

-

Semi- Automatic

-

Delivery:

-

45 days

-

Blade diameter:

-

150

-

Working Hight:

-

250

-

Usage:

-

Wood Finger Jointing Shaper

-

Max assembled length:

-

no limit

-

Application:

-

Wood Process

250mm Semi Automatic FJ Line Finger Joint Shaper And Press Machine

Characteristics

the machine integrates trimming,milling teeth,waste crushing and deburring and other functions into one,trimming,

deburring,crushing device and cutting blades are directly fixed to the motor,the cutting position can be adjusted to ensure the verticality of cross-section.

the dual high-speed shaft for milling teeth can be adjusted up or down according to actual requirement;the high-speed spindles applies accurate dynamic balance and sealed oil bearings to ensure machining accuracy.

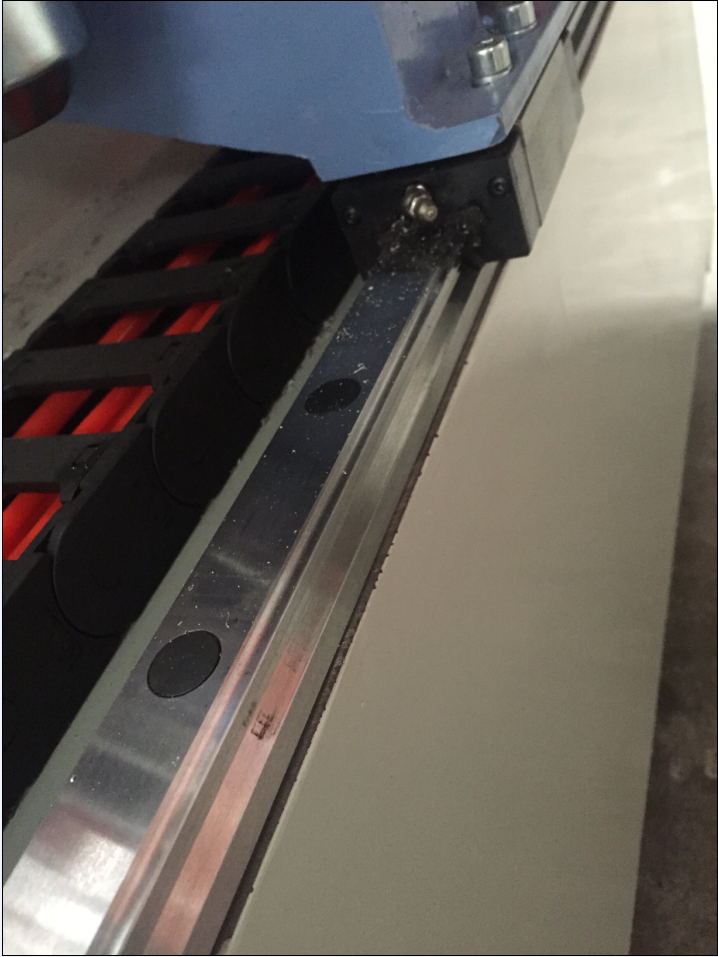

workbench of the machine adopts imported rails,bearings to make it run smoothly,rail,bearing has long service life,

the timber clamping device,using clamping and pneumatic sensor detection,making it safe and reliable.

the workbench is driven by hydraulic cylinder,travel speed can be individually adjusted, the forward speed is adjusted by one-way throttle valve mainly based on cutting amount;the backward includes rapid return and deceleration to smooth stop.additional material supporting device moving with the workbench,the machine has features of high efficiency and low labor intensity.

| Spindle use the SKF bearing which from Switzerland, we will Force analysis basic on the Stress point use double bearing.Cutter install point will use the Dia. 70mm. make sure the spindle firm and stable during the High speed rotation |

|

|

using ROUST Precision Linear slide Which is Germany technical, Precision in 0.02mm.Middle pre-press Linear slide design. In that can improve its Stability & Durability |

| Feeding belt use the worm gear reducer transmission. Small volume can Resist big Torsion . Transmission high Efficient, with high range reduce speed .with special design reduce Noise. |

|

|

-DETAL PLC with high operation speed. Normal Instruction only cost 0.22US , mory storage 26K.

-servo Dirver: DETAL. Servo motor: Detal With high transmission and speed.

|

|

|

High decomposition optical encoder, difference from normal encoder. - Photoelectric sensor: use Panasonic sensor from Japan. with Infrared visible light, easy adjust .with the Background suppression function .collect Distinguish wooden color and Wood scarring. |

|

| Teeth protect system: can avoid damage the last wood stick was processed finger joint cutter processing | |

| Glue application system: use the profile teeth dip in type. make sure the glue can full of the wood. (Normal standard is 12*4mm, special can make fit for Customer request) | |

| Oil-water separator: make sure the air compressor dry. | |

|

-hydraulic system use Clogging pump hydraulic valve . --Use air-cooled to cool the oil Temperature. avoid hydraulic system long time working. |

|

|

|

Inside boards use the Linear guide rail, make sure the board linear.

In the same time avoid glue dry block feeding. |

1.MXB3525 Finger joint shaper

|

Max. working width |

500mm |

|

Max. working high |

250mm |

|

Shaper spindle speed |

6500r/min |

|

cut-off saw speed |

2800r/min |

|

Shaper spindle diamter |

70mm |

|

Cutting-off saw blade diamter |

350 mm |

|

Scoring saw diamter |

150 mm |

|

working table size |

700×650mm |

|

Main saw motor power |

15KW * 2sets |

|

Cutting-off motor power |

5.5KW |

|

Scoring motor power |

0.75KW |

|

Hydraulic system power |

2.2KW |

|

Hydraulic system pressure |

1-3MPa |

|

air pressure request |

0.6 Mpa |

|

Net weight |

1600KG |

|

overall dimension |

3292×1510×1595mm |

2.MHZ15L finger joint Press

CHARACTERISTICS:

Advanced technology:This machine is characterized by human-machine interface,numerical control technique,optical,mechanical,electronic and hydraulic integration.

According to preset data,measuring,feeding, pre-jointing,correcting,jointing and cutting, all procedures work in turn automatically.

High efficiency:Pre-jointing,adjustable feeding speed and jointing program ensure a high efficiency.

Steady quality:Correcting program hit the joints flat, and jointing power is adjustable which ensure the enough flatness and strength

Safety and Security:Reasonable and humanized design ensure the safety and security.

|

MHZ15L Finger Jointer Press |

|

|

Max. working width |

250mm |

|

Max. working thickness |

75mm |

|

Working length |

No limit |

|

Max. feeding speed |

36m/min |

|

Saw diamter |

400 mm |

|

Cutting motor power |

2.2KW |

|

Feeding motor power |

0.75KW |

|

Pump motor power |

5.5KW |

|

Total power |

8.45Kw |

|

Air pressure |

0.6 ~ 0.7Mpa |

|

Rated hydraulic pressure |

10Mpa |

|

Net Weight |

4800KG |

|

overall dimension |

13000×2500×1650mm |

MAYBE YOU ALSO NEED