- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM/ODM

-

Name:

-

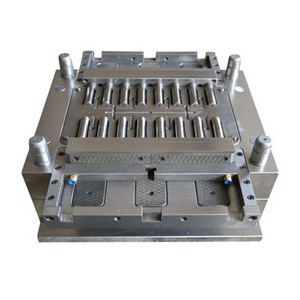

Roto molding mould fishing kayak with single seat aluminum boat mold

-

Mould material:

-

Aluminium

-

Plastic product material:

-

LLDPE, MDPE and HDPE

-

Cooler mould lead time:

-

15--60 days

-

Design software:

-

AutoCAD, UG, Solidworks, PROE

-

Mould life:

-

Ten thousand cycles

-

Surface treatment:

-

Mirror Polishing, Sand Blasting, Customized

-

Color and Size:

-

Customized

Quick Details

-

Shaping Mode:

-

Sand casting

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Customized

-

Model Number:

-

OEM/ODM

-

Name:

-

Roto molding mould fishing kayak with single seat aluminum boat mold

-

Mould material:

-

Aluminium

-

Plastic product material:

-

LLDPE, MDPE and HDPE

-

Cooler mould lead time:

-

15--60 days

-

Design software:

-

AutoCAD, UG, Solidworks, PROE

-

Mould life:

-

Ten thousand cycles

-

Surface treatment:

-

Mirror Polishing, Sand Blasting, Customized

-

Color and Size:

-

Customized

|

Name: Roto molding mould fishing kayak with single seat aluminum boat mold

|

|

|

|

|||

|

Material of mold

|

Aluminium

|

|

|

|||

|

Material of products

|

LLDPE, LDPE, MDPE, HDPE

|

|

|

|||

|

Shaping model

|

Rotomolding

|

|

|

|||

|

Production process

|

Rotomolded cooler products making process is: filling material→heating the mould→cooling the mould→demolding→inspecting→packing

|

|

|

|||

|

After treatment

|

Common polishing, or sand blasting, or mirror polishing, or finishing the mould surface according to your requirements.

|

|

|

|||

|

Workflow

|

Checking drawing → Mould 3D drawing designing →Patten processing →Aluminum casting →Aluminum CNC processing → Mould assembling →Aluminum mould surface finishing

→Sample testing...

|

|

|

|||

|

MOQ

|

Rotomolded Cooler Mould MOQ: 1set, Rotomolded Cooler Product MOQ: 20pcs.

|

|

|

|||

|

Payment terms

|

T/T, 50% deposit in advance, balance before shipping

|

|

|

|||

Kayak Mould

|

In very general terms, the rotational molding process looks like this:

|

|

|

|

|||

|

Step1

|

Plastic raw material (typically in powder form) is placed inside a mold (cast aluminum, CNC machined aluminum)

|

|

|

|||

|

Step2

|

The mold is attached to an arm of a rotational molding machine, and enters the oven where it rotates (rotational molding) on two axes.

|

|

|

|||

|

Step3

|

As the plastic material melts, it begins to adhere to the inside mold walls, building wall thickness and taking on the shape and texture of the interior mold surface.

|

|

|

|||

|

Step4

|

After rotating in the oven, the mold enters the cooling phase, where the molten material eventually solidifies into the finished, hollow plastic part.

|

|

|

|||

|

Step5

|

The part is then removed from the mold, where it undergoes a variety of secondary operations (trimming, foam-filling, assembly, etc.) prior to shipment.

|

|

|

|||

Hot Searches