- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V / customized

-

Dimension(L*W*H):

-

according to design

-

Weight:

-

20000 kg

-

Name:

-

feed mill 15 ton/h cattle cow concentrate feed production line

-

Application:

-

feed mill and farms

-

Usage:

-

animal pellet and powder feed making

-

Motor:

-

Siemens Brand Avaiable

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Advantage:

-

High Capacity High Efficient

-

Color:

-

Clients' Requirement

-

Suit for:

-

Cow.sheep.goose.duck.chicken.etc

-

Capacity:

-

5-50 t/h

-

Keywords:

-

concentrate feed production line

Quick Details

-

Max. Capacity:

-

15 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

xinxiang hexie

-

Voltage:

-

380V / customized

-

Dimension(L*W*H):

-

according to design

-

Weight:

-

20000 kg

-

Name:

-

feed mill 15 ton/h cattle cow concentrate feed production line

-

Application:

-

feed mill and farms

-

Usage:

-

animal pellet and powder feed making

-

Motor:

-

Siemens Brand Avaiable

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Advantage:

-

High Capacity High Efficient

-

Color:

-

Clients' Requirement

-

Suit for:

-

Cow.sheep.goose.duck.chicken.etc

-

Capacity:

-

5-50 t/h

-

Keywords:

-

concentrate feed production line

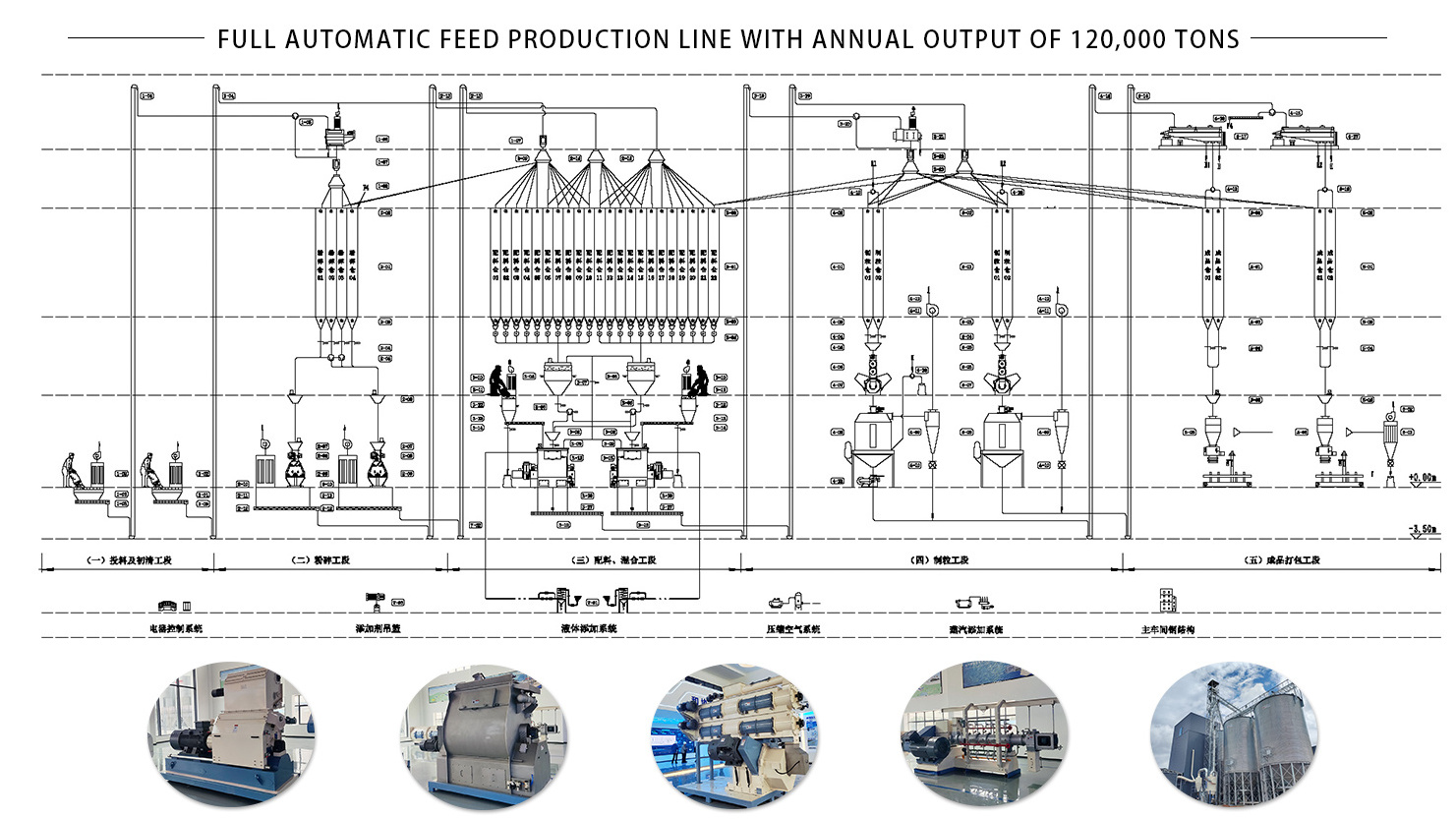

Livestock feed mill 15 ton/h cattle cow concentrate feed production line with corn silo

| Product name | Turnkey feed mill plant |

| Capacity | 5-50 ton per hour |

Animal feed production line can be used to make various poultry feed and aquatic feed for rabbits, ducks, cattle, chickens, sheep, pigs, pigeons, fishes and shrimp etc. The whole production line can be control by the automatic PLC control system.

1. Advantages of Feed Pellets:

1) Decreased ingredient segregation

2) Decreased feed wastage

3) Easy storage and transportation

4) Improved palatability

5) Reduced selective feeding

6) Destruction of pathogenic organisms

2. Raw Materials for Feed Pelletizing:

The feed pellets are usually made of corn, brown rice, paddy, sorghum and soybean meal etc.

3. Feed Pellets Processing Technology:

Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

a. For pig, the pellet diameter is usually ø3.5-6.5mm.

b. For cattle, the pellet diameter is usually ø4.5-8mm.

c. For chicken, pellet diameter is usually ø3.2mm.

d. For fish, pellet diameter is usuallyø2.0, ø2.5, ø3.0mm.

e. For shrimps, pellet diameter is usually ø1.0-ø3.5mm.

Pellet length is customized.

4. Equipment Related to Chicken Poultry Cattle Livestock Complete Animal Feed Line:

Feed Grinder →Feed Mixer → Feed Pellet Mill → Counterflow Cooler → Feed Pellets Crumbler → Feed Pellets Grading Sieve → Automatic Weighing and Packing Machine

1) Crushing Section

When the thickness of the raw material is >5 mm, the raw materials must be used for size reduction before the feedstock is sent to the hammer mill (crusher) to reach a diameter of less than 3 mm.

2) Mixing Section

Two open doors structure, discharge rapidly, no leakage, no residue. Multiform liquid adding system and can be matched with compressed air jetting system Suitable for mixing premix, poultry feed, aquatic feed, additives and chemical and medicine industries, etc

3) Pelletizing Section

Acting as the heart part of the whole processing line, ring die pellet mill through adjusting the rotational speed of screw feeder axis to obtain the suitable flow of material, through the enforced feeder, enter the pressing room to pelletize finally.

4) Cooling Section

After the pelletizing process, the temperature of the feed pellet is about 60-80 degrees Celsius, with a moisture content of about 15%. A Cooler must then be used to reduce the moisture content of the wood pellets to about 3-4%, thereby making the feed pellets easier to store.

5) Classifying screen

It is applicable for screening and classifying of mash or pellet feed. It is also can be used for cleaning of raw materials and classifyingof semi finished products after second grinding.

by large and medium feed mills.

6) Packing Section

After cooling and screening, the feed pellet must be protected from moisture and other environmental conditions. For this there is the packing process, which is effectively handled by our Semi-Auto Packing Machine.

Feed mill plant

Pellet feed making plant Powder feed making plant

Farms and small feed mill plant

Modular feed unit Flat die type feed production line

Grinding machine

Mixing machine

Single shaft mixer Double shaft mixer Stainless steel mixer

Pellet mill

Flat die pellet mill Ring die pellet mill Extruder

Auxiliary equipment