- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2200

-

Voltage:

-

220V/380V

-

Weight:

-

83 KG

-

Dimension(L*W*H):

-

1100*450*950mm

-

Marketing Type:

-

New Product 2024

-

Capacity:

-

500kg/h

-

Filter:

-

0.6mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Banglan

-

Processing Types:

-

orange vegetable and fruit

-

Power:

-

2200

-

Voltage:

-

220V/380V

-

Weight:

-

83 KG

-

Dimension(L*W*H):

-

1100*450*950mm

-

Marketing Type:

-

New Product 2024

-

Capacity:

-

500kg/h

-

Filter:

-

0.6mm

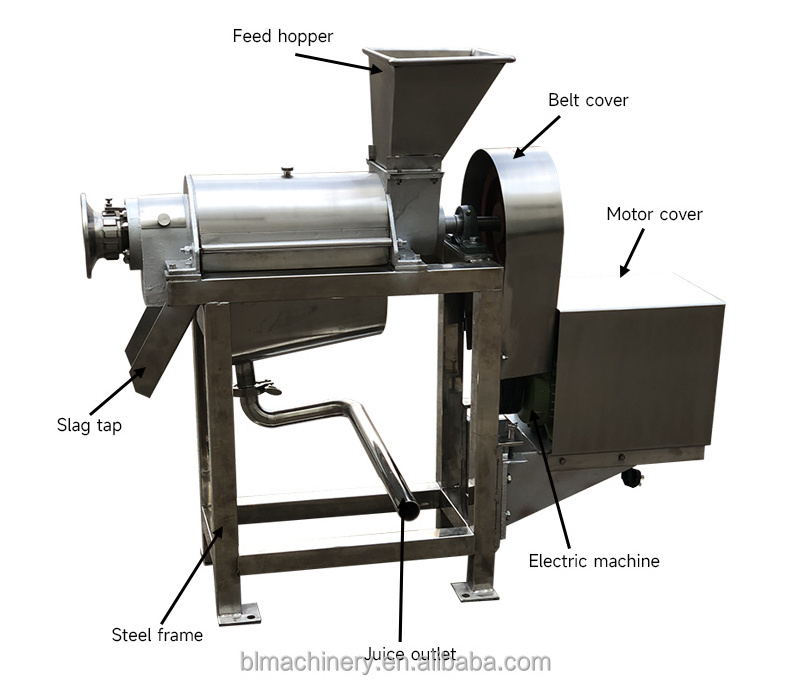

Commercial Pumpkin Vegetable Fruit Melon Processing Juice Extractor Spiral Juicer Extractor Juice Making Machine

Products Description

Fruit and vegetable juicing and pomace separation machine.

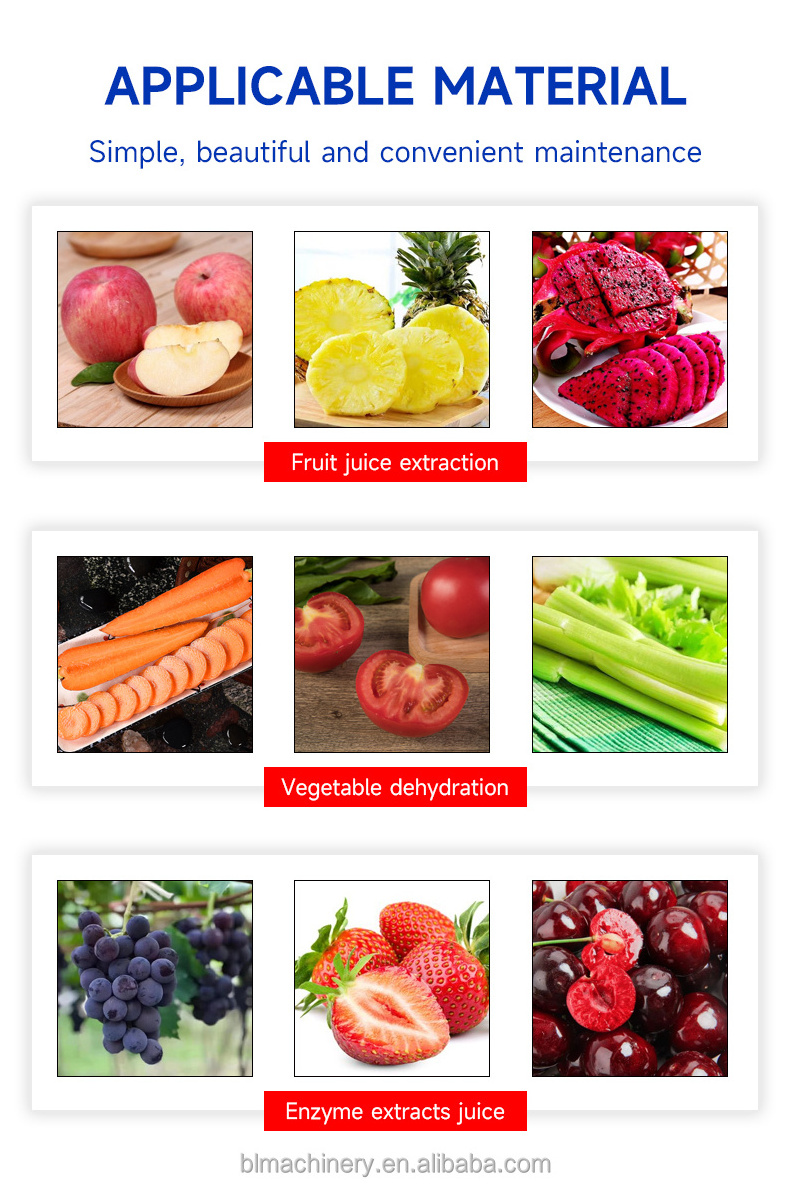

Fruits: juicing of apples, pears, pineapples, lemons, raspberries, blueberries, cantaloupe, watermelon, coconut, grapes, and other fruits.

Vegetables: juicing of ginger, garlic, onion, wheat seedlings, tomato, carrot, leek, cabbage, pumpkin, cucumber and other vegetables.

I. Structure:

It consists of front support, feeding hopper, screw, filter, juice container, rear support, slag tank and other parts, the main shaft of the screw is supported in rolling bearings, the right end is supported in the hand wheel bearings, and the motor drives the screw through a pair of triangular belt pulleys to do the work.

Ⅱ. The working principle:

The main component of this equipment is the spiral along the slag outlet direction of the bottom diameter gradually increased and the pitch gradually reduced, when the material is propelled by the spiral, due to the reduction of the volume of the spiral cavity, the formation of the material pressure.

Spiral spindle rotation direction from the feed hopper to the direction of the slag tank, for the clockwise direction.

Raw materials are added to the feed hopper and pressed under the propulsion of the screw, and its pressed juice flows into the juice container at the bottom through the strainer, while the waste material is discharged through the annular gap formed between the screw and the conical part of the regulator, and the movement of the regulator head along the axial direction can adjust the size of the gap. Used for clockwise (from the equipment of the slag tank to the feed hopper end of the rotary hand wheel shaft bearing seat, the regulator head to the left, the gap that is narrowed, and vice versa, the gap becomes larger.) Change the size of the gap, that is, adjust the resistance of slag discharge. Can change the rate of dregs, but if the gap is too small, in the strong extrusion, part of the slag particles will be squeezed through the filter together with the juice, despite the increase in the juice, but the quality of the juice is relatively lower, the size of the gap should depend on the user's specific process requirements.

Product parameters

|

Model

|

BL0116

|

|

External Dimensions

|

1100*450*950MM

|

|

Voltage and power

|

220V/380V/50HZ

|

|

Capacity

|

500KG/H

|

|

Wattage

|

2.2KW

|

|

Filter

|

0.6MM

|

|

Weight

|

83KG

|

Product details

Hot Searches