- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Bridge

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAIYU

-

Model Number:

-

Customized

-

Product name:

-

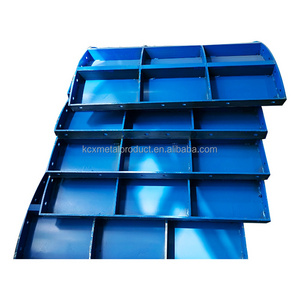

construction bridge project precast segmental box girder steel

-

Keywords:

-

precast segmental box girder steel

-

Color:

-

Customized

-

Size:

-

Customized

-

MOQ:

-

10 tons

-

Weight:

-

Customized

-

Length:

-

Customized

-

DELIVERY TIME:

-

60day

-

Name:

-

Bridge Mold

-

Brand:

-

HAIYU

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Installation, Other

-

Project Solution Capability:

-

Others

-

Application:

-

Bridge

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAIYU

-

Model Number:

-

Customized

-

Product name:

-

construction bridge project precast segmental box girder steel

-

Keywords:

-

precast segmental box girder steel

-

Color:

-

Customized

-

Size:

-

Customized

-

MOQ:

-

10 tons

-

Weight:

-

Customized

-

Length:

-

Customized

-

DELIVERY TIME:

-

60day

-

Name:

-

Bridge Mold

-

Brand:

-

HAIYU

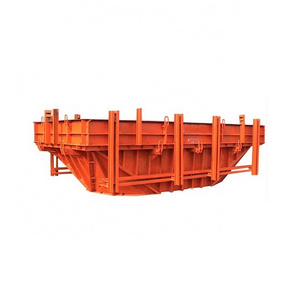

What is precast segmental box girder

The bridge viaduct is divided into small segments, that are prefabricated in the good quality control casting yard, then,

delivered to install by good erection equipment.

delivered to install by good erection equipment.

Advantages and Benefits

1. Construction Simplicity

• easier installation of external post-tensioned tendons

2. Time Savings/Cost Effectiveness

• precast segment to be prefabricated and stored at casting yard while foundation and sub-structure are being built.

• by using efficient erection method and equipment, the rapid installation of viaduct can be achieved.

3. Quality Control Q - A/QC

• precast segment to be produced in factory-manner condition w/ good quality control.

• minimum interruption natural impacts such as bad weather, rain.

• minimum waste of material

• good precision in production

4. Inspection and Maintenance

• external prestressing tendons can be easily inspected and repaired if required.

• maintenance program can be scheduled.

• easier installation of external post-tensioned tendons

2. Time Savings/Cost Effectiveness

• precast segment to be prefabricated and stored at casting yard while foundation and sub-structure are being built.

• by using efficient erection method and equipment, the rapid installation of viaduct can be achieved.

3. Quality Control Q - A/QC

• precast segment to be produced in factory-manner condition w/ good quality control.

• minimum interruption natural impacts such as bad weather, rain.

• minimum waste of material

• good precision in production

4. Inspection and Maintenance

• external prestressing tendons can be easily inspected and repaired if required.

• maintenance program can be scheduled.

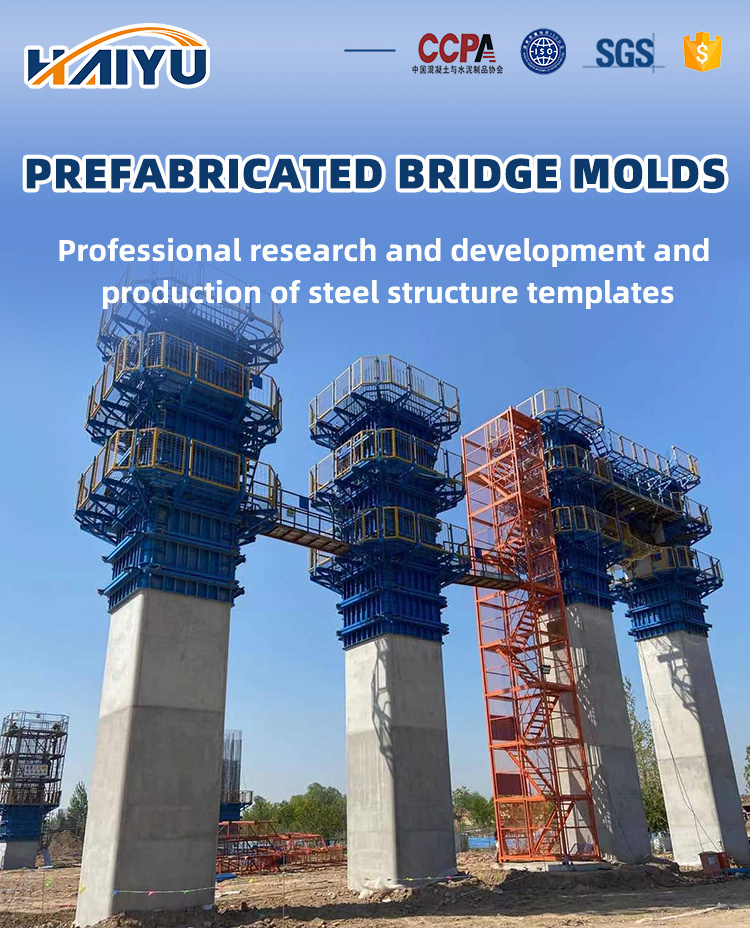

ramp bridge etc. It is used for concrete Colunm Pier Casting in situ, common shapes are: top round pier, cone pier, Y shape pier,

hyperbola pier, vase shape pier, linear shape pier, V shape pier, rectangle pier and other speacial shape etc.

According to the shape of Pier Formwork, these formworks are always devided into two types:

1. General type (Cross Section Shape: Circle, Square, rectangle, Oval)

2. Special type (Cross Section Shape: Curved, Parabolic, other special design)

Features of General Type and Special Type :

Gerneral Type: Nice Universality, Good economic benefit, High reusable rate, Short lead time.

Special Type: Attractive Appearance, Specially Designed for Certain Application, Longer lead time with higher costs.

For the Pier Fromwork of special type, there are 3 common shapes widely applied in the bridge constructions :

A. Hyperbolic Pier Formwork : Used in road bridge, railway bridge, flyover, ramps, etc.

B.

Portal Pier Formwork

: Used in road bridges, railway bridges, such as: Double-Pier, Triple-Pier, Multi-Pier.

C.

Corbel Pier Formwork

: Used in freight railway bridges, including pier body and pier cap forms.

Hot Searches