Introduction

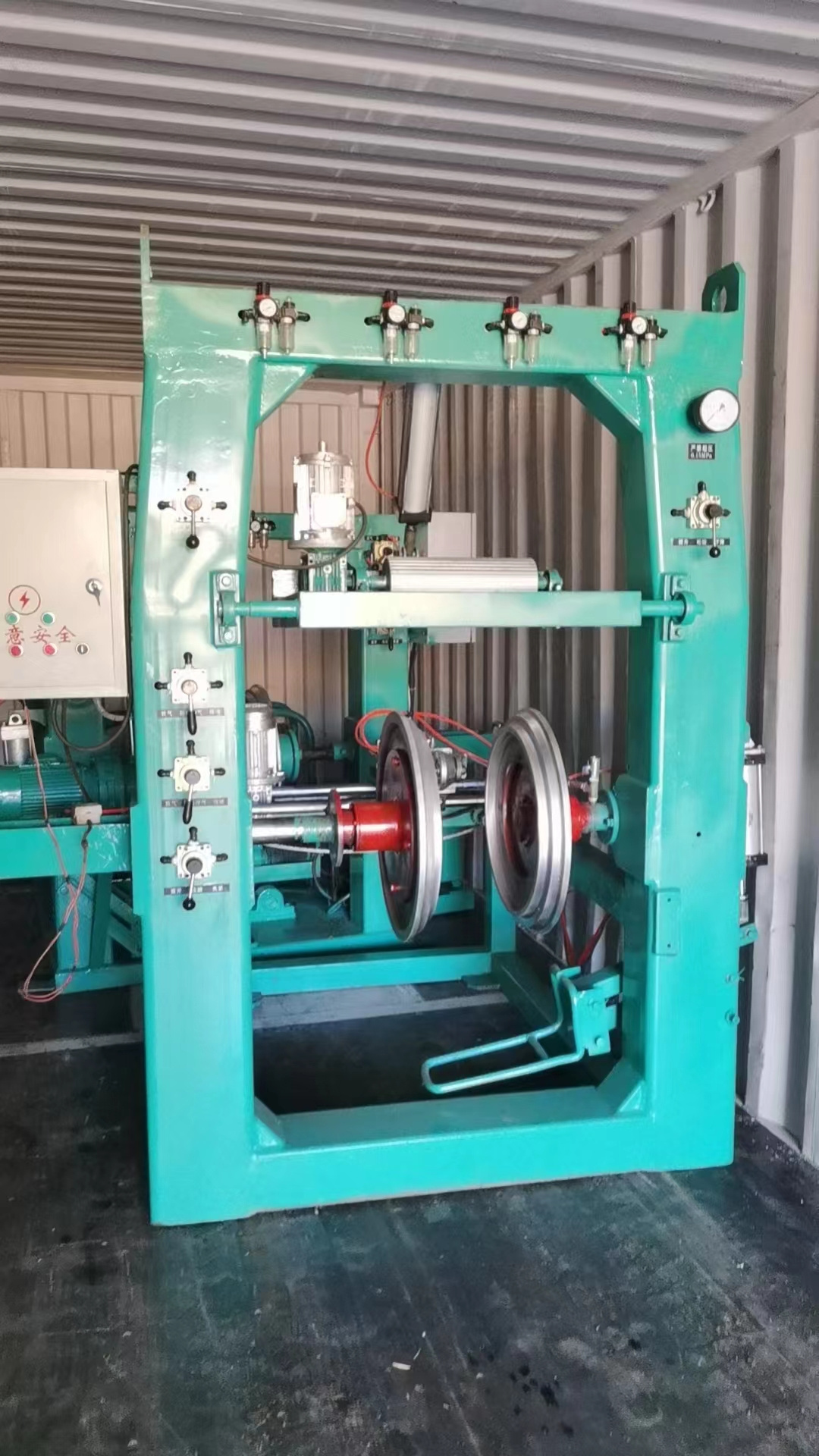

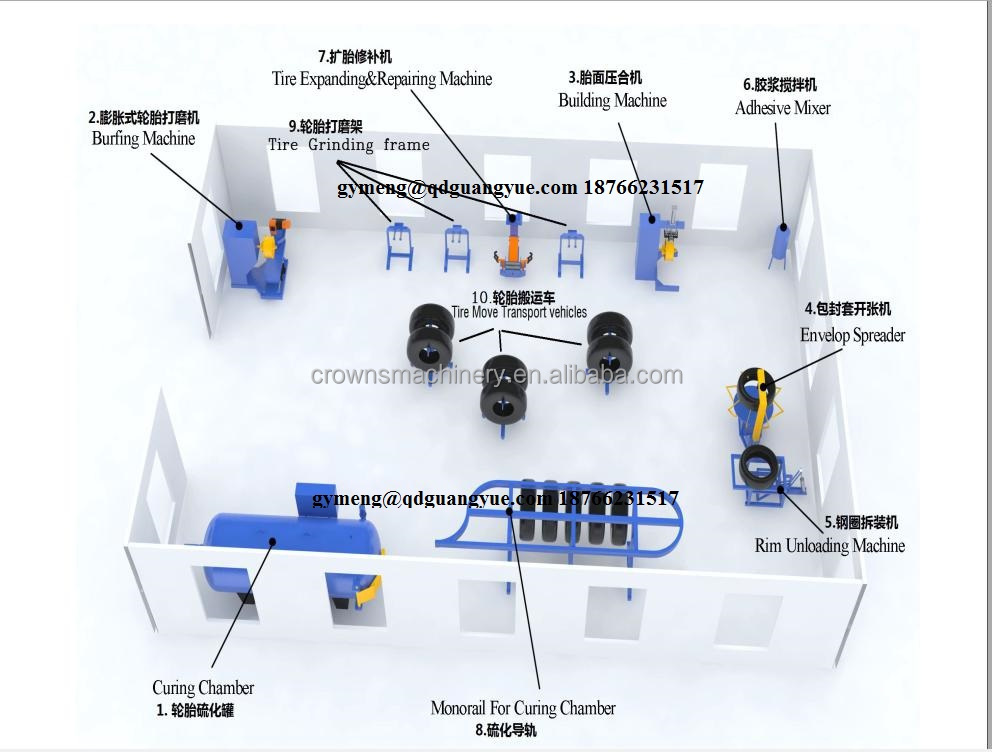

The tire buffing machine, also known as a tire retreading machine or tire buffer, is a piece of equipment used in the tire retreading industry. Tire retreading is a process in which old or worn-out tire casings are refurbished to extend their lifespan and reuse them. This is a cost-effective and environmentally friendly alternative to manufacturing entirely new tires.The primary purpose of a tire buffing machine is to remove the worn-out or damaged tread rubber from the tire's casing.

Working Process Of Buffing

Preparation

: The old tire is inspected to identify areas of wear or damage. Any loose or damaged tread rubber is removed manually before the tire is placed on the buffing machine.

Mounting

: The tire is mounted onto the machine's rotating spindle. It is secured in place to ensure stability during the buffing process.

Buffing

: The machine's buffing head or drum, which contains abrasive materials like grinding stones or carbide blades, is brought into contact with the tire's tread surface. It rotates and removes a controlled amount of the old tread rubber to create a smooth and even surface.

Quality control

: During the buffing process, operators may use various instruments to monitor the depth of the buffing and ensure that it is uniform across the tire.

Inspection

: After buffing, the tire is carefully inspected for any remaining damage, such as punctures or structural issues. If any defects are found, they are repaired before proceeding further.

Building and curing:

Once the buffing is complete and the tire is deemed suitable for retreading, a new layer of tread rubber is applied to the prepared casing. The tire is then placed in a curing chamber where heat and pressure are applied to bond the new tread to the casing.