- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+/_5ml

-

Voltage:

-

AC Three-Phase 380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Gofar

-

Dimension(L*W*H):

-

3000*1500*2500

-

Weight:

-

500 KG

-

Keywords:

-

viscous liquid Filling Machine/oil bottle filler

-

After-sales Service Provided:

-

Video Technical Support Online

-

After Warranty Service:

-

Non - Man-made Damaged Parts

-

Usage:

-

High viscous Liquid Products

-

Product name:

-

Liquid shampoo paste oil Filling Machine

-

Function:

-

Viscous paste oil shampoo Filling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Machine material:

-

Stainless Steel SUS 304/316

-

Name:

-

High Viscosity Fluid Filling Machine

Quick Details

-

Machinery Capacity:

-

1000BPH, 100BPH, 200BPH, 600-800BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Oil, shampoo,hand soap liquid,washing gel, ketchup, sauce,paste

-

Filling Accuracy:

-

+/_5ml

-

Voltage:

-

AC Three-Phase 380V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Gofar

-

Dimension(L*W*H):

-

3000*1500*2500

-

Weight:

-

500 KG

-

Keywords:

-

viscous liquid Filling Machine/oil bottle filler

-

After-sales Service Provided:

-

Video Technical Support Online

-

After Warranty Service:

-

Non - Man-made Damaged Parts

-

Usage:

-

High viscous Liquid Products

-

Product name:

-

Liquid shampoo paste oil Filling Machine

-

Function:

-

Viscous paste oil shampoo Filling

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Machine material:

-

Stainless Steel SUS 304/316

-

Name:

-

High Viscosity Fluid Filling Machine

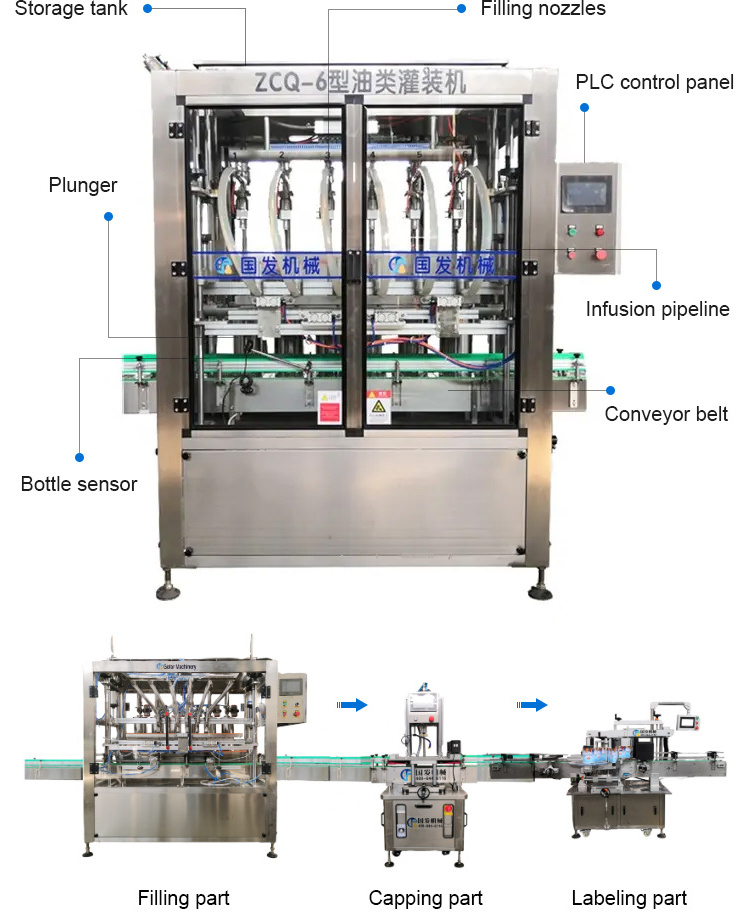

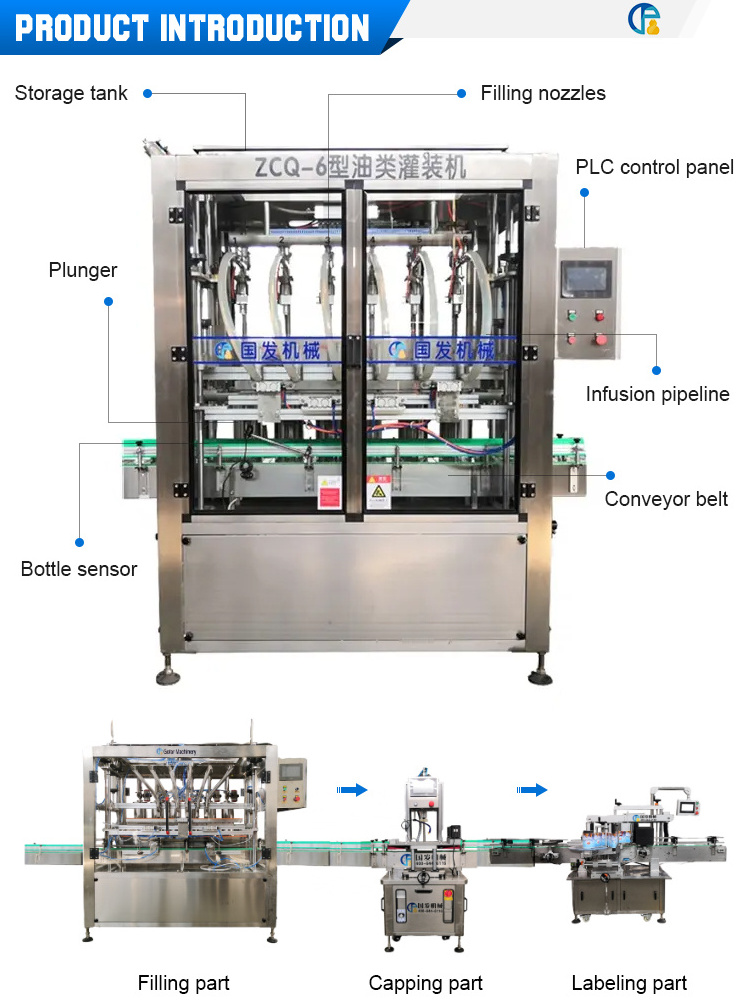

Fully automatic high quality edible olive cooking lubricant oil filling production line

High quality automatic olive oil lubricant bottle filling machine consists of plunger

filling machine, sealing machine and labeling machine, which is one of the best

selling production lines in our company.

Automatic high quality shampoo tomato paste sauce bottle filling machine

In food industry like edible oil, yogurt, tomato paste, chilli sauce, honey, butter, ketchup lunch meat etc.

In cleaning liquid and cosmetic industry, like shampoo, liquid soap, hand sanitizer, laundry detergent, shower gel, cream, lotion, hair gel, etc.

In car products industry, like motor oil, lube oil, antifreeze, brake fluid, fuel additive, screen cleaning liquid etc

In pharmaceutical industry, like syrup, oral liquid , alcohol etc.

The machine can be made with 4 filling heads/ 6 filling heads/ 8 filling heads/ 10 filling heads/ 12 filling heads ,16 filling heads, 18 filling heads etc, according to the filling capacity

Product details

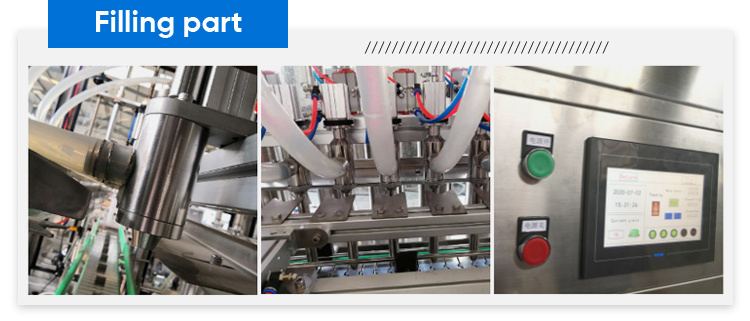

1.

Filling machine using piston type principle, linear arrangement, filling different volume

by simply adjusted.

2.

Special silicone hose, with professional solenoid valve and stainless steel filling nozzle,

filling volume is accurate, rust resistant and durable.

3.

Adopt touch screen PLC control, use brand electrical components, reliable quality.

4.

Can be combined into filling machine production line according to your needs.

1.

Intelligent touch screen control, automatic induction screw cap, linear improvement of

production efficiency.

2.

Humanized design, suitable for a variety of bottle screw cap, strong versatility.

3.

Tighten the cap, no leakage, good customer experience.

4.

Can be combined into filling machine production line according to your needs.

1.

PLC control, large-scale man-machine interface, multiple sets of labeling parameter

memory, can quickly replace products.

2.

The whole machine is stainless steel and anodized aluminum is made of high-level,

meet the GMP standard.

3.

The machine has the functions of bottle guide, bottle separation, loss of mark, counting

and so on. The height of the label position is adjustable.

|

Filling Material

|

High viscous liquid like Oil/paste/shampoo

|

|

Filling Accuracy

|

+/_5ml

|

|

Keywords

|

High viscous liquid Filling Machine

|

|

After-sales Service Provided

|

Video Technical Support

|

|

After Warranty Service

|

Non - Man-made Damaged Parts

|

|

Product name

|

High viscous Liquid Filling Machine

|

|

Bottle type

|

PET Plastic Bottle Glass Bottle

|

|

Filling type

|

Piston Cylinder

|

|

Machine material

|

Stainless Steel SUS 304/316

|

This machine is suitable for ketchup, chili sauce, facial cleanser, hand sanitizer, washing

powder, gel, face cream, toothpaste,etc. It can automatically complete bottle washing,

filling and capping.

Qingzhou Gofar Packaging Machinery Co.,Ltd is a professional manufacturer engaged in the research, development, production, sale and service of Bottle washing machine;Filling machine;Sealing machine;Labeling machine; Water treatment machine.The company was established in 20 12 years, has many famous enterprises at home and abroad to establish a long-term friendly business relationship.

We are located in WEIFANG,SHANDONG PROVINCE,CHINA. with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including laser cutting machine\ CNC tapping machine \machining center.

In addition, we have obtained I S O 9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as AFRICA ,SOUTH ASIA. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

Business strictly in accordance with relevant state laws, regulations and rules of the WTO requirements management according to law, actively participate in regional economic cooperation. My company will expand the scale of operation and steady development of corporate Packaging Machinery, sincerely seeking partners and common development.

Our Advantages

01 POWERFUL FACTORY

10 Years Manufacturing Experiences & 8 Years Exporting Experiences, not reseller, not tradingcompany.

02 ODM&OEM

Customized solutions are supported.

03 PROFESSIONAL TEAM AND SUPERIOR SERVICEH

Have an professional team and the staff will have be trained regularly.

04 REASONABLE PRICE

Easy operation, positioned accuracy, reasonable price.

05 QUALITY ASSURANCE

Improve your working efficiency and help you resolved the problem of difficult employment and high labor costs.

06 ONLINE INSTRUCTION

Online conferences product explanation, technical guidance, factory inspection etc are supported.

07 AFTER-SALES SERVICE

The job site installation, training, guidance are supported.The staff will have be trained regularly.

Certifications

We have passed :sealing machine CE certification, filling machine CE certification, ISO9001,SGS and other certification, to ensure the quality of products.

Exhibition

Packing &Shipping

The machine is packed in polyethylene film, then in export wooden cases to protect the machine from impact and friction, the size of the package depends on the machine. We cooperate with senior freight forwarders to ensure that the machine can reach you in the shortest time.

FAQ

Q1.How long will take for the delivery of product?

10 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,usually about 20~30 days.

Q2

.

What's the insurance of after-sale service after purchase?

All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable. One year warranty service for all machine, please feel free to contact us if you have any questions.

Q3.When the machine arrives at the work site, is it easy to install?

How to solve the problem of quick installation and use?

All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Q4:During the use of the machine, how to get after-sale service?

We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q5:Will the accessories change frequently with machine?

The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.

Hot Searches