This water treatment system is made by the

raw water tank through the pretreatment to

reverse osmosis desalting device to get pure

water. Pretreatment is by silica sand filter,

activated carbon filter, sodium ion exchanger

and the precision filter composition. The

reverse osmosis device the core parts adopt

the world famous water pump and reverse

osmosis RO membrane.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sky Machine

-

Dimension(L*W*H):

-

2800*2230*2700mm

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Packaging:

-

Bottle

-

Control System:

-

PLC Touch Screen

-

Filling Principle:

-

Atmospheric Pressure

-

Bottle Volume:

-

150ml to 2l

-

Electric Brand:

-

Siemens, Mitsubishi

-

Function:

-

Washing Filling Capping

-

Capacity:

-

3000BPH

Quick Details

-

Machinery Capacity:

-

8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Juice

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sky Machine

-

Dimension(L*W*H):

-

2800*2230*2700mm

-

Weight:

-

4800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Packaging:

-

Bottle

-

Control System:

-

PLC Touch Screen

-

Filling Principle:

-

Atmospheric Pressure

-

Bottle Volume:

-

150ml to 2l

-

Electric Brand:

-

Siemens, Mitsubishi

-

Function:

-

Washing Filling Capping

-

Capacity:

-

3000BPH

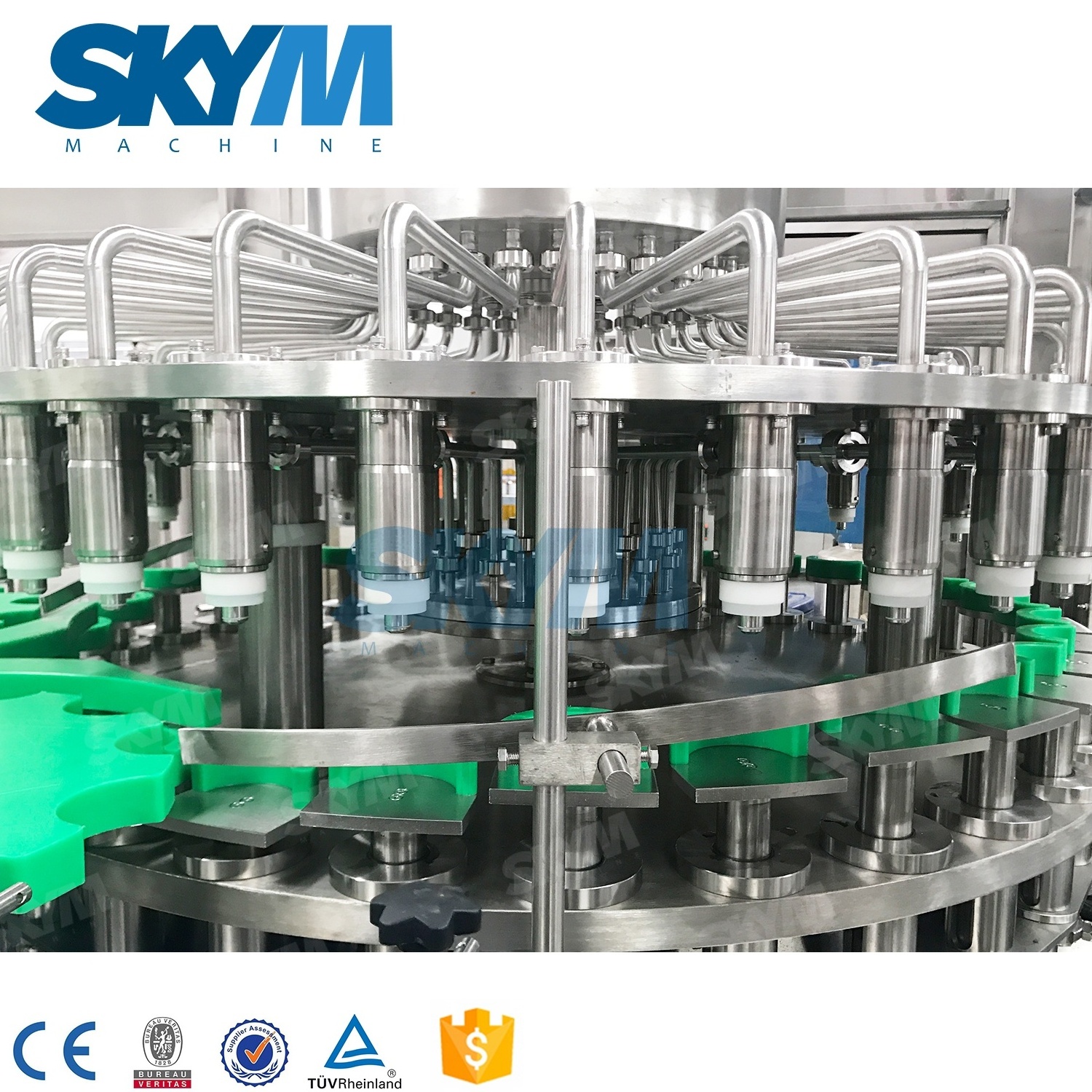

RCGF series drinking water filling machine integrates bottle washing, water filling and capping into one monobloc, and the three processws are carried out full automatically. Itis used in the hot filling of juice and tea beverage. It is equipped with perfect temmperature control system, reverse-flow system, automatic cleaning system and control program. Each machine element that grade rubber.

Rinser

Bottle clip equipped with efficient spray on nozzle.The extrusive droplet with 15 angleensures to wash all side of the bottle.

Filler

The filling valve material is SUS304.The filling system has liquid level automatic control.Filling valve elevator, after filling

valve contact the bottle neck, it starts to fill.

valve contact the bottle neck, it starts to fill.

Capper

The magnetic torque is used for screw capping.The power of screw capping can be adjusted without steps.The power of the screw capping can also be fixed.

Hot Fill Lines

Hot filling technology can expand production and packaging opportunities for juices, nectars, soft drinks, isotonics and teas. No matter your beverage type, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

Hot filling technology can expand production and packaging opportunities for juices, nectars, soft drinks, isotonics and teas. No matter your beverage type, our unmatched expertise helps you achieve more with extensive technical knowledge and packaging capabilities.

With 15 years of hot filling experience, we continue to lead the industry with more than 1,00 proven Skymachine Hot Fill

solutions worldwide. Over the last thirty years, we have significantly reduced the weight of heat-resistant bottles while

retaining their durability and improving design opportunities.

One partner for all your needs.

A complete hot fill line solution from Skymachine Machine lets you optimise performance and make more informed decisions across the lifetime of your line. With everything centred around one supplier, you get wide-ranging expertise, equipment and ongoing services to evaluate your entire project. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and more.

Hot Fill Lines is a unique PET packaging solution offering a great alternative for hot-filled beverages in PET bottles. It expands the opportunities of product premiumisation and revenue generation with no compromise on packaging performance and the consumer experience. This innovative solution is addressing the single serve market of Hot fill (juice, nectar, soft drink, isotonics, tea) filled in PET bottles up to 1.2L at a temperature of 85-88°C.

solutions worldwide. Over the last thirty years, we have significantly reduced the weight of heat-resistant bottles while

retaining their durability and improving design opportunities.

One partner for all your needs.

A complete hot fill line solution from Skymachine Machine lets you optimise performance and make more informed decisions across the lifetime of your line. With everything centred around one supplier, you get wide-ranging expertise, equipment and ongoing services to evaluate your entire project. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and more.

Hot Fill Lines is a unique PET packaging solution offering a great alternative for hot-filled beverages in PET bottles. It expands the opportunities of product premiumisation and revenue generation with no compromise on packaging performance and the consumer experience. This innovative solution is addressing the single serve market of Hot fill (juice, nectar, soft drink, isotonics, tea) filled in PET bottles up to 1.2L at a temperature of 85-88°C.

Technical Characters:

1,Full filling is to avoid bottles from sinking after the bottles cooling off, and to decrease dissolved oxygen to the utmost

extent.

2,Reasonable structured storage hopper an material supply system keep material in the constant flow speed, constant pressure and without frothing. Usually high position tank is adopted.

3,The storage hopper has the characteristic of gas dischanrge, full sealing and temperature detecting, in moderate and high speed production line, the materical distributor replaces the big liquid tank to realize the complete CIP.

4,Sanitary filling head system is of umbrella structure, high filling speed.

5,Prefect filling temperature control system.

6,Return tank system have the function of supplying the material automatically.

7,Perfect CIP system.

extent.

2,Reasonable structured storage hopper an material supply system keep material in the constant flow speed, constant pressure and without frothing. Usually high position tank is adopted.

3,The storage hopper has the characteristic of gas dischanrge, full sealing and temperature detecting, in moderate and high speed production line, the materical distributor replaces the big liquid tank to realize the complete CIP.

4,Sanitary filling head system is of umbrella structure, high filling speed.

5,Prefect filling temperature control system.

6,Return tank system have the function of supplying the material automatically.

7,Perfect CIP system.

Auxiliary Equipments

Real Picture Of Customer Factory

Related Products

Water Treatment System

Automatic PET Bottle Blow Molding machine

Automatic blowing machine adopts our most advanced blowing technologies. This machine is a fully automatic,high intelligent,stable

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

Automatic PVC shrink labeling machine

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components

* Stainless steel Main Machine Frame / Famous electrical components

Automatic PE film shrink wrapping machine

Shrink wrapping machine is suitable for wrapping and packaging of such products as pop-top, mineral water, bottles beer, drinks

etc without bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of

shrink wrapping machine process adopt the Germany advanced technology. It main parts of shrink wrapping machine are imported from

international famous companies, capability stable and using long-time.

etc without bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of

shrink wrapping machine process adopt the Germany advanced technology. It main parts of shrink wrapping machine are imported from

international famous companies, capability stable and using long-time.

Customer Plant Layout

Product Paramenters

|

Model

|

RCGF 14-12-5

|

RCGF 16-16-5

|

RCGF 24-24-8

|

RCGF32-32-10

|

RCGF40-40-12

|

RCGF50-50-15

|

RCGF60-60-15

|

||||||

|

Bottle specifications(mm)

|

200ml To 2000ml

|

|

|

|

|

|

|

||||||

|

Capacity (500ml/bottle/hour)

|

3000-4000

|

5000-7000

|

6000-8000

|

8000-10000

|

12000-15000

|

15000-18000

|

18000-25000

|

||||||

|

Power supply(kw)

|

2.42

|

3.12

|

3.92

|

3.92

|

5.87

|

7.87

|

11.37

|

||||||

|

Overall dimension(L*W*H)MM

|

2360×1770×2700

|

2760×2060×2700

|

2800×2230×2700

|

3550×2650×2700

|

4700×3320×2700

|

5900×4150×2700

|

6700×5160×2700

|

||||||

|

Weight (KG)

|

2600

|

3500

|

4800

|

6500

|

10000

|

12000

|

15000

|

||||||

ABOUT SKYM

Zhangjiagang Sky Machine Co.,Itd is located at Leyu Economic Development Zone of Zhangjiagang City.Our Company was founding

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses aroundthe world to build a professional relationship with us based on trust,benefits and the promising possibility for future development.

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses aroundthe world to build a professional relationship with us based on trust,benefits and the promising possibility for future development.

Hot Searches