- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

1%-2.5%

-

CrO Content (%):

-

-

-

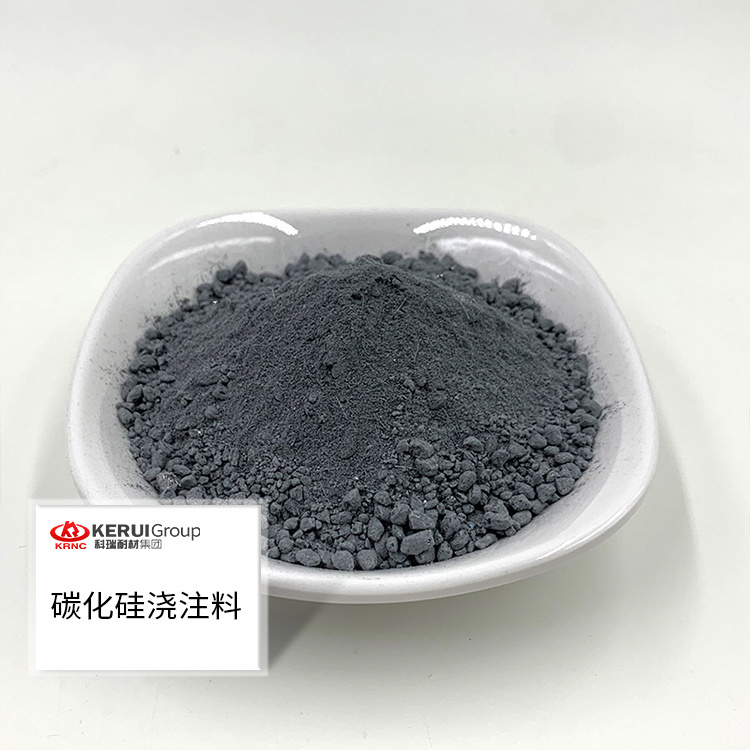

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KERUI

-

Size:

-

Size Customized

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

45%

-

MgO Content (%):

-

-

-

CaO Content (%):

-

1%-2.5%

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KERUI

-

Size:

-

Size Customized

Low Cement Castable:

Low cement castable refers to the new castable with little binding dose. The key is to use ultrafine particles of no more than 1μm. Its thermal shock resistance, slag resistance and erosion resistance are significantly improved, surpassing similar refractory bricks. Further reduction of binder content can produce ultra-low cement castable and cement-free castable.

The cement content of refractory cement castable is generally 15% to 20%, and the cement content of low cement castable is about 5%, and some even reduce to 1% to 2%. The purpose of reducing the amount of cement is to improve the fire resistance of castable.

|

Item/Grade

|

|

|

SICAST 85

|

SICAST 80

|

SICAST 60

|

||

|

Physical Properties

|

Required Quantity (t/m3)

|

|

2.68

|

2.6

|

2.5

|

||

|

|

Water Required for Casting (%)

|

|

45084

|

45084

|

45115

|

||

|

|

CCS (kg/cm2)

|

@ 110℃x24h

|

650(140)

|

500(90)

|

450(70)

|

||

|

|

|

@ 1000℃x3h

|

850(150)

|

600(150)

|

550(100)

|

||

|

|

|

@ 1350℃x3h

|

1100(250)

|

1000(250)

|

1000(250)

|

||

|

|

PLC (%)

|

@ 110℃x24h

|

-0.06

|

-0.06

|

-0.06

|

||

|

|

|

@ 1000℃x3h

|

-0.1

|

-0.1

|

-0.2

|

||

|

|

|

@ 1350℃x3h

|

-0.1

|

-0.1

|

-0.12

|

||

|

|

TC (kcal/mh℃)

|

@ 350℃

|

11.5

|

11

|

8

|

||

|

Chemical Properties

|

ω (Al2O3)/%

|

|

9

|

9

|

20

|

||

|

|

ω (SiC + C)/%

|

|

83

|

78

|

58

|

||

Versatile Application:

Our refractory castable offers remarkable versatility, suitable for various industries and a wide range of applications, including boilers, furnaces, incinerators, and more.

Exceptional Heat Resistance:

Exceptional Heat Resistance:

With an impressive ability to withstand high temperatures, this castable refractory ensures prolonged stability and reliable performance even in the most demanding thermal environments.

Excellent Erosion and Abrasion Resistance:

Excellent Erosion and Abrasion Resistance:

The castable's robust composition enables it to endure aggressive chemical environments, reducing erosion and increasing service life.

Rapid Installation and Setting:

Rapid Installation and Setting:

Easy to install, our refractory castable boasts fast setting times, reducing downtime and improving operational efficiency.

Customizable Consistency:

Customizable Consistency:

Depending on the application, the castable can be tailored to achieve specific densities and strengths, ensuring optimized performance in your unique requirements.

Low Cement Castable

CaO:1%-2.5%

Untra Low Cement Castable

CaO:0.2%-1%

Cementless Castable

CaO:

≤0.2%

1.

It has good peeling property.

2.

It has the ability to resist erosion and erosion.

3.

It has the wear resistance to high temperature environment.

Low Refractory Cement Castable Application:

Boiler Lining:

Boiler Lining:

Our refractory castable provides an efficient lining for industrial boilers, ensuring excellent heat retention and prolonged boiler life.

Furnace Lining:

Furnace Lining:

Ideal for lining various types of furnaces, this castable refractory delivers superior heat resistance and corrosion protection.

Kiln and Incinerator Linings:

Kiln and Incinerator Linings:

From rotary kilns to waste incinerators, this castable offers durable linings capable of withstanding extreme temperatures and chemical exposure.

Foundries:

Foundries:

Used in ladles and troughs, the refractory castable maintains stability under the rigorous conditions of molten metal handling.

Petrochemical Industry:

Petrochemical Industry:

It is a reliable choice for lining cracking units, reformer furnaces, and other high-temperature applications in petrochemical plants.

Power Plants:

Power Plants:

Our castable refractory ensures efficient linings for chimneys, flues, and other components in power generation facilities.

Construction Points:

(1)

When adding water or liquid binder, pay attention to the ratio of refractory castables;

(2) The formwork used for pouring should have sufficient strength, accurate size, and prevent deformation during construction;

(3) The joints of the formwork should be tight and no leakage and anti-sticking measures should be taken before pouring;

(4) Waterproof measures should be taken for the surface of the heat-insulating masonry in contact with the castable;

( 5) The pouring should be carried out continuously. Before the castable of the front layer is set, the pouring of the castable of the second layer should be completed. If the interval exceeds the setting time, it should be treated according to the requirements of the construction joint. Construction joints should stay on the centerline of the same row of anchor bricks;

(6) After the refractory castable is constructed, it should be cured according to the specified method in the design, and it

should not be subjected to external force or vibration during the curing period.

(2) The formwork used for pouring should have sufficient strength, accurate size, and prevent deformation during construction;

(3) The joints of the formwork should be tight and no leakage and anti-sticking measures should be taken before pouring;

(4) Waterproof measures should be taken for the surface of the heat-insulating masonry in contact with the castable;

( 5) The pouring should be carried out continuously. Before the castable of the front layer is set, the pouring of the castable of the second layer should be completed. If the interval exceeds the setting time, it should be treated according to the requirements of the construction joint. Construction joints should stay on the centerline of the same row of anchor bricks;

(6) After the refractory castable is constructed, it should be cured according to the specified method in the design, and it

should not be subjected to external force or vibration during the curing period.

Zhengzhou Kerui Industrial Development Co., Ltd.

Zhengzhou Kerui Industrial Development Co., Ltd. is a branch of Zhengzhou Kerui (Group) Refractory Co., Ltd.. We provide all types of refractory products, including refractory bricks and materials, insulation bricks and materials, kiln shelves and new materials, etc. Kerui Refractory is located in the largest refractory industry zone: Chaohua Town, Xinmi City, Henan Province, China.

Founded in 2004, Kerui Refractory is an international high-tech enterprise integrating R&D and innovation, manufacturing,

solutions and service of high-performance refractory products. Kerui places great importance on R&D. In the past decades, we have obtained one invention patent certificate and more than 20 utility model patent certificates. Kerui insists on technological innovation to provide customers with better products.

Founded in 2004, Kerui Refractory is an international high-tech enterprise integrating R&D and innovation, manufacturing,

solutions and service of high-performance refractory products. Kerui places great importance on R&D. In the past decades, we have obtained one invention patent certificate and more than 20 utility model patent certificates. Kerui insists on technological innovation to provide customers with better products.

Professional R&D Team

Kerui own 50000m² factory ,R&D、production、sales、delivery as one,fully equipped,own patents,support customization.

Professional Sales Team

Kerui has its own sales and service team, proficient in foreign languages, instant communication with customers and can solve customer problems at first time.

Professional Solutions

Kerui has EPC capability, can undertake customer projects, has professional technical experts, according to customer needs to develop the most perfect plan.

Professional After-sale Team

Kerui has its own professional after-sales team, once the customer has any technical problems, it can respond and solve within 1 hour.

Cooperate Partner

Kerui have more than 20 years of technology city store, has supplied Nanshan Copper, Shenhuo Group, Weiqiao aluminum power and other domestic 500 enterprises, quality assurance, honor first.

Kerui Group

Founded in 2004 with a registered capital of 81.8 million Yuan, Zhengzhou Kerui Refractory Material Co. , Ltd. is located in the refractory industry base of Chaohua town, Xinmi Province, After 20 year’s hard work and tenacious struggle , we walked out of a“Product oriented, service first” healthy and rapid development of the road, has developed into a Refractory r & D, production, sales, Product Technology Solutions, Project EPC general contracting services in one of the modern integrated enterprise group.

Testing

- High-temperature reheating/load softening creep test furnace;

- Compressive/flexural strength testing bench for refractory materials;

- Composition testing and inspection platform for refractory materials;

- Laboratory for physical/chemical properties of refractory materials.

- High-temperature reheating/load softening creep test furnace;

- Compressive/flexural strength testing bench for refractory materials;

- Composition testing and inspection platform for refractory materials;

- Laboratory for physical/chemical properties of refractory materials.

Service

- Customized comprehensive solution service;

- Drawing design and materials combination solution;

- Professional construction team;

- Professional after-sales team support and lifetime guarantee;

- Customized comprehensive solution service;

- Drawing design and materials combination solution;

- Professional construction team;

- Professional after-sales team support and lifetime guarantee;

Hot Searches