- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

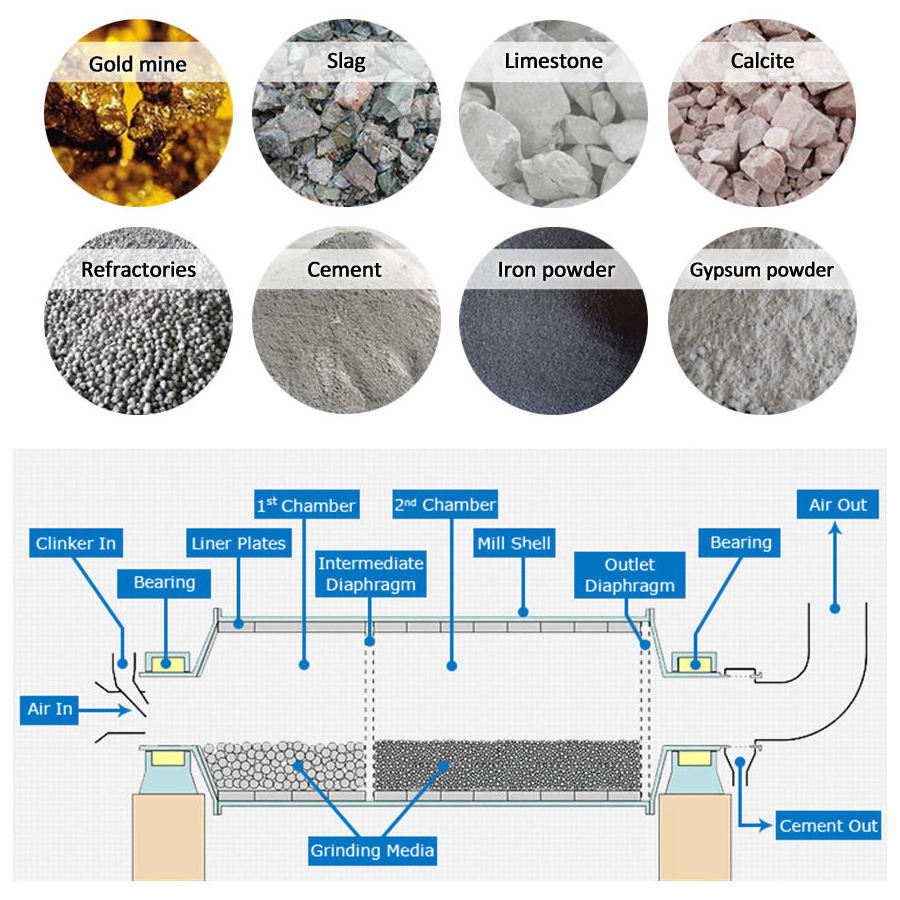

Application:

-

Ore,cement,silicate,new building material,refractory material

-

Price:

-

negotiation

-

Color:

-

As customers' request

-

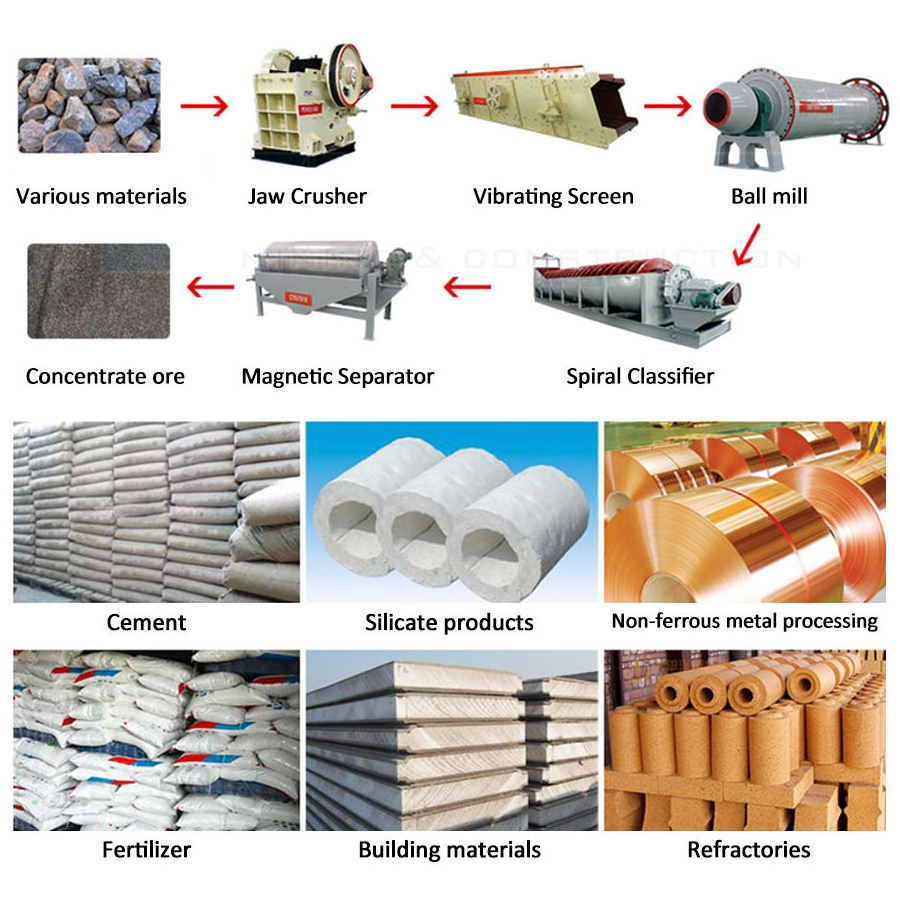

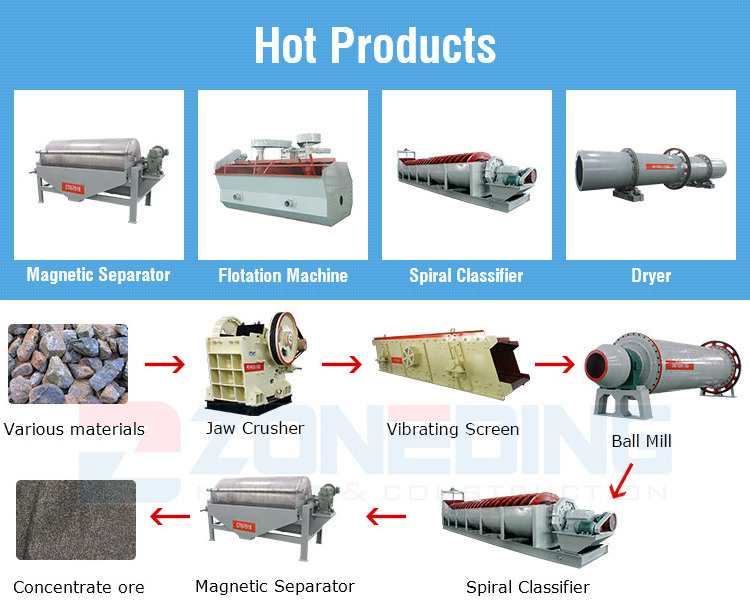

Flowchart:

-

Provide

-

Instalation:

-

Provide

-

Quality:

-

High Reputation

-

Certification:

-

CE,ISO,BV

Quick Details

-

Capacity(t/h):

-

0.5-180t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZONEDING

-

Dimension(L*W*H):

-

According to different models

-

Weight:

-

4000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Ore,cement,silicate,new building material,refractory material

-

Price:

-

negotiation

-

Color:

-

As customers' request

-

Flowchart:

-

Provide

-

Instalation:

-

Provide

-

Quality:

-

High Reputation

-

Certification:

-

CE,ISO,BV

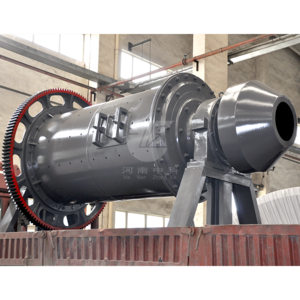

Ball Mill

Zoneding ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

1. When the diameter of the ball mill is less than 3200mm, its conventional configuration is using rolling bearing instead of bush sliding bearing, energy saving 10% - 20%;

2. When the diameter of the ball mill is more than 2700mm, its conventional configuration is using slow driving device for installing liner and maintenance;

3. When the diameter of the ball mill is less than 1500mm, its conventional configuration is monolithic large chassis, then reduce installation requirements and shorten installation time.

| Model | Speed (r/min) | Max. weight of balls (t) | Input size (mm) | Output size (mm) | Power (kw) | Capacity (t/h) | Weight (t) |

| Φ900×1800 | 37 | 1.8 | ≤15 | 0.075-0.89 | 15 | 0.5-2 | 3.4 |

| Φ900×2100 | 37 | 2.3 | ≤15 | 0.075-0.4 | 18.5 | 0.4-2 | 3.9 |

| Φ900×3000 | 35 | 3.85 | ≤25 | 0.075-0.4 | 30 | 1.1-2.5 | 7.78 |

| Φ1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.4 | 30 | 1.3-3.2 | 8.65 |

| Φ1200×2800 | 35 | 5.4 | ≤25 | 0.075-0.4 | 37 | 1.5-3.7 | 10.02 |

| Φ1200×4500 | 35 | 8.6 | ≤25 | 0.075-0.4 | 45 | 2.7-6.79 | 14 |

| Φ1500×3000 | 29 | 9 | ≤25 | 0.047-0.4 | 75 | 3.3-8.2 | 14.12 |

| Φ1500×3500 | 29 | 10.5 | ≤25 | 0.047-0.4 | 75 | 3.3-8.5 | 15.64 |

| Φ1500×4500 | 29 | 13.5 | ≤25 | 0.047-0.4 | 90 | 4.5-12 | 20 |

| Φ1500×5700 | 29 | 17 | ≤25 | 0.047-0.4 | 110 | 2.6-14 | 21.5 |

| Φ1830×3000 | 24 | 13.5 | ≤25 | 0.047-0.4 | 135 | 4-15 | 28 |

| Φ1830×3600 | 24 | 14 | ≤25 | 0.047-0.4 | 135 | 4-15 | 29 |

| Φ1830×4500 | 24 | 20 | ≤25 | 0.047-0.4 | 155 | 4-19 | 32 |

| Φ1830×7000 | 24 | 31.5 | ≤25 | 0.047-0.4 | 210 | 6-22 | 37.5 |

| Φ2100×3000 | 22 | 18 | ≤25 | 0.047-0.4 | 210 | 6.4-28 | 40.79 |

| Φ2100×3600 | 22 | 20 | ≤25 | 0.047-0.4 | 210 | 7-28 | 42 |

| Φ2100×4000 | 22 | 21.5 | ≤25 | 0.047-0.4 | 210 | 7.6-28 | 43.45 |

| Φ2200×3600 | 21.7 | 25 | ≤25 | 0.047-0.4 | 245 | 5.2-32 | 44 |

| Φ2200×7000 | 21.7 | 46 | ≤25 | 0.047-0.4 | 380 | 15-38 | 63 |

| Φ2400×3600 | 21 | 28 | ≤25 | 0.047-0.4 | 320 | 8-60 | 47 |

| Φ2400×4500 | 21 | 35 | ≤25 | 0.047-0.4 | 380 | 8.5-60 | 70.5 |

| Φ2700×3600 | 20.7 | 40 | ≤25 | 0.047-0.4 | 400 | 12-80 | 75.5 |

| Φ2700×4500 | 20.7 | 48 | ≤25 | 0.047-0.4 | 450 | 12-90 | 102 |

| Φ3200×4000 | 18 | 65 | ≤25 | 0.047-0.4 | 800 | 30-180 | 137 |

Note: Any change of technical data shall not be advised additionally.

FAQ:

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q: Do you provide beneficiation flow chart?

A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.