- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Dimension(L*W*H):

-

170*82*169cm

-

Weight:

-

280 KG

-

Number of card slots:

-

8

-

Tail sealing process:

-

ultrasonic

-

Machine functions:

-

Integrated filling and sealing of hoses

-

feeding tube system:

-

Inclined hanging automatic row feeding tube bin

-

Filling nozzle:

-

Air blowing and shredding function

-

Suitable for hose height range:

-

5-200mm

-

Applicable raw materials::

-

Plastic composite pipe; aluminum-plastic composite pipe

-

Operation method:

-

PLC Screen

-

Running speed:

-

60rpm/min

-

Suitable hose diameter:

-

10-50mm

Quick Details

-

Machinery Capacity:

-

adjustable

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Milk, Water, Oil, Juice, Other

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Gondor

-

Dimension(L*W*H):

-

170*82*169cm

-

Weight:

-

280 KG

-

Number of card slots:

-

8

-

Tail sealing process:

-

ultrasonic

-

Machine functions:

-

Integrated filling and sealing of hoses

-

feeding tube system:

-

Inclined hanging automatic row feeding tube bin

-

Filling nozzle:

-

Air blowing and shredding function

-

Suitable for hose height range:

-

5-200mm

-

Applicable raw materials::

-

Plastic composite pipe; aluminum-plastic composite pipe

-

Operation method:

-

PLC Screen

-

Running speed:

-

60rpm/min

-

Suitable hose diameter:

-

10-50mm

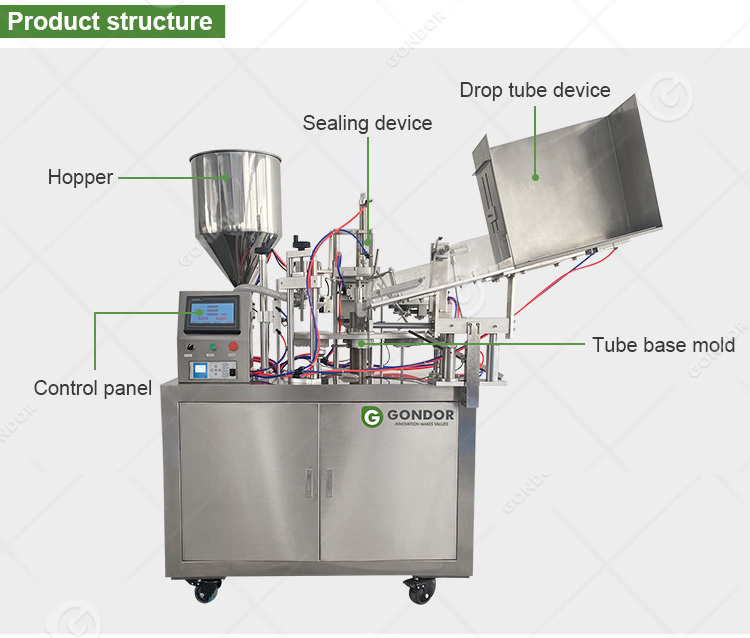

Introduction

The fully automatic hose filling and sealing machine is a high-tech product successfully developed and designed using advanced foreign technology and in strict accordance with GMP requirements. This machine can automatically complete the filling, sealing or tail folding of ointments, creams, jelly or sticky materials, and batch number stamping (including production date). Its surface is smooth, flat, non-toxic, odorless, pollution-free, no dead ends, and easy to clean and maintain. The machine has a compact structure, simple structure and easy operation, and is suitable for the needs of users in the pharmaceutical, food, daily chemical products and other industries. It is ideal for filling and sealing hoses in the cosmetic, food and adhesive industries.

Application

Automatic Tube filling and sealing machine is mainly used for filling and sealing composite tube,with unique design concept.The whole sealing process goes smoothly and print beautifully.

Automatic Tube filling and sealing machine uses ultrasonic sealing, which has low cost, good effect, high production efficiency and high degree of automation. It is suitable for beauty shops, catering companies, daily chemical products industry, Paste production industry, etc.

Features

1. This machine adopts microcomputer chip and intelligent control.

2 . Automatic counting function, filling speed measurement can be set.

3 . Turntable structure, multiple stations can work at the same time, and the work efficiency is high.

4 . Use high-quality color mark sensors to resist interference, and the marking accuracy is as high as 99.99%.

5 . Ultrasonic tail sealing, sharp slices, made of aluminum alloy.

Parameter

| Model | GD-ATFS-60 |

| Voltage | 220v 50hz |

| Running speed | 60rpm/min |

| Filling capacity | 5-250ml |

| Filling accuracy | ≤±1% |

| Suitable for hose length | 50-240mm |

| Suitable for hose diameter | 10-50mm |

| Maximum processing height | 5-200mm |

| Feeding system | Inclined hanging automatic row feeding tube bin |

| Size | 170×82×169cm |

| Weight | 280kg |

Q1. What should I do if we are not able to operate the machine when we receive it?

Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer's site to solve any problems.

Q2. What is the maximum height that this fully automatic filling and sealing machine can operate?

The maximum height our machine can do is 200mm.

Q3. What is the sealing process of this machine?

Our machine uses ultrasonic sealing technology, the slices are sharp, accurate and fast.

Q4. Can this machine achieve precise filling?

Our machine uses high-quality color mark sensors for anti-interference/sensitive and non-contact marking, with an accuracy of up to 99.99%.

Q5. What is the output of this machine?

The output needs to be analyzed based on the height and diameter of the hose you want to fill. You can send us a private message in the background.

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.