- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 220v

-

Power:

-

110kw

-

Weight:

-

3800 KG

-

Dimension(L*W*H):

-

15000*1200*2500mm

-

Product name:

-

Aqua Feed Pellet making equipment

-

Capacity:

-

1 - 3 T/h

-

Type:

-

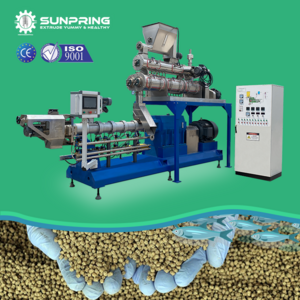

Double Screw Extruder Machine

-

Function:

-

Producing Animal Feeds Pellets

-

Motor:

-

Chinese Brand

-

Machine material:

-

Stailess Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Raw material:

-

corn,fish meal,shrimp meal

-

After-sales Service:

-

Service Machinery Overseas

-

Certification:

-

CE ISO

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HALO

-

Voltage:

-

380V, 220v

-

Power:

-

110kw

-

Weight:

-

3800 KG

-

Dimension(L*W*H):

-

15000*1200*2500mm

-

Product name:

-

Aqua Feed Pellet making equipment

-

Capacity:

-

1 - 3 T/h

-

Type:

-

Double Screw Extruder Machine

-

Function:

-

Producing Animal Feeds Pellets

-

Motor:

-

Chinese Brand

-

Machine material:

-

Stailess Steel

-

Advantage:

-

Easy Operation High Efficiency

-

Raw material:

-

corn,fish meal,shrimp meal

-

After-sales Service:

-

Service Machinery Overseas

-

Certification:

-

CE ISO

Product Description

The fish feed making machine line

With new technology of combination screws, our twin screw extruder production line is applied to produce different fish feed with various material and nutritional elements, the production parameters are precisely controlled. Through extruding, the degraded protein is easy to be absorbed.

Ingredients to use :

With new technology of combination screws, our twin screw extruder production line is applied to produce different fish feed with various material and nutritional elements, the production parameters are precisely controlled. Through extruding, the degraded protein is easy to be absorbed.

It can produce various

Aqua feed

such as

Shrimp feed

, fish feed, and other aquatic feed.

Ingredients to use :

corn meal, fish meal,shrimp meal, addtives, etc.

Machines need:

1. Mixer to mix the ingredients .

2. screw conveyor to transfer the mixed ingredients to the extruder.

3. Extruder to produce the feed under high temperature and high pressure.

4. Air conveyor to transfer the fish feed to oven.

5. Oven : to reduce the moisture from the fish feed.

6. Flavoring machine to coat the animal fat to fish feed.

7. Packing machine to pack the fish feed to packages.

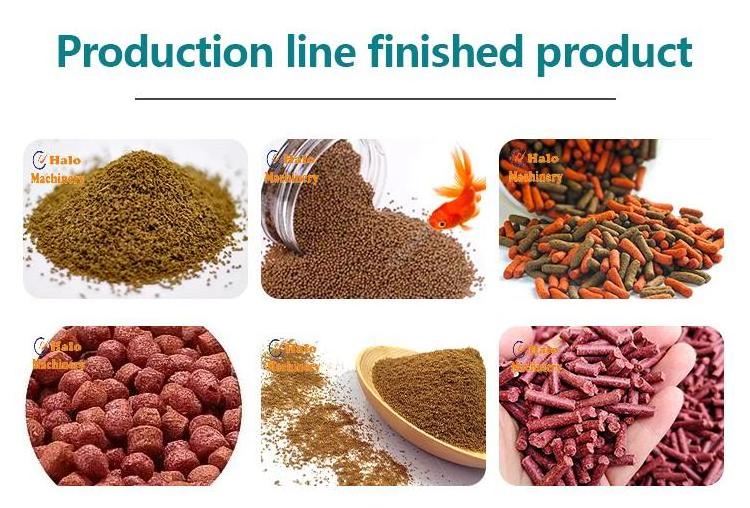

Shapes to produce:

Machines need:

1. Mixer to mix the ingredients .

2. screw conveyor to transfer the mixed ingredients to the extruder.

3. Extruder to produce the feed under high temperature and high pressure.

4. Air conveyor to transfer the fish feed to oven.

5. Oven : to reduce the moisture from the fish feed.

6. Flavoring machine to coat the animal fat to fish feed.

7. Packing machine to pack the fish feed to packages.

Shapes to produce:

Change different mould, can produce different size and shapes.

Capacity:

Capacity:

50-80kg/h, 120-150kg/h, 200-250kg/h, 400-500kg/h , 800-100kg/h , 1.5-1.8tons/h, 3-4tons/h. etc

Product Display

|

Machine Name

|

Mixer

|

|

Power

|

5.5/7.5/11kw

|

|

Capacity

|

70-100kg/batch

|

|

Materials

|

Stainless steel

|

|

Function

|

It makes the powder raw materials, water and additives stirred and mix evenly by the high-speed rotation stirring wings in the stirring drum. Drum and stirring wings are made of stainless steel.

|

|

Suitable

|

COrn powder, wheat flour, starch etc

|

|

Machine name

|

Screw conveyor

|

|

Power

|

1.1kw/2.2kw

|

|

Diameter of the tube

|

131mm

|

|

Length

|

3meters , 4meters , .The support can be adjusted to match other machines' height.

|

|

Materials

|

Stanless steel

|

|

Function

|

Transfer the mixed ingredients to the extruder

|

|

Machine name

|

steam preconditoner

|

|

Power

|

5.5/7.5/11/15kw

|

|

Materials

|

Stainless steel

|

|

Function

|

to precook the ingredients via steam filling

|

|

Machine name

|

HL100 Twin screw extruder

|

HL75 Twin screw extruder

|

|

|

Main motor power

|

110/132kw

|

55/75kw

|

|

|

Screw materials

|

Cr12MoV

|

|

|

|

Barrel materials

|

45# steel, with alloy steel inserted for long time use

|

45# steel, with alloy steel inserted for long time use.

|

|

|

Capacity

|

1500-2000kg/h

|

250-400kg/h

|

|

|

Product

|

puffs, snack pellet, soya protein, dog food, fish feed, fried snacks, modified starch, baby food etc.

Pedigree dog food making machine made in china with dryer

|

|

|

|

Machine name

|

Air conveyor

|

|

Power

|

0.37/0.75/1.1/2.2/3kw

|

|

Materials

|

All stainless steel

|

|

Parts

|

Hopper, motor, tube, cyclone

|

|

Function

|

Transfer the food to the oven/

dryer Grinding kibble pet food dog pellet project making machine

edigre dog food making machine made in china with dryer

|

|

Machine name

|

Dryer /Oven

|

|

Driving power

|

0.75/1.1/2.2/5.5kw

|

|

Heating energy

|

Electricity, gas, diesel oil.

|

|

Layers

|

3 layers, 5 layers, 7 layers

|

|

Length

|

3meters, 5meters, 7meters, 9meters

|

|

Materials

|

Stainless steel belt.

Grinding kibble pet food dog pellet project making machine

|

|

Machine name

|

Seasoning machine

|

|

Parts

|

Hoister, flavor feeder, double drums, oil sprayer

|

|

Materials

|

stainless steel

|

|

Drum size

|

Dia650mm, Dia 800mm

|

|

Drum length

|

1500, 1900mm

Grinding kibble pet food dog pellet project making machine

|

Hot Searches