- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9

-

Voltage:

-

made to client's order

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JST

-

Dimension(L*W*H):

-

2650x2100x2150 mm

-

Weight:

-

2500 KG

-

Bottle:

-

Glass bottle or PET bottle

-

Size:

-

250ml-1500ml

-

Cap:

-

crown cap or aluminum long cap

-

Control:

-

PLC & touch screen

-

PLC brand:

-

Siemens

-

Label:

-

paper label or self-adhesive label

-

Process:

-

glass bottle wine making machinery

Quick Details

-

Machinery Capacity:

-

3000BPH

-

Packaging Material:

-

Plastic, Metal, Glass, glass bottle wine making machinery

-

Filling Material:

-

red wine, alcohol drink, whisky, vodka

-

Filling Accuracy:

-

99.9

-

Voltage:

-

made to client's order

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JST

-

Dimension(L*W*H):

-

2650x2100x2150 mm

-

Weight:

-

2500 KG

-

Bottle:

-

Glass bottle or PET bottle

-

Size:

-

250ml-1500ml

-

Cap:

-

crown cap or aluminum long cap

-

Control:

-

PLC & touch screen

-

PLC brand:

-

Siemens

-

Label:

-

paper label or self-adhesive label

-

Process:

-

glass bottle wine making machinery

Product Overview

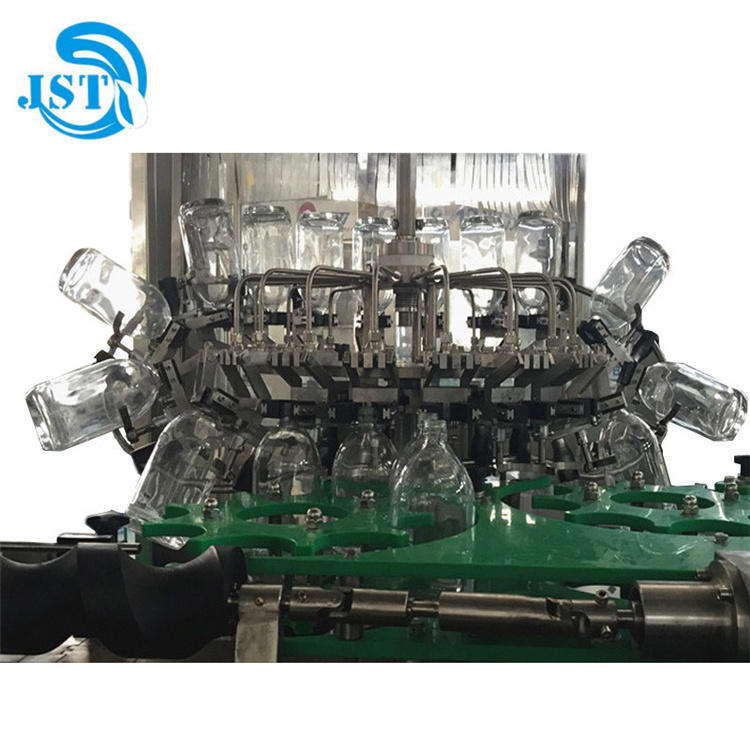

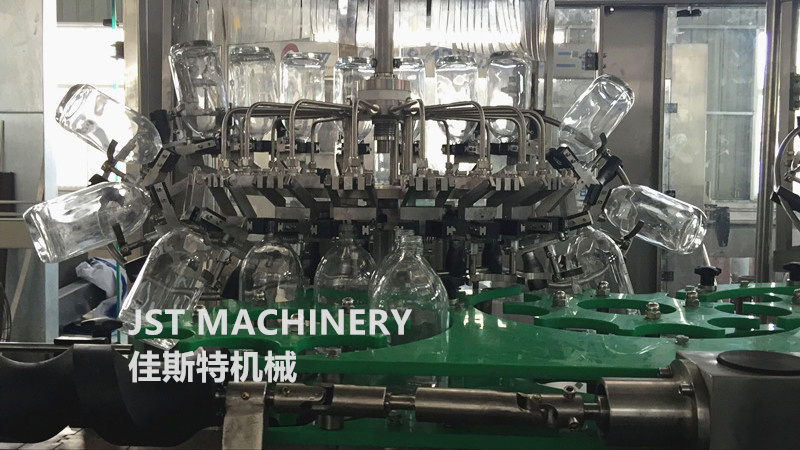

Full automatic glass bottle wine filling making machinery

This BGF Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce alcoholic beverage (whisky ,red wine ,vodka ) machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.Machine price from Zhangjiagang jst machinery is also economic .

FEATURES AT A GLANCE

1. Model BGF32-32-8

2.Capacity : 8000BPH (500ml)

3. Suitable : Plastic bottle 250ml-2000ml

4. Machine size : 3050x2650x2250mm

5.Machine electric brand : SIEMENS , MITSUBISHI

6.Machine power : 7.5KW

7. Machine weight : 4500kg

8. Machine include function :washing filling capping ,cap elevator

9. Application: Beverage wine , such as whisky ,vodka ,red wine ,white wine and so on .

3. Suitable : Plastic bottle 250ml-2000ml

4. Machine size : 3050x2650x2250mm

5.Machine electric brand : SIEMENS , MITSUBISHI

6.Machine power : 7.5KW

7. Machine weight : 4500kg

8. Machine include function :washing filling capping ,cap elevator

9. Application: Beverage wine , such as whisky ,vodka ,red wine ,white wine and so on .

This is three in one machine ,we also have small filling capacity for linear type wine filling line

This is rinsing part of the three in one machine

Function : washing bottle inside and outside ,remove the dust .

1. All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2.All 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3.All 304/316 stainless steel washing pump

Wine filling nozzles of 3 in 1

Fucntion : filling wine into bottle .

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in

fine rank, same liquid level after filling

fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping head of 3 in 1 machine

Function : put caps on bottle ,then seal the caps .

<1> Place and capping system,

electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction <3> No bottle no capping

<4> Automatic stop when lack of bottle

<5> Usually we will make cap elevator for you .please check the following elevator photos

The above photos ,they are for cap elevator

It has cap cover when load the caps to the filling machine .

Air Conveyor

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

-Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316. - Rack made by high quality carbon steel welded.

Flat sending conveyor belt :

Usually for glass bottles, we will make stainless steel 304 type for you ,for plastic bottles ,we will make plastic sending conveyor belt for you .

- Energy saving. High efficient. Adapt to customer factory layout - Special lubrication system, keep products clean, health,

safety

safety

- Extended service life

- Electric eyes design keep whole line running safety and quickly

- Electric eyes design keep whole line running safety and quickly

- Overload protection mechanism to effectively ensure the safety of the machine

Pre-sales service &After sales service

Pre-sale Service:

1.We welcome you to visit us, and we can go to pick you up at shanghai pudong international airport by car.

2.We have professional English sales persons who can make the complete quotation for you, and can guide you how to choose the machines, (such as how to choose labeling machine, how to choose packing machine, how to choose blowing machine, how to design PVC

labels, how to calculate PE packaging films, how to arrange your workshop layout and so on).

After-sales Service, if corona is not serious in your country :

1.We will send operation book, electricity drawing by email to you .

2.For all of our machines, the warranty time is: 24 months since delivery.

3.Once machine arrives to your country, we will guide you to prepare the electricity, welding machine, and raw material. At the same time, we will begin to make the visa for our engineers.

4.Usually for complete filling line, it will take engineer 15 -20days at least to install in your country . For single machine,

usually it will take him 7-10 days to install in your city. Please check the following installation photos by our engineer:

If corona is serious in your country :

1). We will support online -teaching for filling line installation .

2). We will check whether we have engineer near your city or near your country ,if yes ,we will ask them to install the filling

line for you ,but usually the salary will be a little expensive .

1.We welcome you to visit us, and we can go to pick you up at shanghai pudong international airport by car.

2.We have professional English sales persons who can make the complete quotation for you, and can guide you how to choose the machines, (such as how to choose labeling machine, how to choose packing machine, how to choose blowing machine, how to design PVC

labels, how to calculate PE packaging films, how to arrange your workshop layout and so on).

After-sales Service, if corona is not serious in your country :

1.We will send operation book, electricity drawing by email to you .

2.For all of our machines, the warranty time is: 24 months since delivery.

3.Once machine arrives to your country, we will guide you to prepare the electricity, welding machine, and raw material. At the same time, we will begin to make the visa for our engineers.

4.Usually for complete filling line, it will take engineer 15 -20days at least to install in your country . For single machine,

usually it will take him 7-10 days to install in your city. Please check the following installation photos by our engineer:

If corona is serious in your country :

1). We will support online -teaching for filling line installation .

2). We will check whether we have engineer near your city or near your country ,if yes ,we will ask them to install the filling

line for you ,but usually the salary will be a little expensive .

Exhibition

Customer Photos

Hot Searches