- Product Details

- {{item.text}}

Quick Details

-

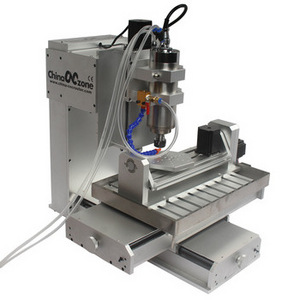

Travel (X Axis)(mm):

-

300 mm

-

Travel (Y Axis)(mm):

-

400 mm

-

Repeatability (X/Y/Z) (mm):

-

0.05 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UTECH

-

Voltage:

-

110V/220V

-

Dimension(L*W*H):

-

61.5*48.5*38.5mm

-

Weight (KG):

-

19

-

Control system:

-

Mach3 controller

-

Frame material:

-

6061-T5 aluminium alloy

-

Max working area:

-

XYZ=290*380*60MM

-

Stepper driver:

-

Independent drive of each axis.High performance

-

Track type:

-

Chrome-plated liner bearing

-

XYZ motor:

-

Stepper motor JK57HS41-2004

-

Transmission:

-

T-screw,diameter of 12mm

-

Feed rate:

-

1500mm/min

-

location accuracy:

-

0.05mm

-

Holder:

-

ER11(3.175mm,6mm)

Quick Details

-

Working Table Size(mm):

-

300×400

-

Machine Type:

-

CNC Router

-

Positioning Accuracy (mm):

-

0.05 mm

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Y Axis)(mm):

-

400 mm

-

Repeatability (X/Y/Z) (mm):

-

0.05 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UTECH

-

Voltage:

-

110V/220V

-

Dimension(L*W*H):

-

61.5*48.5*38.5mm

-

Weight (KG):

-

19

-

Control system:

-

Mach3 controller

-

Frame material:

-

6061-T5 aluminium alloy

-

Max working area:

-

XYZ=290*380*60MM

-

Stepper driver:

-

Independent drive of each axis.High performance

-

Track type:

-

Chrome-plated liner bearing

-

XYZ motor:

-

Stepper motor JK57HS41-2004

-

Transmission:

-

T-screw,diameter of 12mm

-

Feed rate:

-

1500mm/min

-

location accuracy:

-

0.05mm

-

Holder:

-

ER11(3.175mm,6mm)

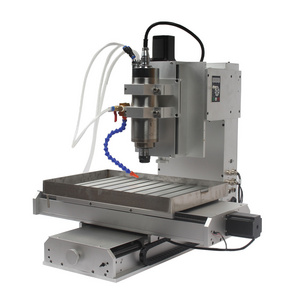

High precision 1500W 3040 router CNC 3 axis CNC milling machine for Copper

|

Type |

3040 |

|

Max working travel |

XYZ=290*380*60mm |

|

Machinable material thickness |

≤70mm |

|

Dimensions |

525*400*290mm |

|

Frame material |

6061-T5 aluminium alloy |

|

Track type |

Chrome-plated + linear bearing |

|

Spiral type |

T-screw, diameter of 12mm, Thread pitch 2mm |

|

Ball screw, diameter of 12mm, Thread pitch 4mm |

|

|

Mechanical resolution |

XYZ axis:0.0025mm/step |

|

PositionaI accuracy |

0.05mm |

|

Spindle motor |

2-300W DC spindle |

|

Revolving speed |

11000rpm/min |

|

Holder |

ER11(3.175mm,6mm) |

|

XYZ motor |

Stepper motor JK57HS41-2004XB-01AF |

|

Stepper driver |

High performance, independent of each axis |

|

Feed rate |

1500mm/min |

|

Communication Interface |

USB2.0 |

|

System requirement |

WIN-XP or WIN-7 |

|

Instruction code |

G code/.nc/.ncc/ .tab/.txt |

|

Voltage |

Input 85V-240VAC(400HZ) |

|

Operating environment |

Temperature: 5 ℃ -40 ℃ ; Humidity: 35%-80 % |

|

Packaging size |

25.5kg(61.5*48.5*38.5 mm) |

The CNC router is suitble for Industry, Technology Research, Advertising Design, Arts Creation, Teaching, Student Project and Hobby Purposes.

The cnc router is designed for large area engraving work such as Industrial or Hobby Prototype Building, Building Model Making, PCB, Advertising Signs, Artwork, Crafts, Aircraft Models, RC Model parts, etc. So, you can do engraving work at office or home.

In addition, it can be upgraded to be installed a rotational axis.

More Precise Stepping Motor

The engraving process is visible as controlled by computer

Simple operation and installation

1 year machine part and 6 months electrical parts , stepping motor , spindle Free Warranty

Packing list:

1× CNC 3040 Engravine machine

1× Control box

1× Parallel port cable 25pin

1× Power cable

1× Tool box and tools

3× Axis motors

1× Rotation axis(optional)

1× tool auto-checking instrument

1× CD of manual and software MACH3 (if not get, may be lost in customs, please contact us).

How to use:

Please see the English user manual to see how to set up the software and how to use this machine.

1. Assembling and locating the CNC machine on steady desk well.

2. Make sure that your computer has a on-board parallel port output.

3. Installing a CNC control software and Drive such as the MACH 3 or EMC2 on your computer.

4. Connecting the control box with the CNC machine and you computer.

5. Fllowing our manual or guideline to set uo the software.

6. You can enjoy making you dream with using our CNC machine now.