- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Foam-010FR

-

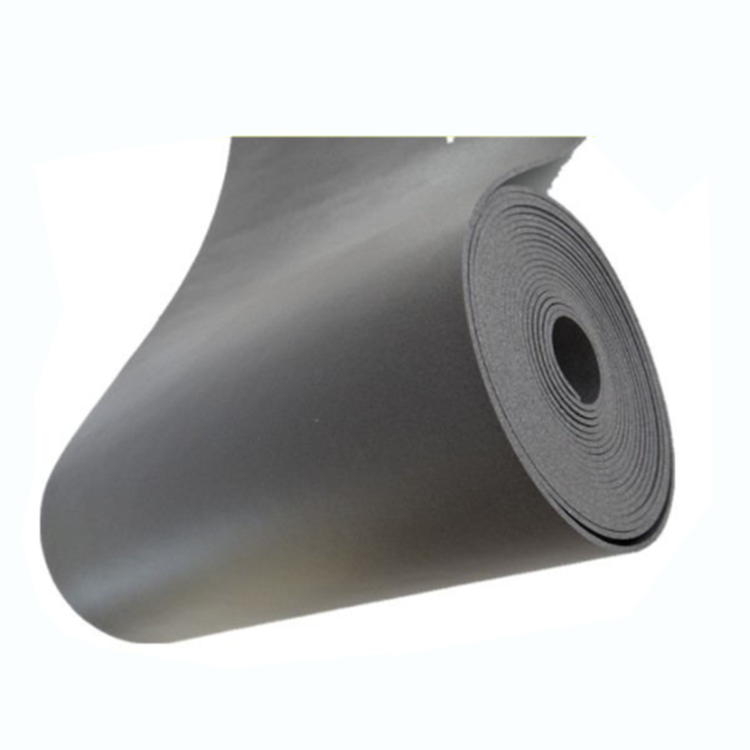

Thickness:

-

3-10mm

-

Size:

-

60-150 cm width

-

Density:

-

28-300kg/cbm

-

Foam Structure:

-

Close cell

-

Features:

-

waterproof ,high cusion ability , durable chemical resistance

-

features:

-

Bacteria & gem resistant

-

pPocessing offered:

-

cut to size ,die cut ,CNC milling embossing ,heat pressing

-

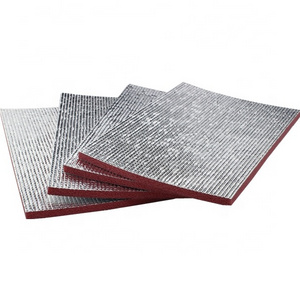

Thickness solution:

-

laminate to thick foam ,split to thin foam

-

heat Shrinking rate:

-

less then 5%

-

Applicaton:

-

packing

-

Max Thickness:

-

can be laminated to 300mm

-

Temperature:

-

-60-100 ℃

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hanata

-

Model Number:

-

Foam-010FR

-

Thickness:

-

3-10mm

-

Size:

-

60-150 cm width

-

Density:

-

28-300kg/cbm

-

Foam Structure:

-

Close cell

-

Features:

-

waterproof ,high cusion ability , durable chemical resistance

-

features:

-

Bacteria & gem resistant

-

pPocessing offered:

-

cut to size ,die cut ,CNC milling embossing ,heat pressing

-

Thickness solution:

-

laminate to thick foam ,split to thin foam

-

heat Shrinking rate:

-

less then 5%

-

Applicaton:

-

packing

-

Max Thickness:

-

can be laminated to 300mm

-

Temperature:

-

-60-100 ℃

|

item

|

value

|

|

Place of Origin

|

China

|

|

Density

|

30~300kg/m

3

|

|

Material

|

XPE

|

|

Foam Expansion ratio

|

2~35

|

|

Width

|

60~150mm

|

|

Thickness

|

3~12mm for single layer

|

|

Testing Item

|

Properties

|

|

|

|

|

|

|

|

|||||||

|

|

5 times

|

8 times

|

10 times

|

15 times

|

20 times

|

25 times

|

30 times

|

35times

|

|||||||

|

Density

kg/m

3

|

200±30

|

125±15

|

100±10

|

66.7±8

|

50±6

|

40±4

|

33.3±3

|

28.6±2

|

|||||||

|

Shore Hardness°

|

60~70

|

50~60

|

45~50

|

35~45

|

30~35

|

25~30

|

18~25

|

13~18

|

|||||||

|

Water Absortion Rate (23℃ ±24h)g/cm

2

|

≤0.02

|

≤0.02

|

≤0.03

|

≤0.03

|

≤0.04

|

≤0.04

|

≤0.05

|

≤0.05

|

|||||||

|

Thermal conductivity

(W/m.k)

|

≤0.092

|

≤0.082

|

≤0.072

|

≤0.062

|

≤0.053

|

≤0.047

|

≤0.041

|

≤0.038

|

|||||||

|

Tensile Strength

(L/W)MPa

|

≥1.35/1.08

|

≥1.12/0.89

|

≥0.88/0.71

|

≥0.68/0.56

|

≥0.39/0.33

|

≥0.33/0.25

|

≥0.25/0.2

|

≥0.2/0.16

|

|||||||

|

Tensibility(L/W)%

|

≥260/220

|

≥230/220

|

≥210/185

|

≥190/170

|

≥170/150

|

≥160/135

|

≥140/130

|

≥120/110

|

|||||||

|

tearing strength(L/W)kN/m

|

≥5.9/7.1

|

≥4.8/5.4

|

≥3.6/4.0

|

≥2.8/3.3

|

≥1.8/2.3

|

≥1.6/2.0

|

≥1.35/1.7

|

≥1.25/1.5

|

|||||||

|

compression set(25%,22h)%

|

≤5

|

≤6

|

≤7

|

≤7

|

≤9

|

≤9

|

≤11

|

≤11

|

|||||||

|

Dimensional Change rate

(70±,22h)(L/W)%

|

≤-6/-4

|

≤-6/-4

|

≤-6/-4

|

≤-6/-4

|

≤-6/-4

|

≤-6/-4

|

|

|

|||||||

Our Advantages

We have many sleeping bags in stock,if you need other size,please contact with us.

1.Good knowledge on different market can meet special requirements.

2.Strong professional technical team ensure to produce the top quality products.

3.Special cost control system ensure to provide the most favorable price.

4.Rich experience om outdoor equipment.

1.Good knowledge on different market can meet special requirements.

2.Strong professional technical team ensure to produce the top quality products.

3.Special cost control system ensure to provide the most favorable price.

4.Rich experience om outdoor equipment.

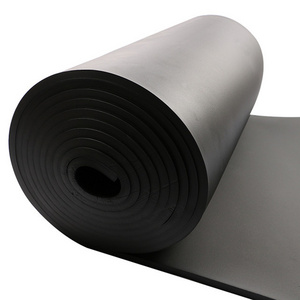

The company currently has two production lines,the main equipment are granulators ,mixers,extruding machines and level of foaming furnace,otherwise are laminating machines,slicing machines,corona machines,embossing machines,cutting machines and other equipment to provide back-end products processing and production.

In addition,be in China at present ,HANATA is still one of the most professional companies which specializes in XPE/IXPE

cross-linked polyethylene foam production line's design,production,innovation,etc.;And it analyzes the relevant mechanical

principles and production processes.It is also do a lot of work in related technology research and development,raw material formula modification,new product development,product application and market development.

In addition,be in China at present ,HANATA is still one of the most professional companies which specializes in XPE/IXPE

cross-linked polyethylene foam production line's design,production,innovation,etc.;And it analyzes the relevant mechanical

principles and production processes.It is also do a lot of work in related technology research and development,raw material formula modification,new product development,product application and market development.

Our Service

We have our own factory,specialized in outdoor production for many years.

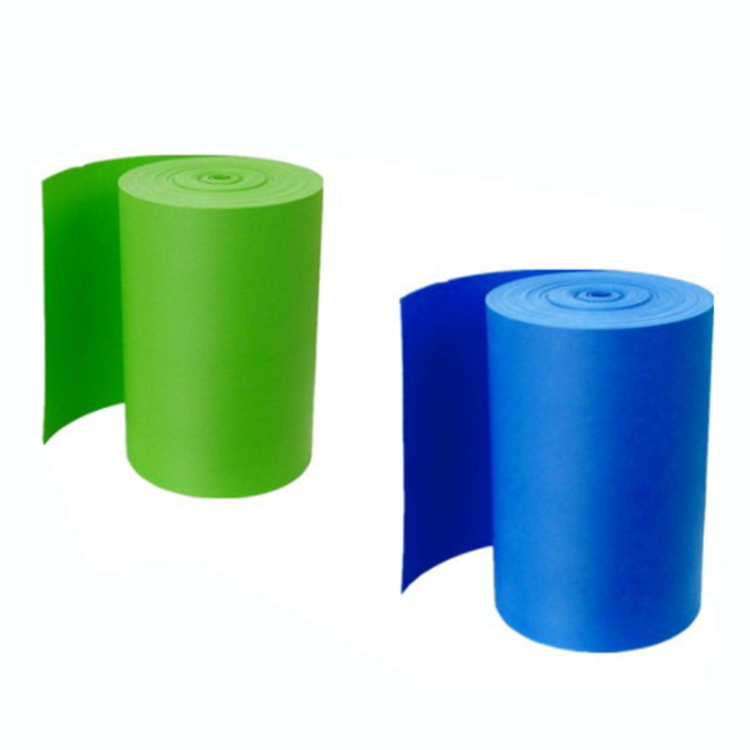

1.Material Customized 2.Logo Customized

3.Color Customized 4.Size Customized

1.Material Customized 2.Logo Customized

3.Color Customized 4.Size Customized

How to order?

1)Tell us the model and the quantities yo want to order.

2)We will make PI for you

3)Checking PI and confirm it for us,we will arrange the production ASAP when payment received.

4)We will take photos for you to confirm and deliver the goods soon.

5)Send the track number for you and track the goods for you until you get it.Sampling date it will take around 7 days.

6)Mass production delivery it as 15-45days.Depends on quantity.

2)We will make PI for you

3)Checking PI and confirm it for us,we will arrange the production ASAP when payment received.

4)We will take photos for you to confirm and deliver the goods soon.

5)Send the track number for you and track the goods for you until you get it.Sampling date it will take around 7 days.

6)Mass production delivery it as 15-45days.Depends on quantity.

How does your quality control?

We have a professional QC team,we will control the goods quality during all the mass production,and we can do inspection service for you.We will try our best to help clients when problem occurred.

How to pay?

1)Western Union /T/T(Telegraphic transfer)/L/C all acceptable

2)30%deposit and 70% before shipping all goods out is acceptable.

We have our own factory,specialized in outdoor production for ,many years.

2)30%deposit and 70% before shipping all goods out is acceptable.

We have our own factory,specialized in outdoor production for ,many years.

Hot Searches