- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

900*670*860

-

Weight:

-

600 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

Quick Details

-

Application:

-

sand making plant

-

Capacity(t/h):

-

5-10t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huahong

-

Dimension(L*W*H):

-

900*670*860

-

Weight:

-

600 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

Hummer crusher descripation:

Hummer crusher also named hummer mill, hammer crushers are applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150Mpa. Hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials and compound fertilizer, etc. And hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure. The advantages of hammer crusher are reliable mechanical structure, high productivity and favorable applicability.

Hummer crusher has the advantages of simple structure, large crushing ratio and high production efficiency. the grate gap of hammer crusher can be adjusted according to the user's different particle size requirements.

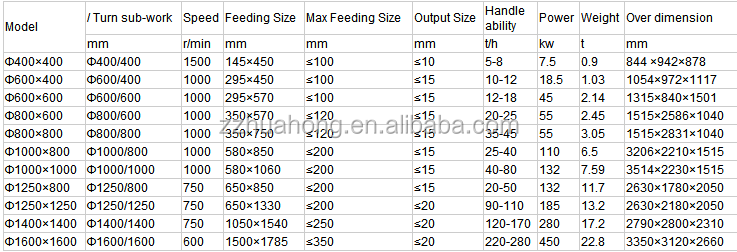

Technical Parameters of hammer crusher:

Features of Hammer Crusher

-Hammer crusher has compact structure and reasonable layout.

-It is convenient to install, and easy to operate and maintain.

-It can crush large, medium and small sized stones, and has high reduction ratio.

-The crushing machine is quite suitable for use in cement plants.

Applications of hammer crusher:

Hammer crusher is widely used in processing plants, refractory plants, cement, glass and other industrial sectors with medium hardness materials are finely ground. Can be used for dry or wet crushing, the material should be seeped before crushing , seepage is not allowed for dry crushing.

Working principle of hammer crusher:

The motor drives the rotor rotates at high speed in the crushing cavity. Material from the upper opening to feed into the machine, under hitting, impacting, shearing, abrasive and high-speed movement of the hammer and can be smashed. the crushed material smaller than the mesh size of the sieve which in the lower part of the rotor discharged , the larger one retained on the sieve and grinding continued to be hit by the hammer, and finally output through the sieve.

|

|

|

Packing :

According to your needs, we can arrange 20GP, 40 GP or other types containers.

Delivery way:

We can choose suitable transport way according to your country and port condition.

Delivery Time:

Shipped in 7 days after place the order

2.Services during the sale:

1.Pre-check and accept products ahead of delivery .

2. Help clients to draft solving plans .

Provide considerate services to minimize clients' worries.

1.Complete After-sales service,professional engineers available to service machinery at home or oversea.

2. 24 hours technical support by e-mail.

3.Other essential technological service.