- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3P or Customized, 380V 50HZ 3phase or customized

-

Power:

-

As required

-

Dimension(L*W*H):

-

As required

-

Weight (KG):

-

5000

-

Product Name:

-

Screw Bolt Mental coating equipment

-

Capacity available:

-

200-3000kg per hour

-

Processing products:

-

nails, screws or metal parts

-

Application:

-

Zinc galvanizing costing

-

Coating color:

-

White, yellow

-

Kinds of coating:

-

Liquid Automatic Coating

-

Control System:

-

Electric Control Box

-

Coating material:

-

Zinc coating, copper coating, etc

Quick Details

-

Machine Type:

-

Electric, Coating Equipment

-

Place of Origin:

-

China

-

Brand Name:

-

Huarui

-

Voltage:

-

380V 50HZ 3P or Customized, 380V 50HZ 3phase or customized

-

Power:

-

As required

-

Dimension(L*W*H):

-

As required

-

Weight (KG):

-

5000

-

Product Name:

-

Screw Bolt Mental coating equipment

-

Capacity available:

-

200-3000kg per hour

-

Processing products:

-

nails, screws or metal parts

-

Application:

-

Zinc galvanizing costing

-

Coating color:

-

White, yellow

-

Kinds of coating:

-

Liquid Automatic Coating

-

Control System:

-

Electric Control Box

-

Coating material:

-

Zinc coating, copper coating, etc

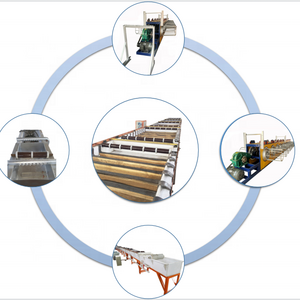

Electroplating line cold galvanizing line Screw Bolt Mental coating equipment

Electroplating Production Line For Hardware

Barrel plating equipment line.

The barrel plating production line has reasonable structure, beautiful appearance, safe operation, low noise and easy maintenance. It is suitable for mass production of various small parts and various plating needs. High production efficiency, uniform plating and good quality.

Roll galvanizing, barrel copper and nickel plating

Rolling line can also be divided into manual line (portable, manual), automatic line (semi-automatic, fully automatic).

Function: for galvanizing all kinds of nails or screws to make the nails or screws more bright and anti-rust.

Each galvanizing line, have Pre-processing tank, Galvanizing tank, Post-processing tank and Drying machine, which can finish a full circle of the electroplating automatically.

Or you can only choose to use the Galvanizing tank to do electroplating, the Pre-processing tank and Post-processing tank, you can build a sink or use some barrels to instead and operating it manually to reduce the cost.

Regarding the galvanizing part, there are different drums/barrel plating tanks for this equipment,each drum can load 70kg-300kg workpieces as your demand, 15 minutes can finish plating one drum of workpieces. Each drum alternatively galvanized.

Main technical parameters:

|

Item |

Model |

Electric Galvanizing line |

|

1 |

Capacity |

210kg-3000kg per hour according to your needs |

|

2 |

Plating tank |

12mm PP board, Steel strengthening, Gearing-down |

|

3 |

Washing, Pickling, etc tank(include discharging) |

12mm PP board, Steel strengthening, Gearing-down, Conductive copper platoon |

|

4 |

Electroplating filter |

18 core |

|

5 |

Plating driver |

2000A 12V |

|

6 |

The total production line includes |

Electroplate power Barrel plating bath Electroplate drying machine Electroplating filter Roller/Drums Bridge Crane |

Contact person: Ada Wang, Whatsapp/Wechat is 0086 13569926370

Auxiliary equipment:

|

Rectifier

Electroplating is an electrochemical process. It goes without saying that the power performance, type,characteristics and other factors will have an important impact on the electroplating process. |

|

|

Filter Electroplating filter is by pumping will have the pressure drops to filter impurities in a barrel, after the filter to remove impurities, so as to obtain high precision clean liquid. |

|

Drying machine

Centrifugal dewatering machine is made of high quality stainless steel plate inside and outside,corrosion resistance,durable.There is a unique three foot pendulumc structure,can avoid the vibration caused by unbalanced load,stable operation,good balance,low noise,high dehydration rate. |

The whole line includes:

Finished Products

Detailed images:

Packaging and shipping

Related products

Screw making machines Automatic nail making machine

Screw/Nail hardening furnace Roofing nail making machine

Any questions, feel free to contact us

Contact person: Ada Wang, Whatsapp/Wechat is 0086 13569926370