- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Girth Gears and Pinions

-

Application:

-

Rotary Kiln /Ball Mill /Cement Mixer

-

Heat treatment:

-

Quenching and tempering

-

Certificate:

-

ISO9001

-

Feature:

-

Large

-

Module:

-

Up to M180

-

Tooth Profile:

-

Super Gear

-

Insepection:

-

Raw material inspection, UT,physical property test,dimension inspect

-

Color:

-

Customized Colors

-

Size:

-

Customer's Drawing

Quick Details

-

Weight (KG):

-

60000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yogie

-

Product Name:

-

Girth Gears and Pinions

-

Application:

-

Rotary Kiln /Ball Mill /Cement Mixer

-

Heat treatment:

-

Quenching and tempering

-

Certificate:

-

ISO9001

-

Feature:

-

Large

-

Module:

-

Up to M180

-

Tooth Profile:

-

Super Gear

-

Insepection:

-

Raw material inspection, UT,physical property test,dimension inspect

-

Color:

-

Customized Colors

-

Size:

-

Customer's Drawing

Products Description

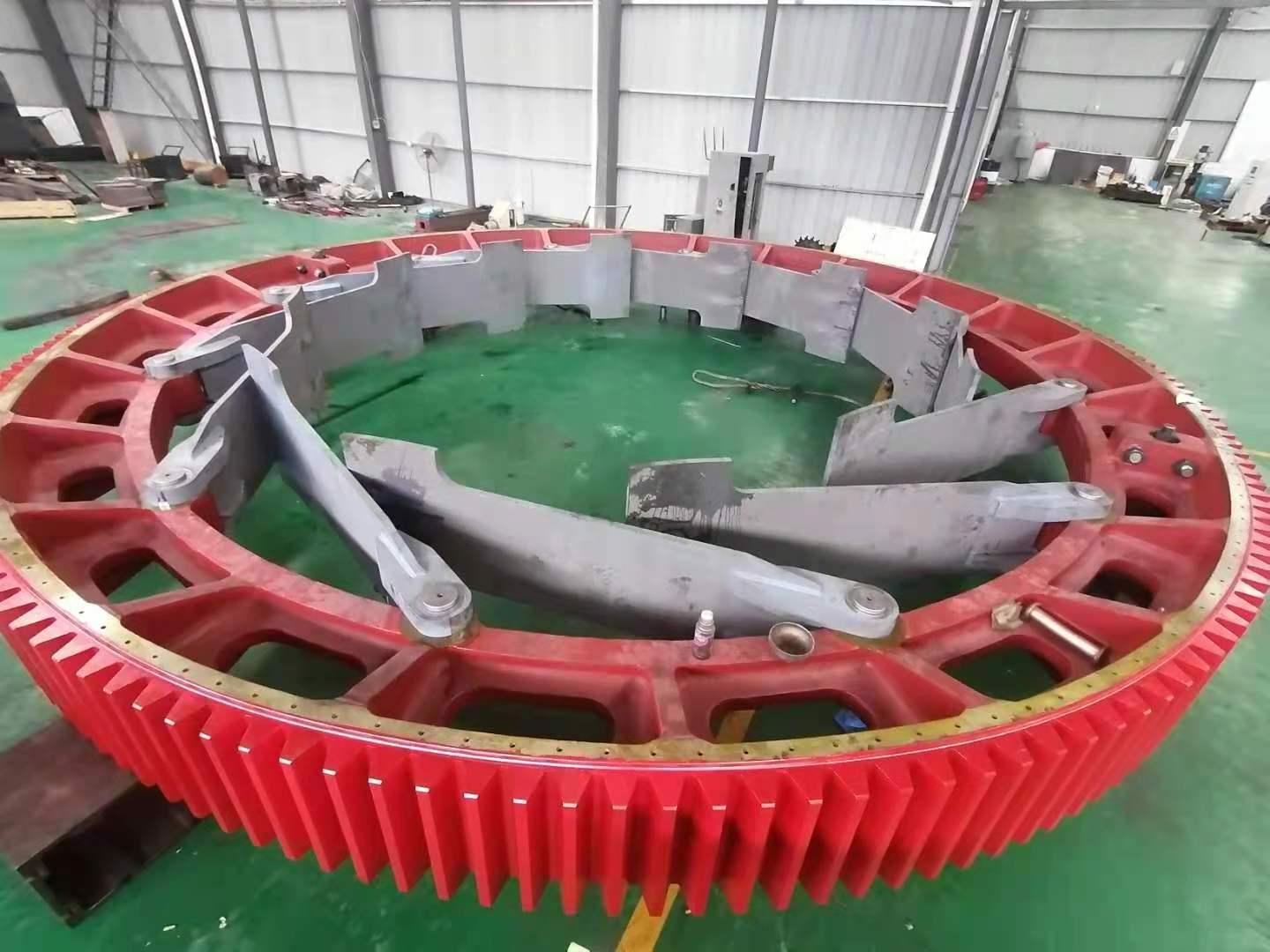

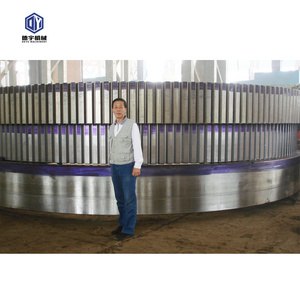

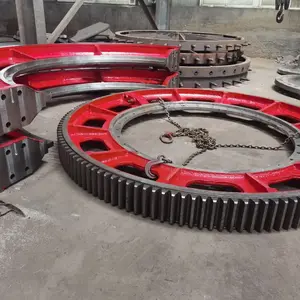

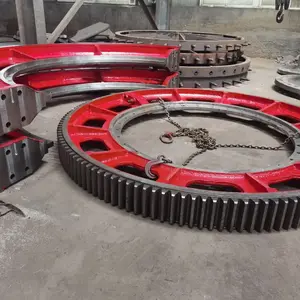

Luoyang Yogie OEM Customized large diameter half girth spur cast steel 45 girth gear for Rotary Dryer

Girth Gears are often used in rotary kiln / cement mixer, which are often forged or cast structure high quality and strength alloy steel with surface carburizing or hardening treatment.The gear have the high bearing capacity and durable.In practical application,which is widely used in high speed and heavy load machinery , because of its stable transmission, low impact, vibration and noise.Our company can produce different type gear ring and wheel such as spur gear, helical gear, herringbone gear wheel and gear ring according to the customer's drawing and requirements. If you have any questions, feel free to contact us.

Application

Gea ring can be widely used in cement plant,rotary kiln, mining, lifting, light industry, chemical industry, transportation, construction and other machinery and equipment deceleration mechanism.

Advantage of Gear

1.Heavy load capacity,long lifespan.

2.High precision,large diameter and module .

3.stable transmission, low impact, vibration and noise

|

Material

|

|

Carbon Steel , Alloy Steel,42CrMo,34CrNiMo,40CrNiMo

|

|

|

|||

|

Standard

|

|

ASTM DIN . EN GOST JIS ETC

|

|

|

|||

|

Workplant

|

|

Forging , Casting and Welding

|

|

|

|||

|

Module of Gear

|

|

20-120

|

|

|

|||

|

Gear Grinding

|

|

MAX Module 25

|

|

|

|||

|

Diameter of Gear Wheel :

|

|

MAX 13 000 mm

|

|

|

|||

|

Diameter of Spiral Gear :

|

|

MAX . 2 200 mm

|

|

|

|||

|

Length of Gear Shaft :

|

|

MAX 5 000 mm

|

|

|

|||

|

Segments Gear Offered :

|

|

2parts,4parts,8parts,12parts or as customer requirement

|

|

|

|||

|

Heat Treatment

|

|

Q&T

|

|

|

|||

|

Gear Teeth treatment

|

|

Surface hardening,cemented and quenching

|

|

|

|||

About us

Luoyang Yujie Industry Trade Co,Ltd is established in 2004,is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, welding, bearings, castings and forgings etc. The products are mainly used in the fields of mining, petroleum, cement,steel mill, power plant, sugar factory etc.

large diameter gear ring,

large diameter gear ring

large diameter gear ring,large diameter gear ring

Quality Control

All tests conform to ISO 9001 quality management system certification standards,supporting the third party inspection commissioned by customer.

arge diameter gear ring,large diameter gear ring large diameter gear ring,large diameter gear

Our Equipment

All our equipment adopts the advanced CNC machine tools,especially large CNC gantry milling and boring machine, CNC floor-type boring machine.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size.It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size.It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

Our company has a series of advanced equipments:XV6032,HXV4032,HXV3017,HXV2017CNC gantry boring and milling machine,TX130CNC floor-type boring machine,DVT-500,HK1600CNC vertical lath,CK6136CNC horizontal lath etc,to ensure high precision and stable performance of products.

Customer Comments

Customer Visit

Certifications

Contact Us

Hot Searches