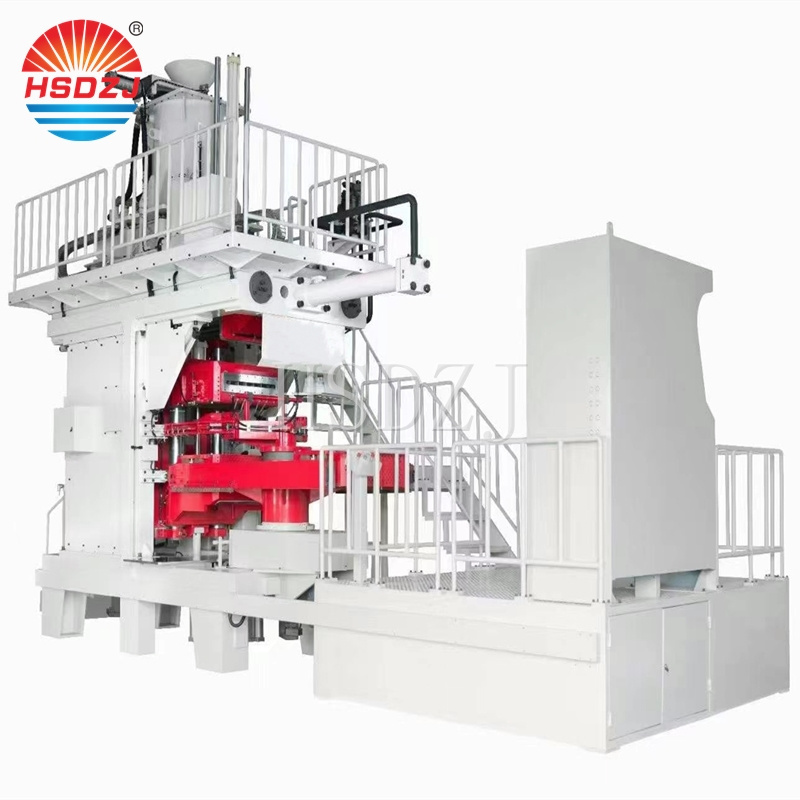

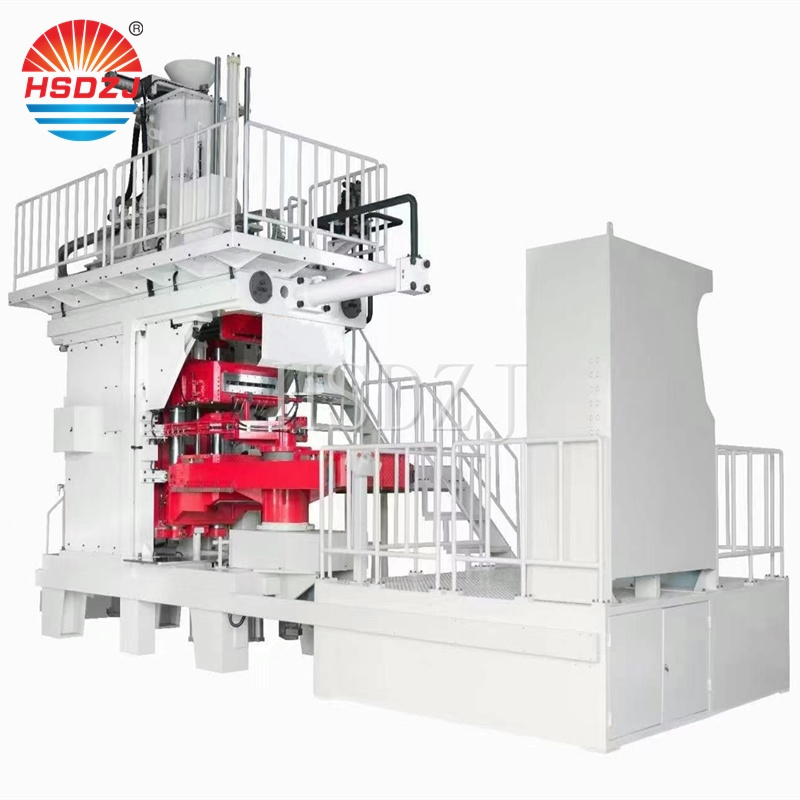

Horizontal moulding line is mainly composed of horizontal flaskless moulding machine and automatic moulding line. With green sand treatment system, automatic pouring machine, dust removal system to form clay sand horizontal casting production line. At present, it is widely used in the metal casting industry, realizing the replacement of manual work by mechanical automation, integrating the functions of automatic feeding, grinding sand, dust removal, recycling of auxiliary materials, product sorting and processing, etc., and the overall process structure design and layout are scientific and advanced; The high degree of automation greatly saves manpower and solves the difficulty of casting labor, and the traditional operation is more than 3 times the existing line automation labor; Strong production capacity, more than 6 times the efficiency of traditional operations; Designed constant temperature automatic casting, unified casting process, to ensure the quality of products; Non-standard parts design and production is reasonable and perfect, no air leakage phenomenon, no dust emission, protect the workshop site working environment, in line with the international atmospheric environmental protection policy.

Machine characteristics

(1)According to the casting structure, it can be divided into SC series side sand shooting model and SX series up and down sand shooting model, which can achieve 1-4 stations at the same time.

(2)Horizontal parting, no sand box, automatic, continuous and efficient, hydraulic compaction moulding, suitable for the mass production of small and medium-sized castings with core and no core in various industries.

(3)The machine has an intelligent human-computer interaction interface and PLC control system, which can adjust and set various technical parameters of the machine on the computer screen, and the faults and problems of the machine will be displayed on the touch screen.

(4)The extrusion sand mold is full without defect, the thickness of the sand mold can be adjusted, the mold closing precision is high, and the station is convenient to fill the coated sand core.

(5)Moulding line adopts imitation machines control, the use of PLC, bit sensor components, pressure sensor components, liquid crystal display and other international first-class brand advanced components, to achieve the automatic and stable operation of the process and dynamic input of the animation monitor, fault inquiry and alarm functions. Remote control is possible. Compared with similar modeling lines, it has obvious progress and advantages in automation control, mechatronic integration level, equipment operation reliability, component wear resistance, synchronous output of the box, pile core, synchronous cooling, automatic sand addition and other complete sets of functions, standardization level and maintainability.

(6)High productivity, high dimensional accuracy of castings, low noise, low labor intensity, simple assembly line, less auxiliary machinesry, small footprint, low process and construction investment, energy saving, is the most advanced and efficient tide moulding sand moulding line.

(1)According to the casting structure, it can be divided into SC series side sand shooting model and SX series up and down sand shooting model, which can achieve 1-4 stations at the same time.

(2)Horizontal parting, no sand box, automatic, continuous and efficient, hydraulic compaction moulding, suitable for the mass production of small and medium-sized castings with core and no core in various industries.

(3)The machine has an intelligent human-computer interaction interface and PLC control system, which can adjust and set various technical parameters of the machine on the computer screen, and the faults and problems of the machine will be displayed on the touch screen.

(4)The extrusion sand mold is full without defect, the thickness of the sand mold can be adjusted, the mold closing precision is high, and the station is convenient to fill the coated sand core.

(5)Moulding line adopts imitation machines control, the use of PLC, bit sensor components, pressure sensor components, liquid crystal display and other international first-class brand advanced components, to achieve the automatic and stable operation of the process and dynamic input of the animation monitor, fault inquiry and alarm functions. Remote control is possible. Compared with similar modeling lines, it has obvious progress and advantages in automation control, mechatronic integration level, equipment operation reliability, component wear resistance, synchronous output of the box, pile core, synchronous cooling, automatic sand addition and other complete sets of functions, standardization level and maintainability.

(6)High productivity, high dimensional accuracy of castings, low noise, low labor intensity, simple assembly line, less auxiliary machinesry, small footprint, low process and construction investment, energy saving, is the most advanced and efficient tide moulding sand moulding line.