- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Voltage:

-

380v or customized voltage

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Product name:

-

multifunctional live fish pet food granular packaging machine

-

Bag type:

-

3 Sides Seal/Back Seal

-

Main Function:

-

Packing Sealing Wrapping Packaging

-

Materials suitable for:

-

fertilizer particles, feed pellet etc

Quick Details

-

Function:

-

FILLING, Wrapping, Sealing

-

Packaging Type:

-

Stand-up Pouch, Bags, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

500

-

Voltage:

-

380v or customized voltage

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QISHENG

-

Product name:

-

multifunctional live fish pet food granular packaging machine

-

Bag type:

-

3 Sides Seal/Back Seal

-

Main Function:

-

Packing Sealing Wrapping Packaging

-

Materials suitable for:

-

fertilizer particles, feed pellet etc

High quality maize milling and packaging machine multifunctional live fish pet food granular packaging machine

Product Description

Introduction :

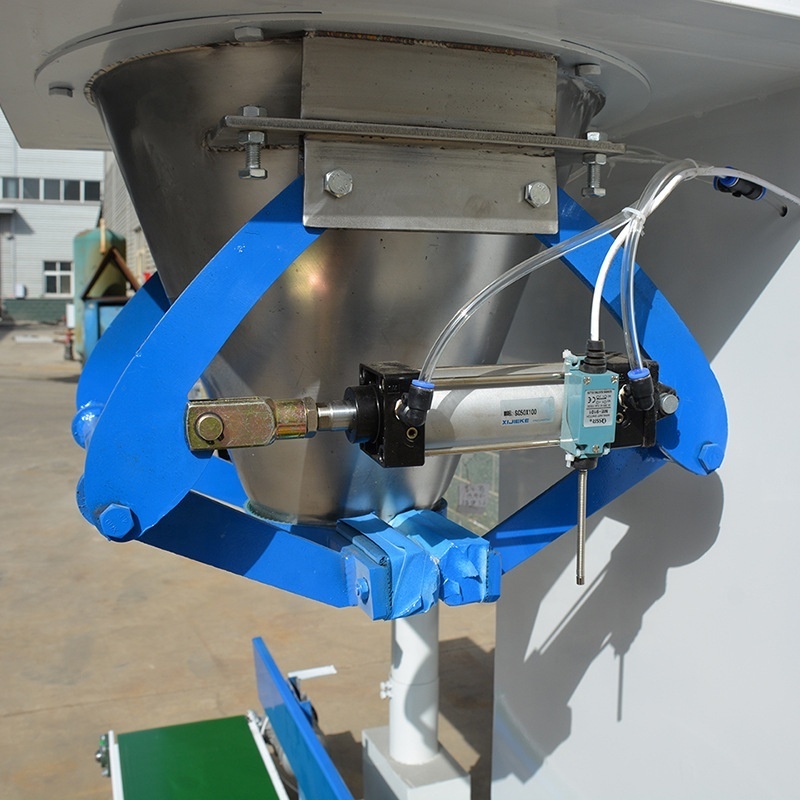

The pellet packing machine is designed according to the national standard GMP, which can finish a sequence of work; weighing, filling, sealing, sewing, deliver and other processes. This packaging machine is suitable for granules in industries such as chemical, feed ,seeds ,food, metallurgy,fertilzier and agricultural by-products, and it is suitable for quantitative packaging of granular materials with good fluidity. For example: fertilizer particles, feed pellet, plastic pellet, corn, peanuts, soybeans, wheat, melon seeds, rapeseed and other food crops, pesticide, granular additive etc. The main parts of machine is made by stainless steel. With the famous brand of the machine body, motor, cylinder, electrical accessories, pneumatic components, pneumatic sealing machine, sewing machine. And the customer could choose the brand by himself.

Automatic pellet quantitative filling machine with screw conveyor are widely applied in chemical&food&feed industry, which is suit for quantitative measuring filling powder item into bags(woven bags, jute bags, paper bags, cloth bags, and plastic bags,etc)

.

Characteristic

1.Adopting imported high-precision sensors and highly intelligent weighing controllers, it has high measurement accuracy and stable performance.

2. Specially designed feeding and bucket metering allow for bagging and unloading without affecting the discharge measurement.

3. Wide quantitative range. High precision, combined with a table top adjustable conveyor sewing machine, one machine is versatile and efficient.

4. Safety design, with safety protection for starting components, electrical appliances, and instruments to ensure equipment and personal safety.

5.Automatic correction of material drop, automatic tracking of zero point, process detection and suppression, and alarm for excessive and insufficient quantities.

Paramemer for reference:

|

Model

|

QS-50

|

|

Filling capacity

|

5-25kg,25-50kg

|

|

Filling speed

|

25-50bags/min,5-10bags/min

|

|

Filling weight accuracy

|

≥99.5%

|

|

Entrainment method

|

Pneumatic entrainment

|

|

Feeding method

|

Spiral feeding

|

|

Cutting control

|

Automatic bag clap control

|

|

Main Power

|

1.1kw

|

|

Sewing machine power

|

0.37kw

|

|

Conveyor power

|

0.37KW

|

|

Machine weight

|

500kg

|

|

Machine size

|

2.3*1.4*3.2

|

|

Remarks

|

Above data is just for reference.Different materials moisture ,density,packing specification and capacity request ,the final parameter may has gap

difference ,Please refer to the actual situation.

|

Recommend Products

Packing & Delivery

Packing: Nude or plywood case or as request

Delivery Date: 7-30 days after confirm the down payment according to order quantity and buyer's request.

Shipping Method: By sea

Shipping Port: Qingdao, China

Why Choose Us

♦Pre-sales:

1 Perfect 7*24hours inquiry and professional consulting service

2.Visit our factory anytime

♦Sale:

1. Update the production schedule in time

2. Quality supervision

3. Product acceptance

4. Shipping on time

♦After-sales:

1. Guarantee:1 year ,during this period we will offer free spare parts if they are broken.

2. Training how to install and use machine

3. Engineers available to service overseas

4. Skill support during the whole using life

Hot Searches