- Product Details

- {{item.text}}

Quick Details

-

Power:

-

4kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1650*950*1450mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

120-150kg/h

-

Raw material:

-

grains powder

-

Material:

-

304 Stainless Steel

-

Motor:

-

Chinese

-

Type:

-

Feed Extrusion

-

Energy:

-

Electricity

-

warranty:

-

1 year

-

shapes:

-

mold customized

-

Product:

-

Dog Cat Pig Bird

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SILK ROAD

-

Voltage:

-

380V/50HZ

-

Power:

-

4kw

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

1650*950*1450mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

120-150kg/h

-

Raw material:

-

grains powder

-

Material:

-

304 Stainless Steel

-

Motor:

-

Chinese

-

Type:

-

Feed Extrusion

-

Energy:

-

Electricity

-

warranty:

-

1 year

-

shapes:

-

mold customized

-

Product:

-

Dog Cat Pig Bird

Factory supplier Dry Dog Food Making extrusion Machine Pet Dog Food Extruder

Contact:Ms sunny

whatsapp/mobile:008618737317087

skype:sunnymachinerysd

wechat:18737317087

QQ:3492521902

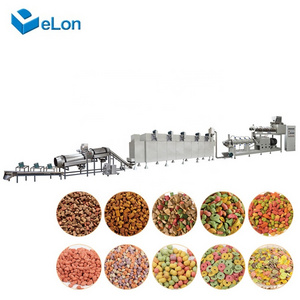

Pet food machine is mainly used for producing pet food,such as dog food,cat food,etc

Factory supplier dog food making machine

Introduction of dog food making machine

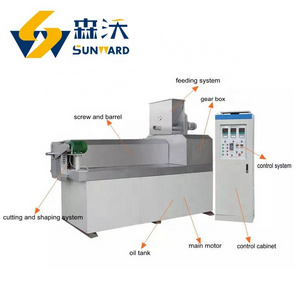

Pet food machine is mainly used for producing pet food,such as dog food,cat food,etc.It is professional pet food machine than carbon steel type.Dog food machine is widely used to puffe grains into high-grade pet food,such as dog food,cat food, aquatic feed pellets for fish, catfish, shrimps, crab,poultry,pig,goat,etc. Puffed feed pellet can help animal digest more easy.According to your capacity and material ,We wil suggest you different model fish feed pellet machine.Dog food dia. can be 1.5-12mm,with different shape.

whole line production line image

Features of dog food making machine

1.Main parts adopt stainless steel and special alloy steel,with heat treatment,long life time than usually machine.

2.Mold can be change easily ,can used for different age of fish,shrimp,etc.

3.Adopt electric heating system improve feed expansion rate and delay the pellets floating time.

4.High temperature puffed process can kill the salmonellosis and bacterial infections,mean while make pellets easily digested.

Working process of dog food making machine

When powder shapes material feed in to silo,it will rotate and help to discharge to screw,screw rotate to convey to the puffed area,here material will puffed to pellet size,after pellet dicharge out from mold,there will be a cutter blades,it rotate and cut feed pellets automatically.

The blades can be adjusted to get different size feed pellet.

Parameter of pet dog food making machine

|

Model |

Capacity (kg/h) |

Power (kw) |

Cutting power (kw) |

Feed power (kw) |

Weight (kg) |

|

SRM -45 |

30-40kg/H |

4kw (220v) |

0.4kw |

0.4kw |

300kg |

|

SRM -55 |

80-100kg/H |

7.5kw(380v) |

0.55kw |

0.55kw |

380kg |

|

SRM -65 |

120-150kg/H |

15kw(380v) |

0.75kw |

0.55kw |

650kg |

|

SRM -75 |

200-250kg/H |

18.5kw(380v) |

0.75kw |

0.55kw |

760kg |

Pet food production line:

1.Mixing process

2.Pet food extruder

3.Dryer

4.Flavor

5.Big capacity need pellet cooler

6.Packing machine

Main extruder machine images

Dog Pet food drying machine images

Pet dog food flavor machine images: