- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3550*1370*4200mm

-

Power (kW):

-

22KW

-

Weight (KG):

-

33000 kg

-

Product name:

-

Hot press machine

-

Layers:

-

5 large 6layers 7 layers 8layers or customization

-

Flow of high pressure pump:

-

25

-

Quantity of cylinders:

-

2

-

Power of low pressure pump:

-

7.5*2

-

Controlling methods:

-

Automatic pump station

-

Electrical appliances:

-

PLC Shneider and Delta plc

-

Methods of frames:

-

Double inlet,double outlet

-

Cylinder:

-

Make in wuxi which is the best brand

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BKS

-

Voltage:

-

380v/415v/customized

-

Dimension(L*W*H):

-

3550*1370*4200mm

-

Power (kW):

-

22KW

-

Weight (KG):

-

33000 kg

-

Product name:

-

Hot press machine

-

Layers:

-

5 large 6layers 7 layers 8layers or customization

-

Flow of high pressure pump:

-

25

-

Quantity of cylinders:

-

2

-

Power of low pressure pump:

-

7.5*2

-

Controlling methods:

-

Automatic pump station

-

Electrical appliances:

-

PLC Shneider and Delta plc

-

Methods of frames:

-

Double inlet,double outlet

-

Cylinder:

-

Make in wuxi which is the best brand

Product Description

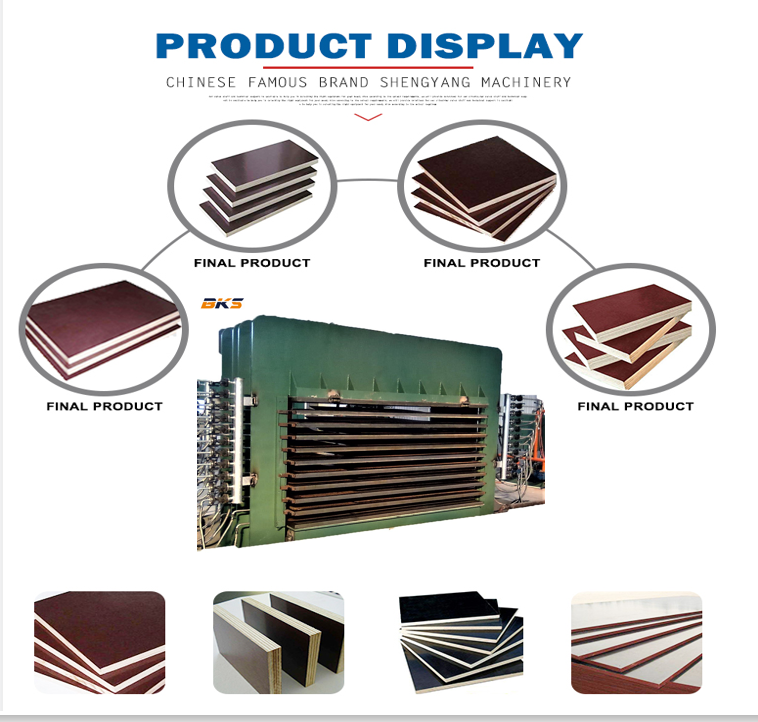

Film faced plywood hot press machine veneer laminating machine for plywood

Plywood hot press machine can also be used for laminating melamine paper on finished plywood .

Plywood is the ideal product widely used in all kinds of furniture,office supplies,combination speaker , packaging exhibition and other industries.

Main sections of plywood production line include peeling section, veneer drying section,gluing section,prepress section,hot press section, saw edge section, sanding section.....etc.

Plywood is the ideal product widely used in all kinds of furniture,office supplies,combination speaker , packaging exhibition and other industries.

Main sections of plywood production line include peeling section, veneer drying section,gluing section,prepress section,hot press section, saw edge section, sanding section.....etc.

Main Features

1) Fabricated structure

2) Multiple daylight openings

3) Uniform heat and pressure distribution

4) Higher heat retaining capacity

5) Hydraulic and electrical components of interantional standards

6)Push button/PLC based controls

Specification

Film faced plywood hot press machine veneer laminating machine for plywood

|

No

|

Item

|

Data

|

|

1

|

Nominal pressure

|

800ton 900ton 1200ton

|

|

2

|

Feeding direction

|

transverse

|

|

3

|

Layers

|

5-10layers

|

|

4

|

Hydraulic cylinder

|

6*280mm*1440mm

|

|

5

|

Quick lifting cylinder

|

2*140mm

|

|

5

|

Openning

|

80 100mm or as your request

|

|

7

|

Closing time of No-load

|

Closing time of No-load

|

|

8

|

Power

|

7.5kw+22kw

|

|

9

|

Size of finished boards

|

915*2150mm,1220*2440mm, 1530*3000mm...etc.

|

|

10

|

Dimension of whole machines

|

3600*1370*4600mm

|

|

11

|

Weight of whole machine

|

33000 kgs

|

Advantages of our hot press machine:

1.Strict controlling management of raw materials, the main frame is welded by standard steel plate.

2.Using domestic and international premium accessories and valve blocks of famous brand, greatly reducing the failure rate.

3.Reasonable structure, convenient operation, beautiful appearance, never cut corners to ensure product quality.

4. High degree autonomy, accessories machinery requiring most can be machined independently through our own production, achieve excellence

5.Timely service, product quality assured.

1.Strict controlling management of raw materials, the main frame is welded by standard steel plate.

2.Using domestic and international premium accessories and valve blocks of famous brand, greatly reducing the failure rate.

3.Reasonable structure, convenient operation, beautiful appearance, never cut corners to ensure product quality.

4. High degree autonomy, accessories machinery requiring most can be machined independently through our own production, achieve excellence

5.Timely service, product quality assured.

veneer laminating machine / Film faced plywood hot press machine / laminating machine for plywood

Details Images

Details

Hot Platen

Main parts-plate

Platen

material is high quality

Q345B.

made by CNC high precision machining center.

Hole tolerance: 0.5mm, Flatness and parallelism tolerance: 0.1/1000.Lmm, Ra 1.6mm

Double input and double output circuit.

Four valves for each oil path.

Oil cylinder.

Main parts-plunger

Wuxi

(alloy material, scratch-resistant)

condensed cast iron solid plunger,

thick-walled seamless steel tube cylinder, forging cylinder

Plunger cylinder diameter(mm): Φ 300*4; Φ190*1

Control system

PLC Control system easy to operate and long life working

Automatic feeding lift table for full automatic hot press machine

Full automatic lift tables used in full automatic hot press machine

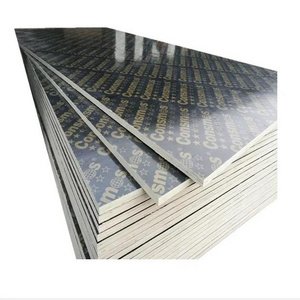

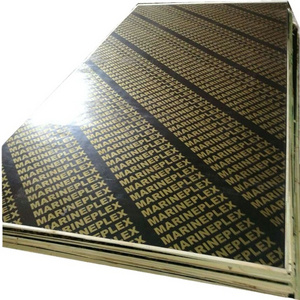

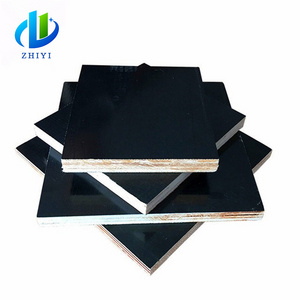

Finished Product

Film Faced Plywood is an exterior Plywood used in building and construction

The black film can give the plywood higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

The black film can give the plywood higher resistance to moisture, abrasion, chemical degradation and fungal attack compared to ordinary plywood.

Hot Searches