- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

110-320V / 50-60Hz / Single Phase-3 Phase

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MicMachinery

-

Dimension(L*W*H):

-

1800*1300*1900mm

-

Weight:

-

1800 KG

-

Product name:

-

Carbonated Drinks Filling Machine

-

Function:

-

Co2 purge, Isobaric filling, Lid seaming

-

Filling type:

-

Isobaric Pressure Filling System

-

Capacity:

-

1000-2000CPH based on 330ml Cans

-

Filling range:

-

250ml, 330ml, 500ml, 8oz, 12oz, 16oz, etc

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Control System:

-

Button control or Touch screen + PLC

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Machinery Capacity:

-

Other, 400BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Other, Aluminum can, Tin can, Pet can

-

Filling Material:

-

Beer, Other, Water, Juice

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

110-320V / 50-60Hz / Single Phase-3 Phase

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MicMachinery

-

Dimension(L*W*H):

-

1800*1300*1900mm

-

Weight:

-

1800 KG

-

Product name:

-

Carbonated Drinks Filling Machine

-

Function:

-

Co2 purge, Isobaric filling, Lid seaming

-

Filling type:

-

Isobaric Pressure Filling System

-

Capacity:

-

1000-2000CPH based on 330ml Cans

-

Filling range:

-

250ml, 330ml, 500ml, 8oz, 12oz, 16oz, etc

-

Material:

-

SUS304/316(Meet GMP Standard)

-

Control System:

-

Button control or Touch screen + PLC

-

Advantage:

-

Easy Operation High Efficiency

Product Overview

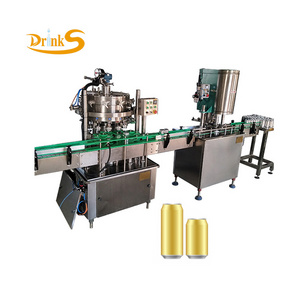

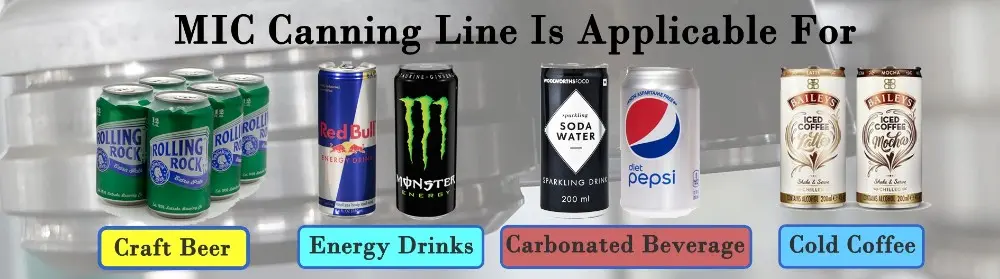

Automatic line soda cocktail wine canning tin aluminum beer can filling and sealing machine

Mic 12-1 carbonated drink can filling machine adopts counter pressure filling system which is applicable for beer, carbonated beverage, soft drink, hard cider, soda water, sparkling water and other canned gas drinks (Cold filling temperature at 0-4 degrees Celsius)

If you also want to use the same machine to fill non-carbonated drinks is available. Through change the counter pressure filling valves to normal pressure filling valves then it will be suitable for filling non-carbonated beverages such as energy drink, fruit juice, cold brew coffee, vitamin water, herbal tea and so on.

MIC-12/1 Features

1. Mic 12-1 carbonated beverage can filling machine is in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit. Filling and seaming part is the overall designed, in order to ensure that both the absolute synchronization and coordination.

2. Isobaric filling system, controlled by pressure, accuracy is +/-1%,liquid level difference is not more than 2mm. (requires steady pressure and temperature at 0-4degrees Celsius).

3. Can seaming machine is qualified for Chinese seaming standard, and no air leakage at all.

4. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can equip CIP system according to the customers’ request. It is the preferred equipment for the small brewery and medium beverage plant

5. Aluminum can and metal can are both available working on our seaming machine, We use our own technical drawing and own processing machine, to make sure our seaming head quality and always easy to purchase.

6. If Cans stock on conveyor then sensor will inform PLC to stop the empty Can feeding in.

Multiple Can Size

The MIC-12/1 can be configured for nearly all available can sizes and widths! Change over between different can dimensions is a snap, requiring only a few simple tools and less than 30 minutes.

PRODUCT SPECIFICATIONS

|

Model

|

MIC-12/1

|

MIC-18/1

|

MIC-18/6

|

MIC-24/6

|

MIC-32/8

|

||||

|

Application

|

Craft beer, carbonated soft drinks, gas beverage, sparkling water, cider, soda water, cold coffee, herbal tea, energy drink, non-carbonated drinks and so on

|

|

|

|

|

||||

|

Packing type

|

Aluminum cans, Tin cans, Pet cans, etc

|

|

|

|

|

||||

|

Capacity

|

1000-2000CPH

|

1000-2500CPH

|

3000-6000CPH

|

4000-8000CPH

|

6000-10000CPH

|

||||

|

Filling Range

|

250ml, 330ml, 355ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L)

|

|

|

|

|

||||

|

Power

|

1.1KW

|

1.5KW

|

3.5KW

|

4.0KW

|

4.5KW

|

||||

|

Size

|

1.8M*1.3M*1.9M

|

1.9M*1.3M*2M

|

2.3M*1.4M*2M

|

2.5M*1.7M*2M

|

3M*1.8M*2M

|

||||

|

Weight

|

1800KG

|

2100KG

|

2500KG

|

3000KG

|

3800KG

|

||||

Details Images

Multi-row empty can feeding conveyor (optional)

Compared with turntable, we will suggest our customer to use this multi-row empty can feeding conveyor. The empty cans are very light, if you use turntable to feeding the cans through the rotating, it will fall down very easily, then block the feeding line.

Inline can rinser / can washing machine (optional)

The inline can rinser is used to clean the empty cans by clean water before filling, we can add this can rinser in the beginning of filling line. The twist cages are customized with your sample cans. As long as the height and diameter of your cans are different, you need to buy the extra set twist cages to change.

Mic isobaric pressure filling system / counter pressure filling system

“MIC” Counter pressuring filling does not create foaming during fill, unless beer is above 40°F. Counter Pressure filling leaves 1.27CM headspace, required by can manufacturers for product expansions and potential warming during distribution. Our machine does not like In-Line filling must foam during filling to clear head space. This type of foaming will creates high dissolved oxygen in head space. Counter pressuring filling does not create foaming during fill. Adopts high precision buffing process and food grade 304 stainless steel liquid tank. It will equipped with CIP connector as customer's demand.

Aluminum lid seaming system

The “MIC” system is a mechanism actuated, cam-driven seamer with easily adjustable rollers that allow for precise adjustment to from seams that are within can-maker specifications. Seams are formed in under only a second, faster than any other system in its class. Through two past decade’s technology innovation and optimization, the result is revolutionary.

Automatic PVC sleeve shrink labeling machine (optional)

If you want to use the blank cans without printed pattern, we can supply the sleeve shrink labeling machine to shrink the label around the aluminum cans. It also including the shrink tunnel and steam generator. Or if you want to use the sticker label to paste the cans, we can also supply the self-adhesive sticker labeling machine for you.

Collection table for finished cans packing (optional)

It will supply enough space for your to collect and pack the cans. It's very convenient for packing work.

More Detailed Photos

Why Choose Mic Machinery

"MIC" Made by o

urselves

Mic machinery Bottling/Canning Systems are 100% designed, engineered and manufactured in Ningbo, China since 1999 using

experience-picked made parts .

experience-picked made parts .

Customer to visit our factory

We devote everything at Micmachinery Filling System with honesty and integrity, which has won us more than 300 customers and

counting in both domestic and abroad. Welcome to visit our factory !

counting in both domestic and abroad. Welcome to visit our factory !

On-call, on-point service

Our online troubleshooting teams will identify your troubles then repair them. They are available for 24hours/7days.Our overseas

engineer team can be carried out to any part of world to fix problems in your line.

engineer team can be carried out to any part of world to fix problems in your line.

Engineering and marketing step by step

We continue to innovate by listening and responding to our customers’ needs. With an emphasis on quality parts and engineering,

MIC has nearly increased by 70% its sales every year since the launch of its first filling system.

MIC has nearly increased by 70% its sales every year since the launch of its first filling system.

You May Need

Activate Your Beer / Beverage Business with Our Expertise, Experience and Enthusiasm

Mic Machinery filling/bottling/canning solutions are tailor-made and precisely engineered to meet each of our customer’s individual needs. We hand-build every system in our facility in zhangjiagang, Jiangsu, China using experience-picked made parts.

Certifications

FAQ

Q1:Are you a manufacturer or trading company?

We are the manufacturer in Zhejiang, we are doing machine production over 15 years, we offer steady machine and 100% machine is running oversea..

Q2:What is the payment way of your company?

① 30% deposit of contact in advance for start production, 70% balance payment should be paid after we video inspection or SGS inspection at site, before shipment.

② 100% Irrevocable letter of credit at sight.

③ To make the machine, we need buyer to provide samples and 30% deposit of contract to start production.

② 100% Irrevocable letter of credit at sight.

③ To make the machine, we need buyer to provide samples and 30% deposit of contract to start production.

Q3:Is this machine in stock or customized for us?

Our machine is customized. Normally, it needs 30-40 days to deliver the goods.

Q4:What is the warranty and the maintenance you can supply?

Two Year Warranty, lifetime maintenance, one year free spare parts shipping. (Not damaged by human factors.)

Q5:How can I install this machine when it arrives at our factory?

We have machine manual which made for each machine, we will have machine test before shipment and make video to teach you how to adjust machine for all process, we are always available for video chat appointment for installation. We are able fly to your site for installation and training.

Hot Searches