- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

YUFA

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7.5 m*1.3m*1.3m

-

Weight:

-

3500 kg

-

Warranty:

-

Within 12 Months

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

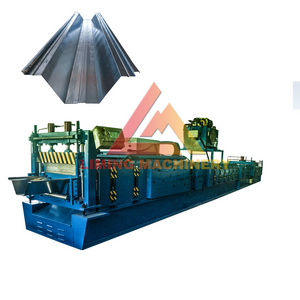

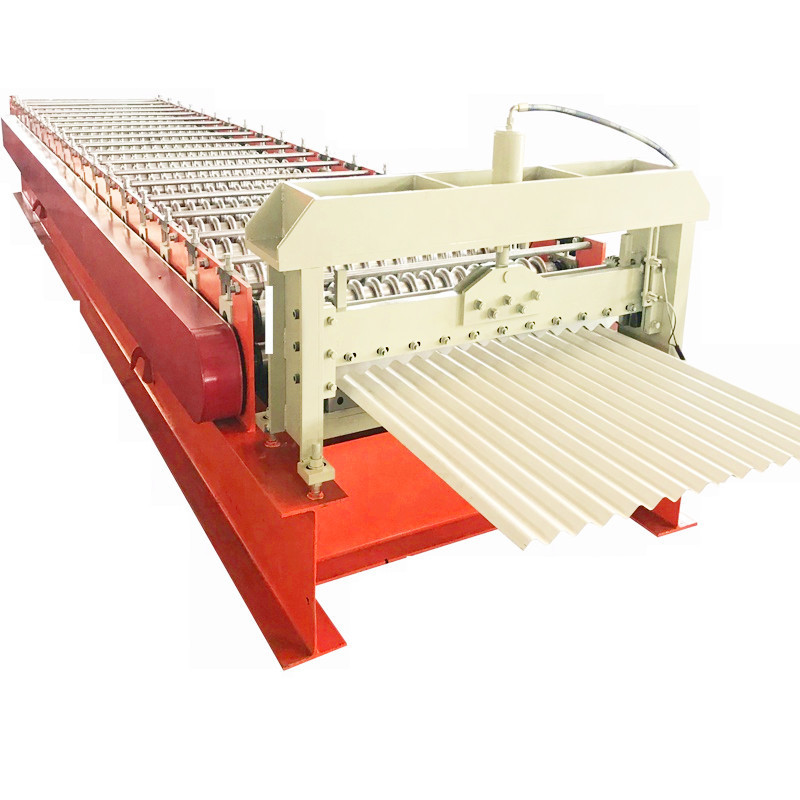

Colour coated corrugated metal roofing sheet machine

-

Power:

-

Hydraulic

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Raw material thickness:

-

0.3-0.8 mm

-

material of cutting blade:

-

Cr12

-

Export port:

-

Tianjin port

-

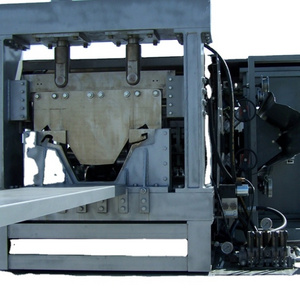

Control system:

-

PLC

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

YUFA

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

7.5 m*1.3m*1.3m

-

Weight:

-

3500 kg

-

Warranty:

-

Within 12 Months

-

Marketing Type:

-

New Product 2022

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Colour coated corrugated metal roofing sheet machine

-

Power:

-

Hydraulic

-

Automation:

-

Automatic

-

Raw material:

-

PPGI/Galvanized sheet

-

Raw material thickness:

-

0.3-0.8 mm

-

material of cutting blade:

-

Cr12

-

Export port:

-

Tianjin port

-

Control system:

-

PLC

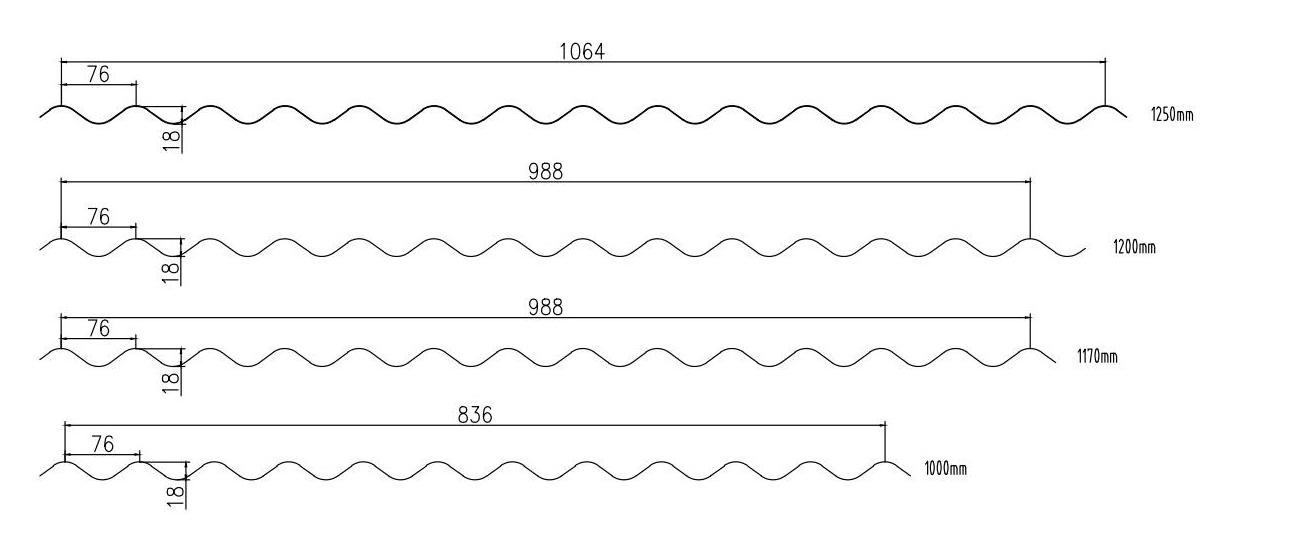

Drawing Maquina calamina de techo manufacturing roof machines manual corrugated sheet machine

| Article No. | Item Name | Specification |

| 1 | Width of feeding material | 1000 mm coil sheet or as request |

| 2 | Thickness of feeding material | 0.3-0.8 mm coil sheet |

| 3 | Roller station | 13 stations |

| 4 | Shaft Diameter | 70 mm |

| 5 | Productivity | 3-15 m/min |

| 6 | Rollers' material | 45# steel with 0.05mm chrome |

| 7 | Shaft material | 45# steel with 0.05mm chrome |

| 8 | Weight | 6.5 ton |

| 9 | length | 6.5 m |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 5 Tons |

| 13 | Motor | 5.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Chain size | 1 inch |

| 16 | Cutting system | Hydraulic cutter |

Manual uncoiler-- roll forming machine-- PLC control box-- hydraulic system- pre cut-- output table

1.CD50/75/100 3in 1 channel profile roll forming machine

3 in 1 c channel machine | multiple c channel machine | C u channel roll forming machine

Multiple C channel machine popular sell in many countries, common thickness between 0.3-0.6 mm, Common speed 10-20 m/min, with servo motor speed can max reach to 30-50 m/min, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

2.CD60/27 & UD27/28 2in 1 channel profile roll forming machine

C Stud and U Track channel 2 in 1 roll forming machine

2 in 1 u stud machine | 2 in 1 metal stud machine | U profile roll forming machine | U stud roll forming machine

To save space and price, some customer like to choose 2 in 1 roll forming machine, it means one machine can produce 2 shapes products. We can customize machine as your need, like

1. Omega profile and u channel 2 in 1 roll forming machine

2. Omega profile and angle bead 2 in 1 roll forming machine

3. Omega profile and C channel 2 in 1 roll forming machine

4. CD and UD 2 in 1 roll forming machine

5. C channel and angel bead 2 in 1 roll forming machine

6. Angle bead and u stud 2 in 1 roll forming machine

Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc.

3.Angle bead roll forming machine

Angle bead roll forming machine | Corner bead production line | Metal angle bead machine | Corner bead roll forming machine | V shape roll forming machine | Steel wall angle bar roll forming machine

Angle bead roll forming machine popular sell in many countries, size common include 20*20 mm, 25*25 mm, 27*27 mm, 30*30 mm. Product thickness common between 0.3-0.6 mm.

4.Omega furring channel roll forming machine

Omega profile roll forming machine | Omega channel roll forming machine | Omega channel roll forming machine | Top hat roll forming machine

Omega profile roll forming machine popular sell in many countries. Product thickness common between 0.3-0.6 mm, we sell lots of such machine to Iraq, Egypt, UAE, Chile, Zambia, etc

5.Small metal sheet line China disposable film slitting machine for aluminum coil

Its used for Omega , C channel ,Angle bead ,U track , metal stud profile sheet .

Slitting machine | metal slitter | sheet metal slitting machine | cheap sliting machine

Simple slitting machine control by motor, it can slitting to any width as your want, more flexible and easy operate. Price cheap, slitting machine width common include 1m, 1250mm, 1.5m, material use PPGI or GI material, thickness between 0.3-0.8 mm

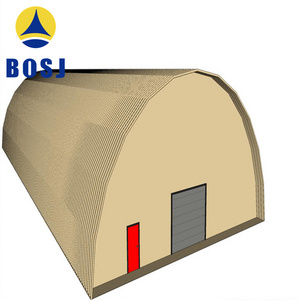

YuFaDa industrial CO.,Ltd is a professional manufacturer designing and producing roll forming machines established in June 1996. We have four factories working in Beijing, Tianjin and Hebei province. More than 400 workers provide service for u.

Products mainly include trapezoidal steel roof/wall panel machine, C&Z shape purline machine, high-way guardrail machine, sandwich panel production line, deck forming machine, C U L light keel machine, shutter slat door forming machine, cutting machine, downpipe machine, gutter machine, etc.

1. Q: How to visit our company:

A: Fly to Beijing A irport : By fast train From Beijing South station to Cangzhou west station

(1 hour ), then we can pick up you to factory(40min) .

Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west

station (4.5 hours), then we can pick up you to factory(40min) .

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material , thickness , voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technicals are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 1 2 months, if the broken parts can't repair , we will send

new parts replace the broken parts free,

but you need pay the express cost if after warranty period

.

we can negotiat

e

to solve the problem,

and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: W e sent technician to your country to fix the machine. B uyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 10 0 USD/day.

I'm not sure if it's for you,but this product line has been selling like hot cakes in Philippines, Egypt, Saudi Arabia, Russia, India, Algeria, Middle East and other countries and regions .

You might want to dig into it a little bit. Contact me!!!