30MnSi Steel PC Bar Production Line

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2023

-

Machine name:

-

PC Steel Bar Machine

-

Delivery:

-

Delivery on time without delay

-

Price:

-

Factory offer price

-

After Sales:

-

Provide solutions within 24 hours

-

Operation Training:

-

both at seller and buyer work site, not less than 7 days

-

Heating temperature:

-

380℃-420℃

-

Speed requirement:

-

speed:≥400m/min

-

Machine model:

-

GZP-300kW/8kHz IGBT

-

DC Power:

-

300kW

-

Frequency Range:

-

6~10kHz

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

RONEN

-

Weight (KG):

-

15000

-

Marketing Type:

-

New Product 2023

-

Machine name:

-

PC Steel Bar Machine

-

Delivery:

-

Delivery on time without delay

-

Price:

-

Factory offer price

-

After Sales:

-

Provide solutions within 24 hours

-

Operation Training:

-

both at seller and buyer work site, not less than 7 days

-

Heating temperature:

-

380℃-420℃

-

Speed requirement:

-

speed:≥400m/min

-

Machine model:

-

GZP-300kW/8kHz IGBT

-

DC Power:

-

300kW

-

Frequency Range:

-

6~10kHz

Company Introduction

Ronen Group

is committed to designing and manufacturing of induction heating equipment, which are widely used in machinery,building materials, metallurgy, papermaking, automobile manufacturing and other fields, to fully meet the needs of steel pipe seam welding, stainless steel pipe welding, strip heating, vacuum melting, copper pipe Welding, steel pipe annealing, refrigerator tube welding, metal heat treatment, metal smelting, welding, brazing, thermal assembly and other induction heating process requirements, mainly include

spring steel wires, high-strength pipe piles PC steel rods / PC bar, Prestressed steel wire, Prestressed Concrete strand, rebar, aluminum-plastic pipes, wires and cables production equipment lines.

Ronen Group

domestic market share is more than 60%, and In recent years, we have exported our machines to

USA, Europe, Russia,Egypt, Japan, Korea etc. more than 25 countries.

Ronen

will always be here for you!

PC Wire Production Machine Description

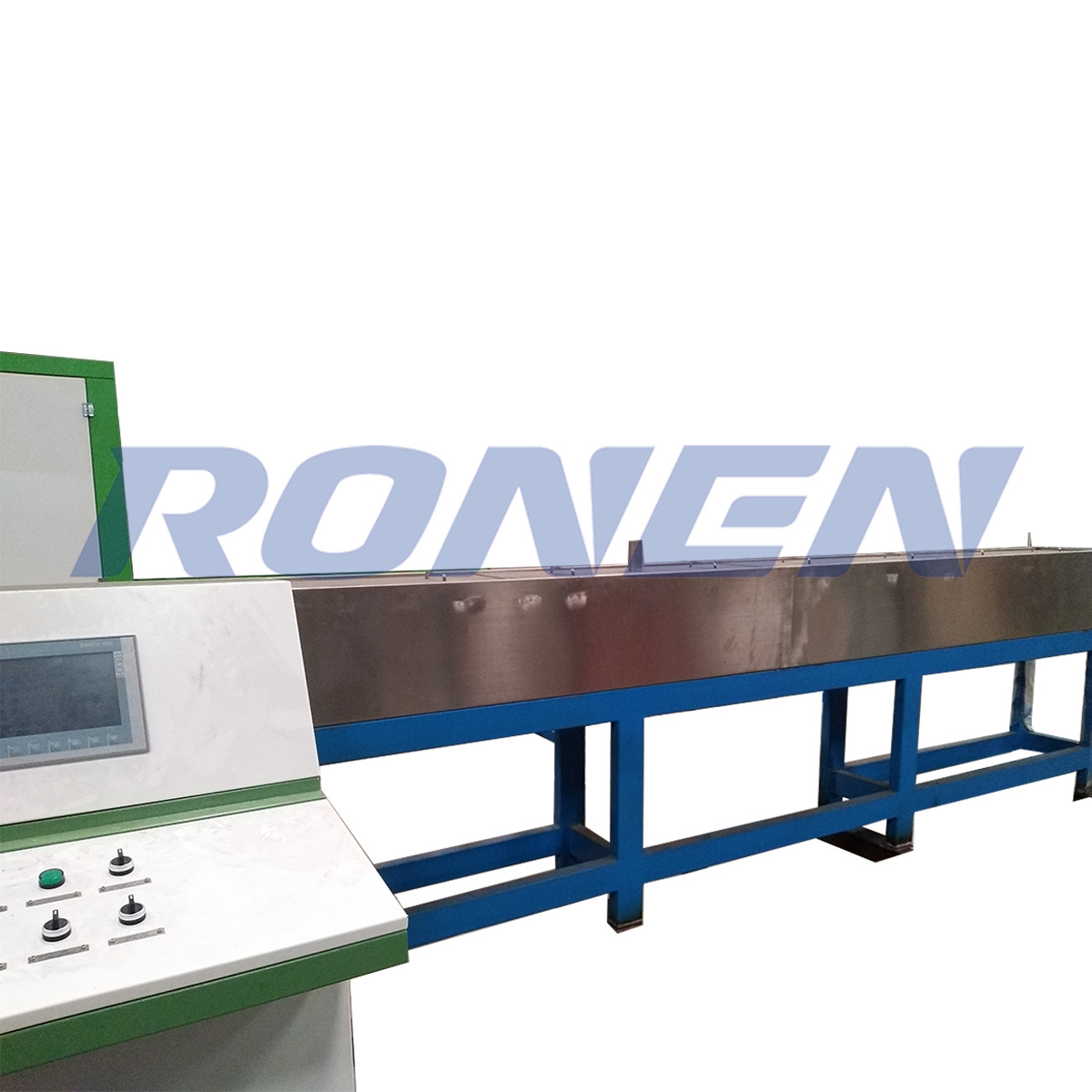

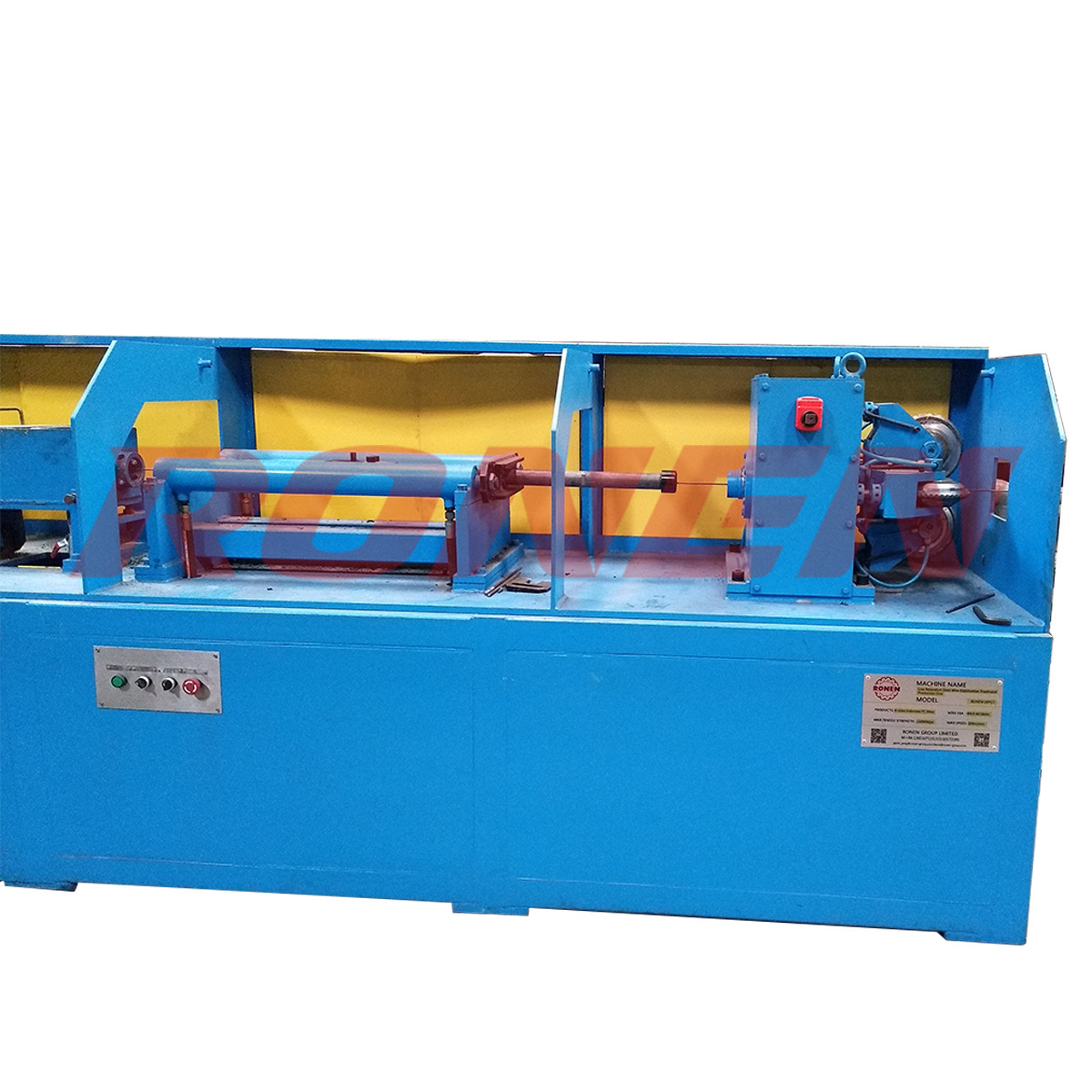

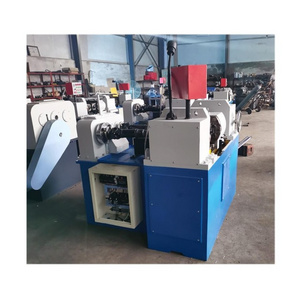

PC Steel Bar Induction Heating Equipment/IGBT Induction Heating Forge Furnace

IGBT Intermediate Frequency Induction Heating Power Supply

PC Steel Bar Production Equipment

Description:

PC steel bar is a kind of prestressed steel with high technical content, which belongs to the intermediate strength level of prestressed strength grade.

Because of its high strength and toughness, low relaxation, strong binding force with concrete, good weldability, upsetting property and material saving (for example, φ 11mmpc steel bar can replace φ 20mm hot rolled steel bar), etc,

It has been widely used in high-strength prestressed concrete centrifugal pipe pile, electric pole, elevated pier, railway sleeper and other prestressed components abroad, and has a very broad market in the world, especially in Asia.

Prestressed Concrete Steel Bar Making Machine

Technical Features:

|

Diameter (mm)

|

Φ7.1

|

Φ9

|

Φ10.7

|

Φ12.6

|

|

Rated Speed (m/min)

|

110

|

100

|

85

|

50

|

|

Output

|

2.07 T/h

|

3.01 T/h

|

3.39 T/h

|

2.94 T/h

|

1. Full digital control with high accuracy and long stable operating performance in long term.

2. PLC automatic calculation and tracking; Acceleration/Deceleration power compensation function; Temperature deviation is small in Acceleration/Holding/Deceleration process.

3.Harmonic frequency and phase automatic precise tracking.

4.Quick and completed limitation and protection of power elements.

5.Rectifier device adopts water- cooling method to reduce fault ratio.

6. Low-voltage start power tracking , Min. start voltage is down to 60VDC, reduce scrap rate caused by machine stop due to low voltage.

7. Man-machine interface(HMI) can monitor and record the operation parameters of the device, and set and save multi-specification parameters.

8. Modular type of inductors, which can be replaced separately without welding.

9.Closed-loop temperature control to improve temperature control accuracy.

10. Communication function: Ethernet communication, can communicate with production line and workshop management system.

Ronen Group domestic & Overseas Customers

Customer Evaluation

Recommend Products

Ronen Group Wrokshop

Ronen Group Exhibition

Equipment Packaging

1.Q:Are you manufacturer?

A:Yes, We are manufacturer.

2.Q: What are the payment terms?

A: Pattern of pattern :we can accept L/C ,T/T , Western Union , Money Gram

3. Q: What is the whole business flow cooperation with us ?

A:1.Firstly,send your inquiry to us,make us have learned your requirement

2.We will be drawing a proforma invoice according to your requirement ,and start production

after you finished to pay 30% deposit.

after you finished to pay 30% deposit.

3.All of the goods, packing details, and B/L copy will be send to buyer after finished production.

We will arrange shipment and provide original B/L after the buyer finished to pay the balance.

4. Q: What if you encounter technical problems?

A:Please contact us as soon as possible and let us know what kind of technical problems you

encounter and the details. We will give you a solution within 24 hours.

encounter and the details. We will give you a solution within 24 hours.

5. Q: What advantages we have?

A: Rich experience: We have been in this line for 20 years . we can provide solution according to the

problem of the buyer meet in the production process

B: We have Adopt first class motor from SIEMENS, install the reasonable welder according to the

requirement of buyer’s production , use the full-automatic grinding control system, eddy current flaw

detection system, infrared testing device.

Ronen Group Website

WeChat

Facebook

Hot Searches