- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong

-

Brand Name:

-

HRT

-

Model Number:

-

HRT-B190

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8500x2100x1600mm

-

Weight:

-

5600 KG

-

Name:

-

Paper Bag Making Machine

-

Application:

-

Food Packaging

-

Speed:

-

30-180 pcs/min

-

Cutting length:

-

190-370mm

-

Paper bag width:

-

80-200mm

-

Paper bag bottom width:

-

50-105mm

-

Paper thickness:

-

50-130g/m2

-

Paper roll width:

-

300-640mm

-

Roll paper diameter:

-

20-1200mm

-

After-sales Service Provided:

-

1 Year

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Shandong

-

Brand Name:

-

HRT

-

Model Number:

-

HRT-B190

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

8500x2100x1600mm

-

Weight:

-

5600 KG

-

Name:

-

Paper Bag Making Machine

-

Application:

-

Food Packaging

-

Speed:

-

30-180 pcs/min

-

Cutting length:

-

190-370mm

-

Paper bag width:

-

80-200mm

-

Paper bag bottom width:

-

50-105mm

-

Paper thickness:

-

50-130g/m2

-

Paper roll width:

-

300-640mm

-

Roll paper diameter:

-

20-1200mm

-

After-sales Service Provided:

-

1 Year

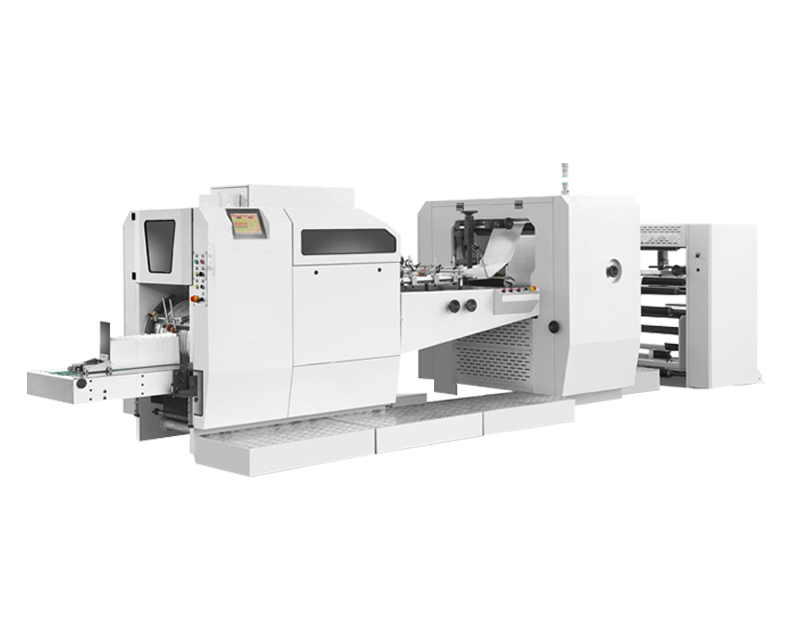

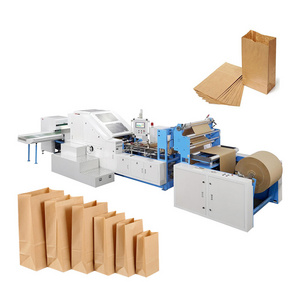

High Speed Roll Feeding Square Bottom Paper Bag Making Machine

Rolling feed square bottom paper bag making machine, it uses paper roll in blank or printed as raw material. consists of automatic centre forward glue, printing tracking, fixed length and cutting, bottom indentation, folding bottom, bottom glue. Bag bottom forming, finished bag collecting one time,The machine is more convenient, more efficient, more stable, can produce a variety of different paper bags, leisure food bags, bread bags, dried fruit bags and so on environmentally friendly paper bag machine equipment.

Main features

1.Use France Schneider Touch Screen Human-Computer Interface, operate and control easily.

2.Adopt Germany Original REXROTH PCControl, integrated with optical fiber, ensure high speed running steadily.

3. Germany Original REXROTH Servo Motor and Germany Original SICKPhotoelectric Eye Correction, tracking printing bag accurately.

Packaging Details:

We usually packed this machine covered by plastic film.

Delivery Detail:

Within 30 days after we got the deposit.

High Speed Corrugated Cardboard UG2-1400B Automatic Carton Box Folder Gluer Machine

High Speed Corrugated Cardboard UF3-1300 Automatic Flute Laminating Machine

Corrugated Cardboard Auto Die Cutter Automatic Die Cutting And Creasing Machine

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes, issued by Italian organization

3.Q:What is the production time while placing order?

A:About 20 days

4.Q:What is the delivery time?

A:15-30days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

6.Q:Does the packing strong?

A:Yes, all packages are double-checking before delivery

7.Q:How about after-sales service process?

A: We offer life time A.S.S. Please feel free to contact after-sales department.

8.Q:Do you have machines in stock?

A: for standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

9.Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

10.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery.

11. Q: Do you accept factory visiting?

A:We are highly greeting for your visiting.

![[JT-SBR180]CE Certificated Fully Automatic Adjustable Roll Feeding Square Bottom Kraft Paper Bag Production Machine](https://cdn.bestsuppliers.com/seo_products_img/jeta/1caf2c64df0636fa8ef9c680e62ff7ab.jpg!/rotate/180/sq/300)